Automatic Intelligent Glass Storage and Sorting System

In the glass production process, after glass tempering and before Insulated processing, the glass specifications are often measured and classified to prepare for the next process. In existing glass production, a glass loading machine is usually used to place the glass on the workbench, and the glass is manually placed on the workbench. The length of the glass is measured and detected, and then a glass unloading machine is used to unload the glass, and the glass is manually classified and stored according to different specifications. If you process insulating glass, you need to sort out and cache the glass varieties and meet the matching needs of insulating glass. However, some deep processing manufacturers still rely on manual patching in existing glass production, which has high labor intensity and increases the error rate of patching.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

Automatic Intelligent Glass Storage and Sorting System

In the glass production process, after glass tempering and before hollow processing, the glass specifications are often measured and classified to prepare for the next process. In existing glass production, a glass loading machine is usually used to place the glass on the workbench, and the glass is manually placed on the workbench. The length of the glass is measured and detected, and then a glass unloading machine is used to unload the glass, and the glass is manually classified and stored according to different specifications. If you process insulating glass, you need to sort out and cache the glass varieties and meet the matching needs of insulating glass. However, some deep processing manufacturers still rely on manual patching in existing glass production, which has high labor intensity and increases the error rate of patching.

Fully automatic glass inspection and film sorting system and its working method, including an automatic loading stage and an automatic unloading stage for automatically loading and unloading glass respectively, and an automatic loading stage and an automatic unloading stage set sequentially according to the process. Among them, there are horizontal and vertical measuring and turning tables, film organizers, and vertical and horizontal turning tables. The automatic film loading table is used to load glass onto the horizontal and vertical measuring and turning table; the horizontal and vertical measuring and turning table is used to rotate the glass from flat to vertical, and measure the length and width of the glass before sending it to the chip sorter; The glass that needs to be output from the slicer is transported to the vertical and horizontal turning table; the vertical and horizontal turning table rotates the glass on it from vertical to flat, and then unloads the glass through the automatic unloading table.

This equipment has complete functions and a high degree of automation, which improves work efficiency and greatly reduces labor; the glass length and width measurement is efficient and accurate, the slice matching accuracy is high, and the glass transportation process has good connectivity and is not prone to scratches.

Working Principle

Fully automatic glass inspection and film sorting production system, including an automatic film loading table and an automatic film unloading table for automatically loading and unloading glass respectively; it is characterized in that: it also includes an automatic film loading table set in sequence according to the process. There is a horizontal and vertical measuring and turning table, a film management system, and a vertical and horizontal turning table between the automatic unloading table; the automatic loading table is used to load glass onto the horizontal and vertical measuring and turning table; the horizontal and vertical measuring and turning table is used to load the glass Rotate from flat to vertical, and measure the length and width of the glass before sending it to the imaging equipment; the glass that needs to be output from the imaging equipment is transported to the vertical and horizontal turning table; the vertical and horizontal turning table will place the glass on it The glass is rotated from standing to flat and then unloaded through the automatic unloading table.

