Automatic Glass Washing and Drying Machine

Here you can buy your perfect glass washing and drying machine with a fully automatic CNC control system for every need and budget, whether you're a small business owner or a large industrial manufacturer.

Are you doing research on buying affordable vertical or horizontal glass washer and dryer equipment for glass deep-processing with any budget in USA, UK, UAE, Canada, Australia, Russia, South Africa, China, India, or other countries from Asia, Europe, North America, South America, Africa, and Oceania?

Review 2024 best budget automatic glass washing machinery buyer's guide for glass workers, glass processing machinists, glass fabricators, builders, carpenters operators, craftsman, and beginners.

LIJIANG Glass will offer you 2024 top rated automatic insulating glass processing machines with custom CNC glass cutting, washing and drying, loading and unloading, tempering and Laminating, and insulating service to fit your glass processing projects, plans, and ideas in glass produce and process instruments.

Glass Washing Machine Buying Guide

The LIJIANG Glass Buying Guide are here for you -- there are our go-to recommendations for ultimate question: What kinds of automatic glass washing and drying machine should you buy? There is a collection of buying guides by category.

What is the Horizontal Glass Washing Machine?

The horizontal glass washing machine can clean glass with a minimum thickness of 25 mm, and the minimum cleaning thickness is 1.1 mm, which is suitable for lens glass, mosaic glass, etc.; the maximum glass cleaning range is 2500 mm, and the thickness can be adjusted to 30 mm, which is suitable for large tempered glass, which is thicker furniture glass and so on.

Know More

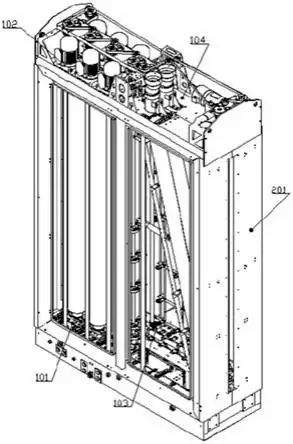

The performance characteristics of vertical glass washing machine

How many features and advantages does the vertical glass washing machine have, simply disassemble the entire vertical washing machine, and analyze the performance characteristics of the vertical cleaning machine from the perspective of mechanical, electrical and PLC control systems...

Know More

What is the difference between vertical and horizontal glass washing machines?

The glass washing machine is a special equipment for washing and drying the surface of the glass before deep processing such as mirror making, vacuum coating, tempering, hot bending, and insulating glass assembling. It can be divided into the horizontal glass washing drying machine and vertical glass washing drying machine. The glass washing machine is mainly composed of the transmission system, washing and drying system, electric control system, and so on.

Know More

What are the characteristics of the current professional glass washing machine?

The requirements of modern industry for glass cleaning machines are constantly increasing. In the process of industrial glass production, especially for glass washing and drying, some glass manufacturers have automatic washing equipment for various types of glass. So, what are the characteristics of the current professional glass washing machine?

