Automatic Insulated Glass Sealing Machine

Affordable Automatic Insulated Glass Sealing Machines For Every Budget In 2024. Just compare features and costs, making your choice easy for both beginners and experts.

Are you doing research on buying affordable insulated glass hot melt sealing robots for glass deep-processing with any budget in USA, UK, UAE, Canada, Australia, Russia, South Africa, China, India, or other countries from Asia, Europe, North America, South America, Africa, and Oceania?

Review 2024 best budget automatic double glazing sealant extruder equipment buyer's guide for glass workers, glass processing machinists, glass fabricators, builders, carpenters operators, craftsman, and beginners.

LIJIANG Glass will offer you 2024 top rated automatic insulating glass silicone or polysulfide sealant coating machines with custom the first sealing and the second sealing of the insulating glass, and insulating service to fit your glass processing projects, plans, and ideas in glass produce and process instruments.

Insulated Glass Sealing Machine Buying Guide

The LIJIANG Glass Buying Guide are here for you -- there are our go-to recommendations for ultimate question: What kinds of automatic insulated glass sealant sealing robot machine should you buy? There is a collection of buying guides by category.

When producing the insulated glass, what kind of sealant should be used for the second seal?

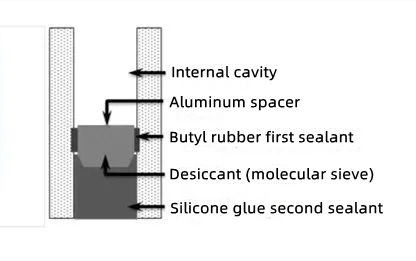

Insulating glass is a product that evenly separates two or more pieces of glass at a certain distance, and the periphery is bonded and sealed, so that a dry gas space is formed between the glass layers. According to the thickness of the gas layer required by the design, a spacer frame containing a desiccant is embedded between the two pieces of glass, and then two seals are performed on the periphery of the glass...

Know More

What are the double seals of insulating glass? What is the role of each?

The insulated glass first sealant uses butyl extruder coating, which has an extremely low water vapor transmission rate; the insulated glass second sealant mainly includes polysulfide sealant and silicone sealant. Insulating glass is always faced with external water vapor penetration and temperature changes during its service life, so it is required that the sealant must first be able to prevent external water vapor from entering the air layer of the insulating glass...

Know More

When the ambient temperature of silicone sealant is low in winter, the viscosity increases, and the sealant is not applied smoothly.

Insulating glass using silicone sealant is composed of chemical raw materials such as silicone rubber, silicone oil, and calcium carbonate. Taking winter in the northern hemisphere as an example, when the temperature drops in the winter in the northern hemisphere, silicone rubber, and silicone oil become thicker, less fluid, and more viscous. This thickening and sticky situation is normal and does not affect product quality.

Know More

The usage guide of insulating glass silicone structural sealant

The guide to the use of silicone structural sealant, including several common key issues during use, what are the reasons for the failure of the bond between silicone sealant and insulating glass, problems of sealant cracking, surface blistering, and wrinkle bulging. The two-component mixture contains bubbles and other problems, and the optimal processing environment for silicone sealant used in insulating glass processing is summarized.

Know More

What are the working principles of the two-component sealant machine for insulating glass?

The insulating glass two-component sealant sealing machine is a key equipment used in the production of insulating glass. It can mix two different sealant sealing materials and evenly apply them on the edge of the glass to achieve sealing of the glass sheet. Its working principle includes sealant sealing supply, mixing and deployment, sealant application, curing, and sealing, which can improve production efficiency and product quality stability.