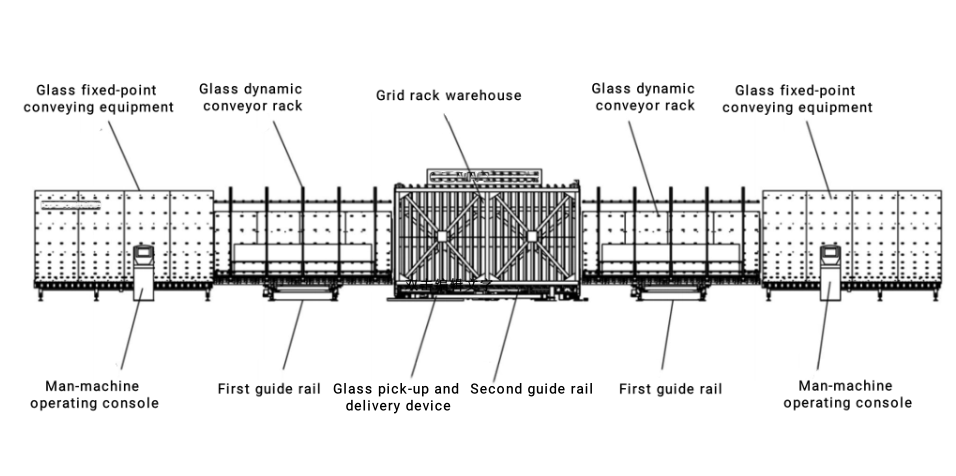

Figure 1 Automatic Intelligent Glass Storage and Sorting System 1

Figure 1 Automatic Intelligent Glass Storage and Sorting System 1

The horizontal and vertical measurement turning table also includes a frame, several synchronous belt conveying mechanisms arranged in parallel with each other, a turning conveying and measuring structure used to rotate the glass from flat to vertical and measure the length of the glass, and a structure for measuring the length of the glass. Glass vertical measuring structure for width measurement; the synchronous belt transmission structure is set on the frame, the flipping conveying measuring structure is hinged with one side of the frame and can rotate around the side; the glass vertical measuring structure is installed on the flipping conveying measuring structure.

Figure 2 Automatic Intelligent Glass Storage and Sorting System 2

Figure 2 Automatic Intelligent Glass Storage and Sorting System 2

The flipping conveyor measurement structure includes a reducer assembly, a flipping frame assembly, a main transmission motor, and a conveying assembly; the reducer assembly is fixed on the frame; one side of the flipping frame assembly is hinged to the frame through a bearing and is driven by the reducer assembly. , the side of the flip frame assembly rotates; the reducer assembly and the flip frame assembly are connected through connecting rods one and two; the flip frame assembly is provided with a photoelectric sensor switch for measurement No. 1 and a photoelectric sensor switch for measurement No. 2. switch and detection glass in place induction switch; two transmission main motors are provided, respectively arranged on both sides of the flip frame assembly. The transmission main motor assembly drives the conveying assembly. The conveying assembly includes a conveyor belt, and drives are provided at both ends of the conveyor belt. pulley, the output end of the transmission main motor is linked to the drive pulley through an idler pulley assembly, and the conveyor belt is supported by multiple No. 1 synchronous pulleys; after the glass on the flip frame assembly is flipped from flat to vertical, the glass bottom is on the conveyor belt.

Figure 3 Automatic Intelligent Glass Storage and Sorting System 3

Figure 3 Automatic Intelligent Glass Storage and Sorting System 3

Figure 4 Automatic Intelligent Glass Storage and Sorting System 4

Figure 4 Automatic Intelligent Glass Storage and Sorting System 4

Equipment Performance

- Adopt scanning and photography technology, can obtain the glass order information from ERP system by reading the two-dimensional code, automatically compares the data and matches to the Insualting glass production line.

- Siemens control system and servo dual-drive control mode are adopted to ensure high-speed and accurate operation of the cage car.

- The track adoptes high precsion rack and straight track to ensure the car running smoothly with low noise at high speed.

- A positioning stopper device is set at the end of the storage cage grid, which is convenient for small size multi-piece glass storage.

- MES system monitors the matching status of original glass pieces of production orders in real time, and orderly outputs them to the next process according to production instructions.

- The storage and sorting system has complete safety protection facilities to ensure safe and reliable operation of the equipment.

- Soft material casing is used to avoid scratches on glass surface in the process of transportation.