Know MoreGlass Washing Machine for Sale

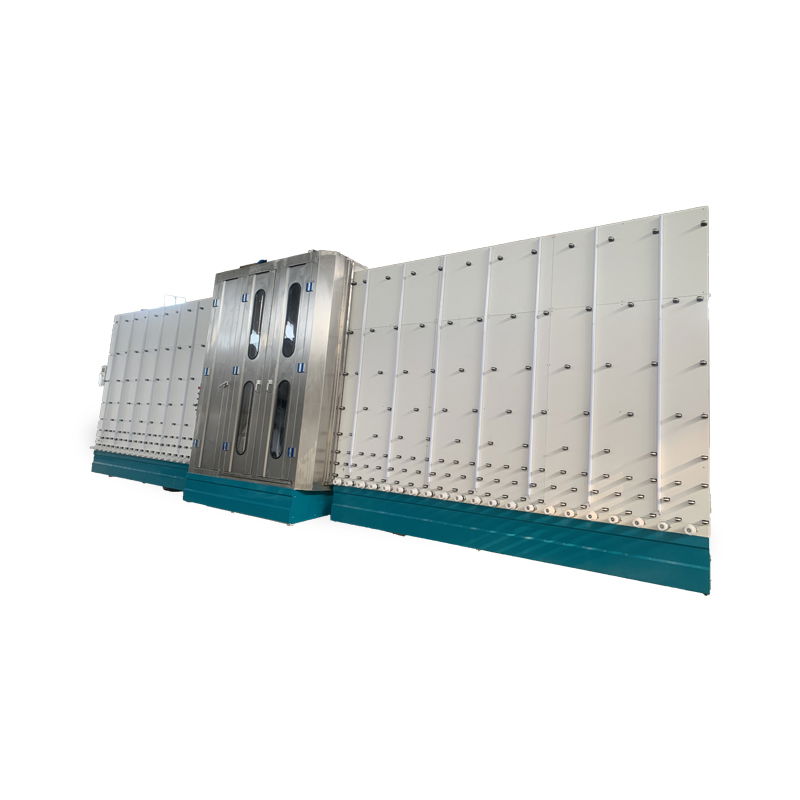

Vertical Glass Washing and Drying Machine

Basic Working Principle

Know More

Detailed Working Steps

- The brush roller in the cleaning part is conveyed by an independent belt of the motor. The brush is made of high-quality acid-resistant and high-temperature-resistant material, which has good cleaning effect and long service life.

- It adopts precise transmission system and frequency conversion speed regulation, which can be operated directly on the panel to adjust the cleaning speed arbitrarily.

- High-quality conveying rubber rollers are densely arranged, which can process different sizes of glass. Combined with gear transmission, the glass transmission is more stable.

- Using an efficient cleaning and air-drying system, glass of different thicknesses can be automatically cleaned and dried; it is cleaned with a brush, dried with a high-quality sponge roller, and then dried with hot air once to ensure that the cleaning effect of the glass is clean and bright without leaving any traces of cleaning stains.

Know More

Technical Parameter

- Max glass size: 2000 mm*2500 mm

- Min glass size: 2500 mm*3000 mm

- Working direction facing the equipment

- Washing speed: 2-10 m/min

- Glass thickness: 3-15 mm

- Insulating glass thickness: ≤40 mm

- Water supply: 0.5 tons/day of circulating water, conductivity ≤40μS

- Washing speed: 2-10 m/min

- Working height: 580 mm

- Power: 3P 380V 50Hz

- Ambient temperature: 10°C-30°C, according to DIN 40040

- Relative air humidity: ≤ 75 %, according to DIN 40040

Know More

Technical Description

Vertical Glass Washing and Drying Machine

Basic Working Principle

- Self-Diagnosis system with touch screen on computer.

- Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input.

- Rotate speed of brush frequency control. (optional)

- Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19 mm.

- High speed cleaning ( max 14 m/min), Low noise ( max 70 dB), high availability working. (25 second /unit)

- Automatic detection of Low-E glass and alarm for coating in reverse. (optional)

- Structure stepped and three-layer I.G. unit available. (optional)

- Precision of plate press: ±0.3 mm

Know More

Detailed Working Steps

- The glass washing machine could clean ordinary flat glass or coated glass with a thickness of 3~12mm;

- The cleaning area uses 3 pairs of brushes or optional 4 pairs of brushes (or imported soft brushes, coating or LOE special), two or four water cleaning;

- The machine adopts an inclined vertical structure, the flat glass is placed on the conveyor roller, passes through the feeding section, cleaning and drying section, and reaching the discharging section to complete the glass cleaning task;

- The cleaning area and the water tank are made of stainless steel and corrosion-resistant materials; the inclined wind knife with strong wind can dry the glass surface;

- The discharge section is equipped with inspection lamps to check the cleaning quality of the glass. The machine is easy to operate, and the operation buttons are concentrated on the operating table.

Know More

Technical Parameter

- Max glass size: 2000 mm*2500 mm

- Min glass size: 2500 mm*3000 mm

- Working direction facing the equipment

- Washing speed: 2-10 m/min

- Glass thickness: 3-15 mm

- Insulating glass thickness: ≤40 mm

- Water supply: 0.5 tons/day of circulating water, conductivity ≤40μS

- Washing speed: 2-10 m/min

- Working height: 580 mm

- Power: 3P 380V 50Hz

- Ambient temperature: 10°C-30°C, according to DIN 40040

- Relative air humidity: ≤ 75 %, according to DIN 40040

Know More

Technical Description

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More

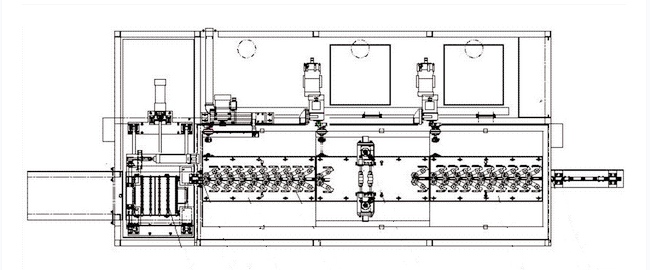

Horizontal Glass Washing and Drying Machine

Basic Working Principle

Know More

Detailed Working Steps

1. Aluminum alloy assembled structure, no scrap concept, permanent use,high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift:350 mm,easy to clean and maintain;