Know More

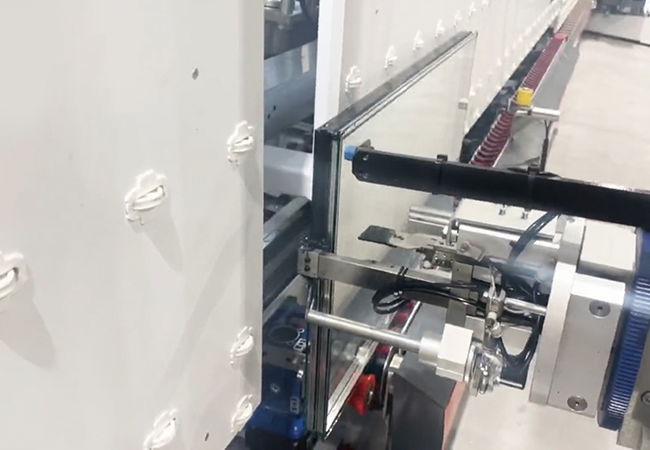

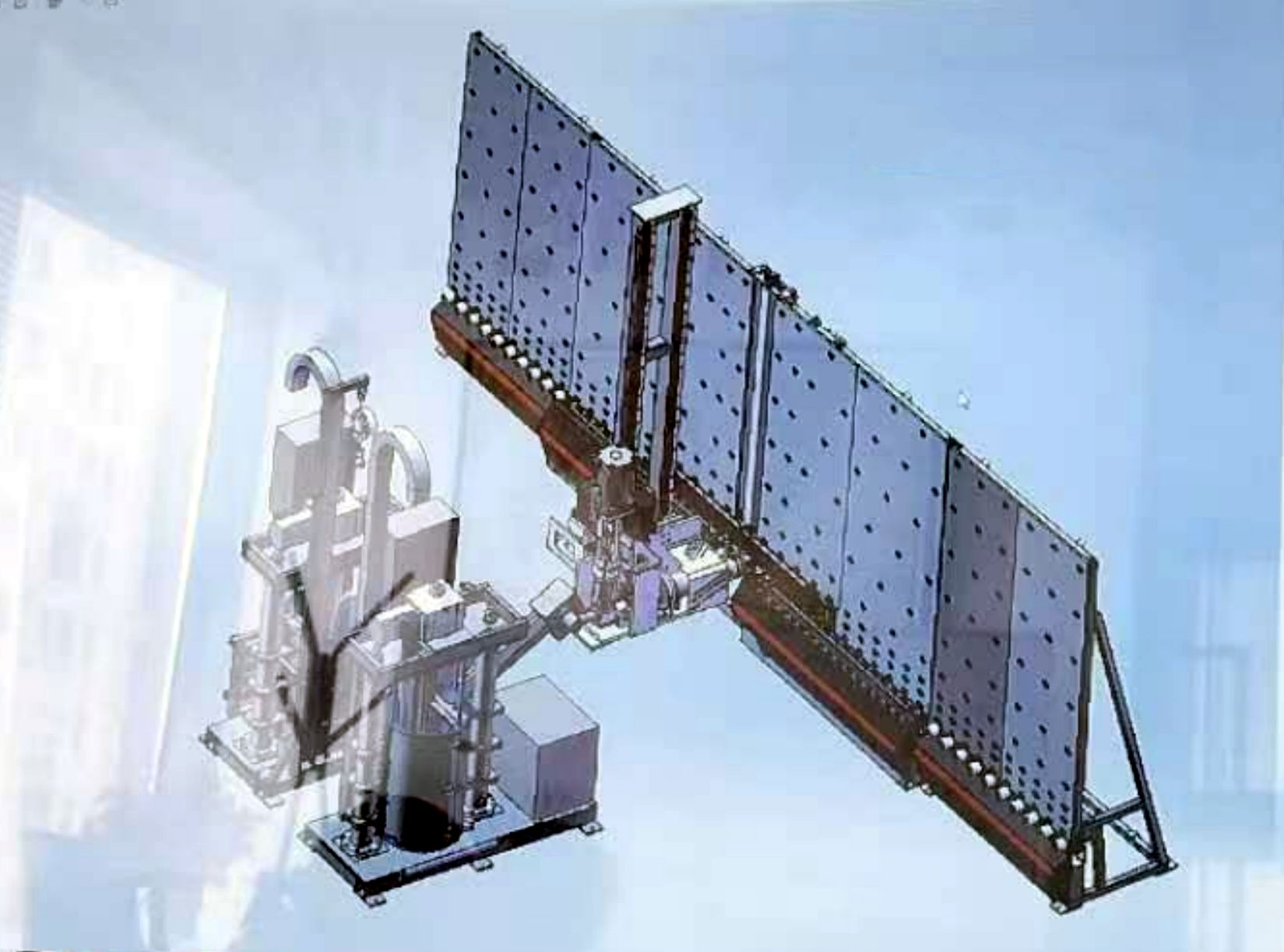

Why we recommend you choose LIJIANG Glass TPS Automatic Sealing Robot Line?

To free you from the inefficient production of manually sealed insulating glass units, LIJIANG Glass has brought a new solution. With the TPS fully automatic sealer, we can upgrade the LIJIANG Glass insulating glass production line with spacer bending, filling, and coating from an entry-level configuration to a fully automatic production line. The main advantage of the new TPSS automatic sealing robot is the reliable gear pump precision sealant dispensing technology, which ensures extremely high sealant dispensing accuracy. This flow-controlled sealant dispensing function can accurately measure the sealant depth and spacer width of the sealant and then apply the required amount of sealant.