Advantages and Benefits

- This intelligent glass storage system solves the problem of temporary storage during glass processing; the information and storage location of the glass entering the warehouse are recorded by the warehouse management system, and then shipped out as needed according to the requirements of the next process;

- The dynamic conveying equipment is connected between the glass fixed-point conveying equipment and the grid rack warehouse assembly of the intelligent glass storage system. According to the requirements of system control, the glass pieces in the glass fixed-point conveying equipment are sent to the grid rack warehouse assembly, or the glass sheets at specific positions in the grid rack warehouse assembly are transferred to the glass fixed-point conveying equipment. The whole process is automatically controlled, saving time and effort, and the control is accurate;

- The swing angle of the movable rack assembly in the dynamic conveying equipment can be adjusted to suit the transmission angle of the glass fixed-point conveying equipment and the angle of the glass storage position in the grid rack warehouse assembly; at the same time, through the conditional swing angle, it can be reduced the wind resistance of walking in the first guide rail increases the transportation speed;

- The movable frame component of the dynamic conveying equipment is equipped with a front guardrail, which can effectively prevent the glass from tipping.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

The Operation Guide of Intelligent Glass Storage and Sorting System

The first fixed bracket assembly includes a fixed support leg, a first rear bracket, and a first rear support bracket. The first rear bracket is tilted backward and is arranged on the fixed support leg. The first rear support bracket is connected to the back side of the first rear bracket. Between the fixed support legs, the first rear support roller is rotated and arranged on the first rear bracket. The outer periphery of the first rear support roller protrudes from the front side of the first rear bracket. The first bottom support roller is located on the front side of the first rear bracket.

The glass storage management and control system includes two human-machine operating consoles, which are respectively located next to a glass fixed-point conveying equipment.

The glass dynamic conveying equipment includes a glass conveying device and a first guide rail. The glass conveying device includes a first-carrying trolley running along the first guide rail and a glass dynamic conveying frame swinging back and forth on the first-carrying trolley.

Figure 1 Intelligent Glass Storage and Sorting System 1

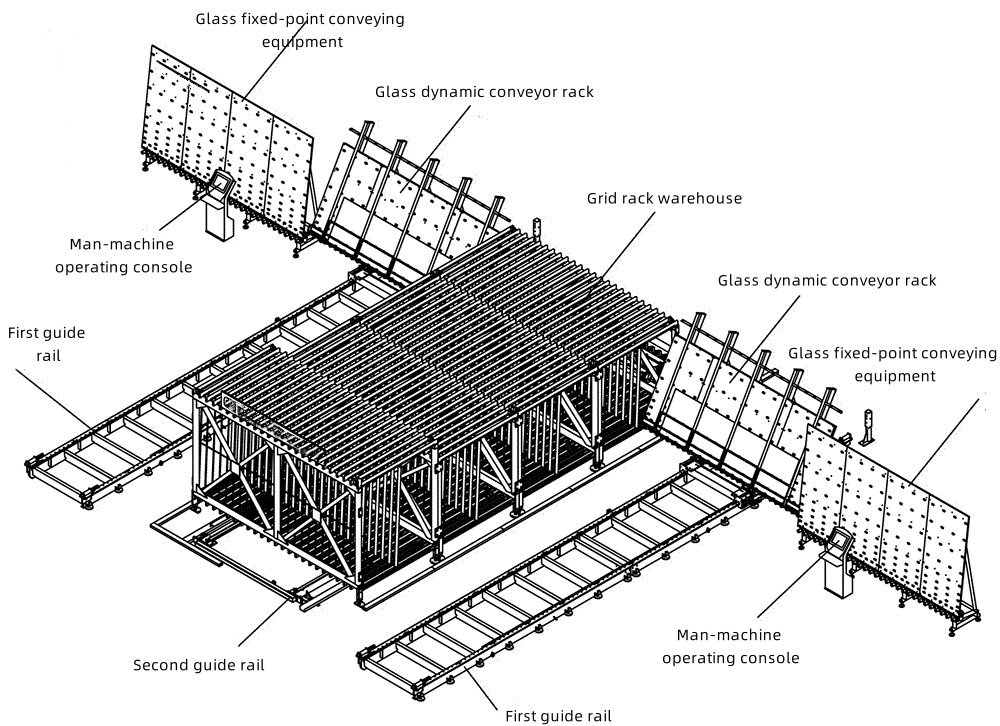

Figure 1 Intelligent Glass Storage and Sorting System 1 Figure 2 Intelligent Glass Storage and Sorting System 2