6. Three pairs of brush(Ø 150 mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display, the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10. Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11. Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12. Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

Know More

Technical Parameter

| Item. | Spec. |

| Maximum glass width | 2500 mm (effective maximum: 2650 mm) |

| Minimum glass specification | 400 mm*400 mm (limited to single row on left and right sides) |

| Glass thickness | 3 mm-25 mm (digital display) |

| Speed range | glass thickness within 3-25 mm V max=1-12 m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25 mm |

| Total power | 42 KW(water-bearing wind heating: 15 KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length*width*height) | approximately 6260 mm*4800 mm*3100 mm |

| Weight | 3940 kgs |

Know More

Technical Description

The Imported Components

Using imported frequency converter and PLC control system, the speed of entering and exiting the glass can be adjusted freely, and the processing of clear glass can be maintained at a constant speed for a long time.

The 3 Pairs of Rubber Rollers

3 pairs of rubber rollers are used to press the glass sheets, which can achieve the effect of increasing the pressing strength in sequence, and the glass thickness tolerance is smaller than others suppliers.

The High-power Fan

The washing and drying equipment could be equipped with a high-power fan, the drying effect is better, and the cleaning effect of the glass is fully guaranteed.

The Gradient Pressing Method

According to the direction from the glass input to the output, the glass is gradually pressed by using a gradient pressing method. The pressing effect is better than other suppliers.

Know More

Horizontal Glass Washing and Drying Machine

Basic Working Principle

Know More

Detailed Working Steps

- Horizontal structure, simple operation. The machine frame adopts heavy thickness aluminum alloy to avoid to be out of shape when working for a longtime.

- With stainless steel water sink and high pressure pre-spraying (high pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps.

- Brush: The top and bottom brushes transmit by 1 motor respectively.

- Water tank (with heater):

- 2 water tanks total, 1 for pre-wash, another for washing section.

- Blower: Low noise and vibration.

- Conveying adopts frequent converter, digital display and convenient operation, which do good to connect with double edging line, hollow glass line, safety glass line, etc. Table rollers adapt superior rubber and transmitted by gear wheel which makes a stable working.

- Side covers and tanks and any other water touched material adopt stainless steel 201.

- Washing and Drying section can be lifted to Max. 400 mm by adjustment on electrical board with 4 legs(corners) increasing through motors and encoder.

- 2 pairs air knives adopt advanced technique device, large power and quick air dry.

Know More

Technical Parameter

| Item. | Parameter. |

| Max. width | 2500mm |

| Min. size | 400*400mm |

| Glass thickness | 3~28mm |

| Working table height | 900mm±30mm |

| Blower power | 22kw |

| Total power | 32kw |

| Weight | 3000kg |

| Dimension | 5700*3300*2500mm |

| Low-e require | Yes |

| Water heater | Yes |

| Processing speed | 0.5~12m/min |

| Processing-speed suggestion as follow: | |

| 4mm~8mm thickness, speed suggested to 8-12m/min | |

| 10mm~12mm thickness, speed suggested to 4~6m/min | |

| 15mm~19mm thickness, speed suggested to 2-3m/min | |

| 20mm and more, speed suggested to 0.5-1.5m/min | |

| Item. | Spec. |

| Main machine frame | Aluminum alloy + steel, no deformation. |

| High pressure pump | China famous brand: Shanqing |

| Frequency converter of conveying | China famous brand: Kailida |

| Brush motor | China famous brand: Jinxing |

| Bearing | China famous brand: HRE |

| Electrical Appliance | Schneider |

| Rubber roller | NBR Perduran(sour liquid forbiddion), stainless steel 304 shaft |

| Water tank, sink, side covers, all parts touch water | Stainless steel 201 |

| PLC | Siemens |

Know More

Technical Description

The Aluminum Alloy Structure

The whole cleaning equipment adopts aluminum alloy assembled tripod, which is stable and durable, not easy to change. The surface of the aluminum alloy aluminum profile adopts negative oxidation treatment, which is not easy to be corroded by water.

The Water Tank Adopts #201 Stainless Steel

The water tank, the shield and the place in contact with the water are made of #201 stainless steel, which is harder than #304 stainless steel and contains high manganese. Chromium-rich oxides will be formed on the surface of the steel body to protect the steel body from water rust

The Gear Transmission

The equipment adopts gear transmission as a whole, and the transmission efficiency is high, generally η=0.94~0.99; the transmission ratio has a wide range, especially when planetary transmission is used, the transmission ratio can reach 100-200 (single-stage), which is suitable for deceleration or Speed-increasing transmission; reliable operation and long service life.