Know MoreInsulating Glass TPSS Sealed Antomation Solution

See How LIJIANG Glass TPSS Sealing Solution Compares

Compare Traditional Aluminum Spacer Sealed and TPSS Sealed

While the Traditional Aluminum Spacer Sealed can be a great option for some insulated glass processing businesses, the TPSS (Thermo Plastic Space Sealant for Insulating Glass Unit) offers many of the same powerful features and services as TPSS sometimes at less the a 1000plus of the heat transfer coefficient of insulating glass products. If the budget allows and long-term benefits are important, TPSS glass is a better choice. However, if the budget is limited or aesthetics are not a high requirement, Aluminum Spacer glass is also an affordable choice.

Compare LIJIANG Glass's and other Chinese Suppliers

You may be surperised to learn that while other Chinese Suppliers cost twice as much as LIJIANG Glass for 1,000+ insulating glass TPSS sealing solution contacts, they offer fewer support channels, fewer marketing channels, and fewer marketing features than LIJIANG Glass's Standard Solution for the same aduience. LIJIANG Glass and other Chinese Suppliers both offer marketing support. However, of the two, only LIJIANG Glass offers social media posting, postcards, and websites, while supporting customers on additional channels, like social media and phones.

Automatic Insulated Glass Sealing Robot Equipment

If you're purchasing a new insulated glass sealing robot machine in today's marketplace, you'll find similar products everywhere. Whether you're a novice or an expert, it's hard to pick the best one for your business. You'll have to compare similar features and costs, shop around for the best price, and know how to deal with the transaction. Here are four easy-to-follow steps a buyer would take to purchase a new insulating glass processing machine.

Basic Working Principle

- Adopts Japan Yaskawa servo control system, full automatic and high-efficiency;

- Automatic memory function, no need to input parameters repeatedly;

- Automatically repair glass corners with scraper and roller;

- The conveying section of equipment could be divided into four sections, and glass can be pre-stored;

- Automatically measure glass size and glass depth, adjust sealing speed;

- Adopt timing belt, smooth transfer and accurate position;

- Every automatic-function is with manual operation;

- Could coat the double glazing, shaped glass, step glass, triple glass.

- One set of booster pump control two groups of sealants;

- Automatic timing sealant discharging function;

- The sealant mixing system adopts anti-blocked structure and is easy to clean.