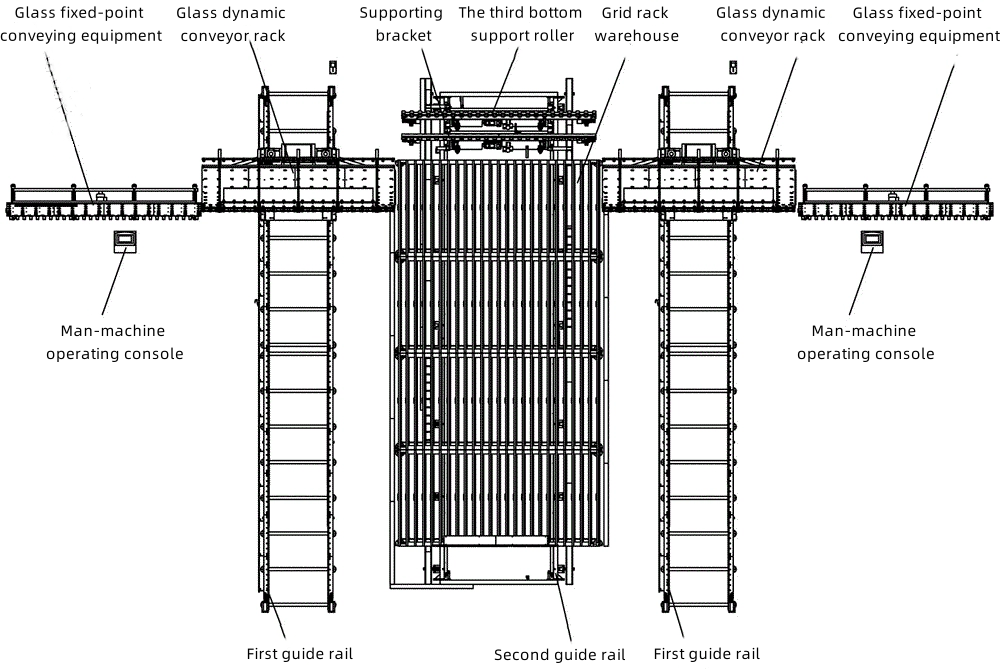

Figure 2 Intelligent Glass Storage and Sorting System 2 Figure 3 Intelligent Glass Storage and Sorting System 3The glass dynamic conveyor frame includes a movable frame assembly, a second roller driving mechanism, a plurality of second bottom support rollers, and a plurality of second back support rollers arranged on the movable frame assembly. The second bottom support rollers are arranged in a linear arrangement, and the central axis of the two bottom support rollers points forward and backward, the second back support roller is arranged on another facade, and the central axis of the first back support roller points up and down. The other facade is a rear inclined surface, and the second bottom support roller The roller or the second back roller is drivingly connected to the second roller driving mechanism.

Figure 3 Intelligent Glass Storage and Sorting System 3The glass dynamic conveyor frame includes a movable frame assembly, a second roller driving mechanism, a plurality of second bottom support rollers, and a plurality of second back support rollers arranged on the movable frame assembly. The second bottom support rollers are arranged in a linear arrangement, and the central axis of the two bottom support rollers points forward and backward, the second back support roller is arranged on another facade, and the central axis of the first back support roller points up and down. The other facade is a rear inclined surface, and the second bottom support roller The roller or the second back roller is drivingly connected to the second roller driving mechanism.The movable frame assembly includes a second rear bracket and a second rear support frame. The second rear support roller is rotatably installed on the second rear bracket. The outer periphery of the second rear support roller protrudes from the front side of the second rear bracket. The bottom support roller is located at the lower end of the front side of the second rear bracket, and the second rear support bracket is provided at the rear side of the second rear bracket; the first carrying trolley is provided with a first support arm and a swing drive device, and the first support arm It is hingedly connected to the second rear support frame; the swing driving device includes a swing control motor, and the swing control motor is drivingly connected to the second rear support frame through a connecting rod assembly.