The Lifting System

The lifting system is driven by a servo motor, driven by a lifting screw, and combined with a gear drive. It has the characteristics of low friction loss, high transmission efficiency, and high axial rigidity. In addition, the starting torque of ball screw pair is Smaller, there will be no crawling phenomenon like sliding motion, and it can ensure the realization of precise micro-feed and high-speed feed.

The Rubber Roller Transmission

The feeding port and the discharging port of the equipment adopt frequency conversion transmission, and the operation screen is displayed for easy operation. The rubber roller is made of high-quality nitrile rubber, driven by gears, and runs smoothly. It can be connected with edging line, hollow line and laminated line for data connection and unified control.

The Imported PLC Control System

The PLC control system can be equipped with the Taiwan Delta or Germany Siemens control system according to the actual requirements of the customer. The PLC control system can be directly connected to the network, connecting the loading and unloading CNC robots to achieve a smart factory with integrated operation.

Know More

Advantage 1. Improve the corrosion resistance of aluminum profiles

The main component of aluminum alloy profiles is aluminum, which is an active metal that reacts with oxygen in the air to produce aluminum oxide. Due to the uneven oxide film formed naturally, the oxide film is very thin, easily scratched, and has weak corrosion resistance. The artificial oxide film produced by anodizing is uniform, dense and corrosion-resistant.

Advantage 2. Improve wear resistance

The hardness of aluminum alloy cannot be compared with that of steel. The aluminum profile substrate is particularly easy to scratch and wear. The surface of the anodized industrial aluminum profile is very hard and is not easy to scratch by other objects!

Advantage 3. Improved decoration

The base color of the aluminum profile is relatively single, which cannot meet the needs of customers. To improve the aesthetics of the aluminum profile, the aluminum profile processing factory will color the surface of the aluminum profile and anodize the aluminum profile. Thereby, the color of the surface of the aluminum product is diversified.

Customized Demand & Service

Procurement of Other Glass Processing Machine

Most Popular- Purchase other automatic glass processing equipment(such as Tempering Glass Machine and Insulating Glass Machine)and export them together with the same containers. No purchase sourcing cost.

Equipment On-site Installation and Guidance

Most Popular- It is necessary to dispatch some years-experience after-sales services engineers with on-site automatic equipment installation and commissioning guidance 200usd per day with the those terminal users.

Care the Full-life Cycle Maintenance of Equipment

Most Popular- Provide a copy of spare parts and fragile parts commonly used in automatic insulating glass machine and purchase them together, takes responsible for the full life cycle maintenance of automatic glass washing machine.

Re-plan Your Glass Factory Workshop Layout

Most Popular- Based on years+ experience in automatic glass processing, LIJIANG Glass will give customers reasonable suggestions on re-plan your glass factory workshop layout from the perspective of storage and moving, effectively improving...

Make an Appointment for Production

- The main drive of this equipment adopts simons servo frequency conversion motor, and the brush is independently driven, with stable rotation speed and longer service life;

- The digital display shows glass thickness, working speed and other processing data;

- It is equipped with three pairs of brushes and 3 sets of independent water tank chambers, which can effectively wash the Low-E coated glass, and the special wind knife blows the glass with strong wind, which has a better air drying effect.

First, you need to understand your washing needs. This includes the type of glass you need to wash (e.g., flat glass, curved glass, coated glass, etc.), the size and thickness of the glass, and the washing effect you expect. These factors will determine what kind of washing machine you need.

2. Output

Your output needs will also affect your choice. If your output needs are large, you may need a fully automatic, efficient glass washing machine. If your output needs are small, a semi-automatic or manual washing machine may be sufficient.

3. Budget

Your budget is also an important consideration. Fully automatic washing machines are usually more expensive than semi-automatic or manual washing machines. You need to weigh your needs and your budget to choose the equipment that best suits you.

4. Brand and after-sales service

Choosing a well-known brand can usually guarantee the quality and performance of the equipment. In addition, good after-sales service is also very important. If there is a problem with the equipment, good after-sales service can help you solve the problem quickly and reduce downtime.

In general, choosing a glass washing machine that suits your needs should consider your cleaning needs, production requirements, budget, brand, and after-sales service, as well as environmental protection factor.

Sales Promotion & Discounts

LIJAING Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional glass washing machine suggestions for any specific events.