The connecting rod assembly includes a first connecting rod and a second connecting rod. One end of the first connecting rod is fixedly connected to the rotating shaft of the swing control motor. The other end of the first connecting rod is hingedly connected to one end of the second connecting rod. The other end of the second connecting rod is connected to the rotating shaft of the swing control motor. The second rear brace is hinged.

The movable frame assembly also includes an anti-tip guardrail, which is arranged in front of the second rear bracket, and the anti-tip guardrail and the second rear bracket are separated from each other to form a glass transmission channel.

The anti-tipping guardrail is provided with a plurality of front support rollers. The outer periphery of the front support rollers extends into the glass transmission channel, and the central axis of the front support rollers points up and down.

The first carrying trolley is provided with a driving motor, the rotating shaft of the driving motor is transmission connected with the driving gear, the first guide rail is a linear guide rail, and the first guide rail is provided with a rack meshing with the driving gear.

There are two first guide rails, the two first guide rails are parallel to each other, and the racks are arranged on both sides of the first guide rail. The first carrying trolley is also provided with upper guide rollers and lower guide rollers corresponding to the upper and lower sides of the first guide rail. The guide roller and the lower guide roller are in rolling fit with the first guide rail.

The front and rear ends of the first guide rail are respectively provided with front buffers and rear buffers corresponding to the front and rear sides of the glass conveying device.

As a further solution, the grid rack warehouse assembly includes a grid rack warehouse, a second guide rail, and a glass transfer device in the warehouse. The glass transfer device and the second guide rail are arranged at the bottom of the grid rack warehouse. The glass transfer device in the warehouse is The device includes a second transport trolley and a glass transfer rack in the warehouse. The second transport trolley walks along the second guide rail. The glass transfer rack in the warehouse is lifted and lowered on the second transport trolley; the grid rack warehouse is equipped with a glass rack along the direction of the second guide rail. There are multiple glass storage card positions. The left and right ends of the glass storage card positions lead to the outside of the grid rack warehouse and form the discharge port and the feed port. The bottom of the glass storage card position is provided with a groove corresponding to the glass transfer rack in the warehouse.

The glass transfer rack in the warehouse includes a supporting bracket, a plurality of third-bottom supporting rollers, and a third roller driving mechanism. The third bottom supporting rollers are linearly arranged on the supporting bracket and are drivingly connected to the third roller driving mechanism; The second carrying trolley is provided with a second supporting arm. One end of the second supporting arm is fixedly connected to the second carrying trolley. The other end of the second supporting arm is hingedly connected to the supporting bracket. There is also a second supporting arm between the second carrying trolley and the supporting bracket. There is a lifting drive device used to control the lifting of the support bracket.

The lifting drive device is a lifting driving cylinder. The lifting driving cylinder includes a cylinder body and a piston rod telescopically arranged on the cylinder body. The cylinder body is hinged with the second carrying trolley. The supporting bracket is provided with a connecting arm at the outer end of the corresponding piston rod. The connecting arm is Hinged with the outer end of the piston rod.

The grid rack warehouse includes a frame and multiple rows of fences. The bottom of the frame is provided with a plurality of parallel beams. The beams point forward and backward, and the said giving way is formed between the beams; the fence is connected between the beams and the top of the frame, and the fence is Arranged in parallel front and back, and the glass storage card slots are formed between the fences.

The top surface of the supporting bracket is provided with a groove corresponding to the cross beam, and the groove is used to avoid the cross beam.

The top surface of the beam is provided with soft pads to prevent damage to the bottom edge of the glass piece.

The fence includes steel wires pointing up and down, and the steel wire outer cover is equipped with a roller so that the glass sheet and the fence are in a rolling friction fit.

There are one or two glass transfer devices in the warehouse. When there are two glass transfer devices in the warehouse, glass can be put into and taken out of the warehouse at the same time.