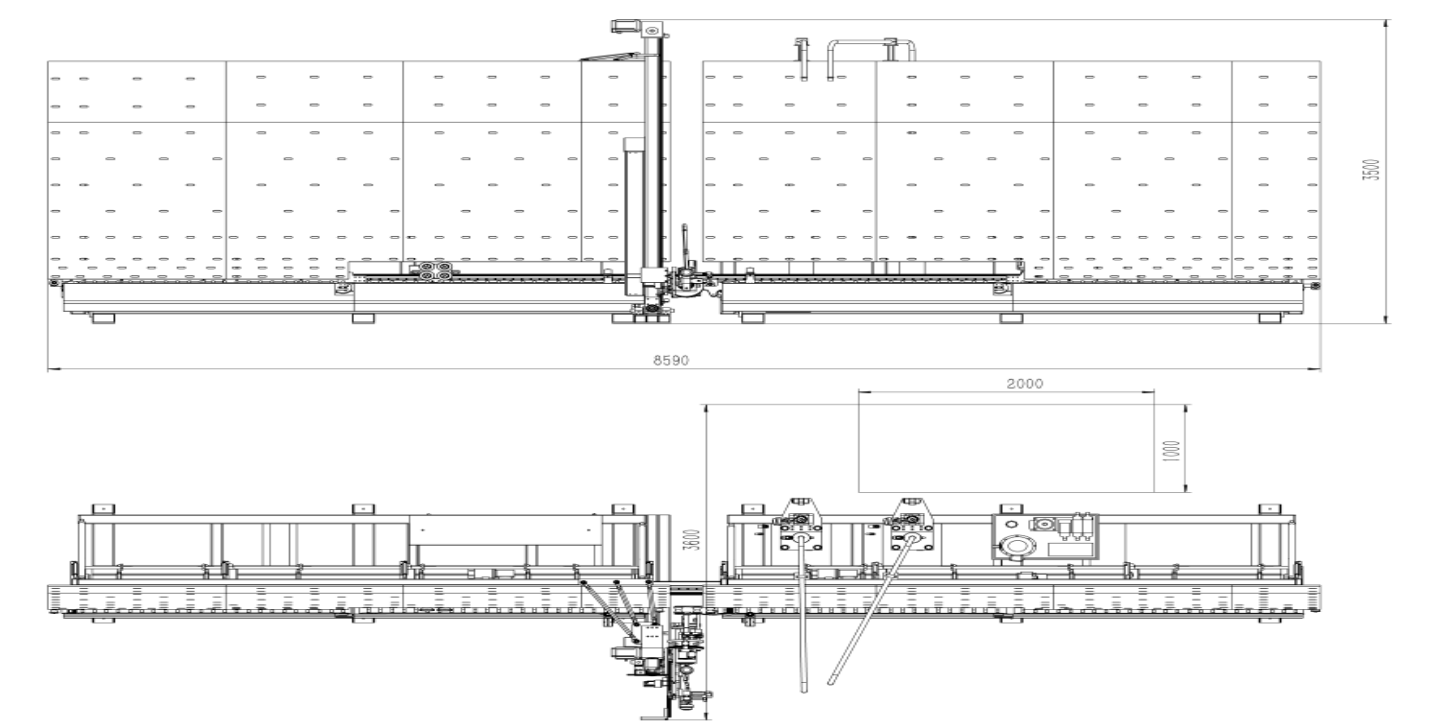

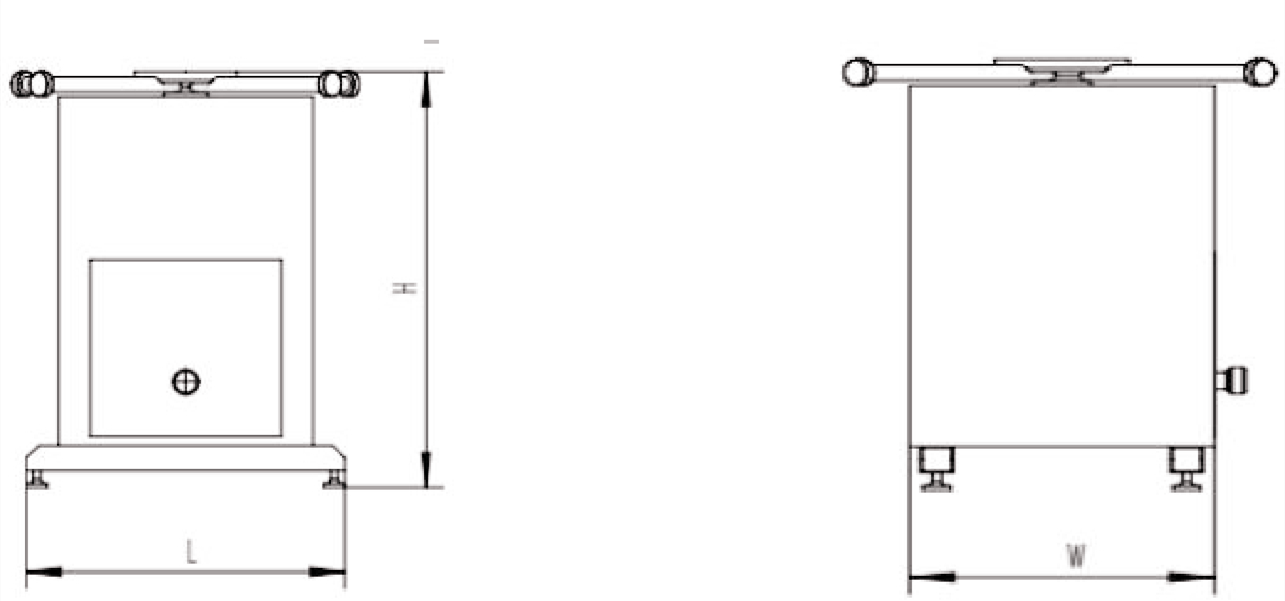

Technical Parameter

| Item. | Spec. |

| Max. Glass Size | 2000*3000 mm/2500*4000 mm/3300*7000 mm |

| Min. Glass Size | 400*300 mm |

| Glass Thickness | 12-56 mm/12-56 mm/12-80 mm |

| Working Speed | 5-40 mm |

| Air Pressure | 0.6-0.8 MPa |

| Squeeze Pressure | <35 MPa |

| Voltage | 380V 50Hz 3P |

| Power | 15 Kw/15 Kw/20 Kw |

| Overall Dimension(L*W*H) | 3700*2500*3000 mm/8700*2500*3500 mm/ 15000*2500*4300 mm |

| Weight | 4300 kg/5000 kg/7000 kg |

Technical Description

Basic Working Principle

- The butyl extrusion speed could reach 47 m/min;

- Saving butyl by compared with ordinary machine, the glue could reach 7 g/m;

- Manual exhaust, simple operation;

- Adopt non adhesive synchronous belt, talc powder is not required to clean it;

- Main accessories are made of German brand, PLC Program control, stable performance;

- Using movable vertical butyl release and horizontal extrusion, convenient and practical;

- Adjust the width of glue head automatically, ensure the double side gluing is consistent with the quick opening value integrated control;

- The height adjustment of beam is convenient, effective to solve the problem of write line;

- Use touch screen operation, simple trial;

- Adjust the butyl output automatically according to the speed change;

- Adopt brand hydraulic system to ensure uniform and full rubber output;

- The buytl cylinder adopts the pull-up structure, which is convenient for changing the butyl extruder coating.

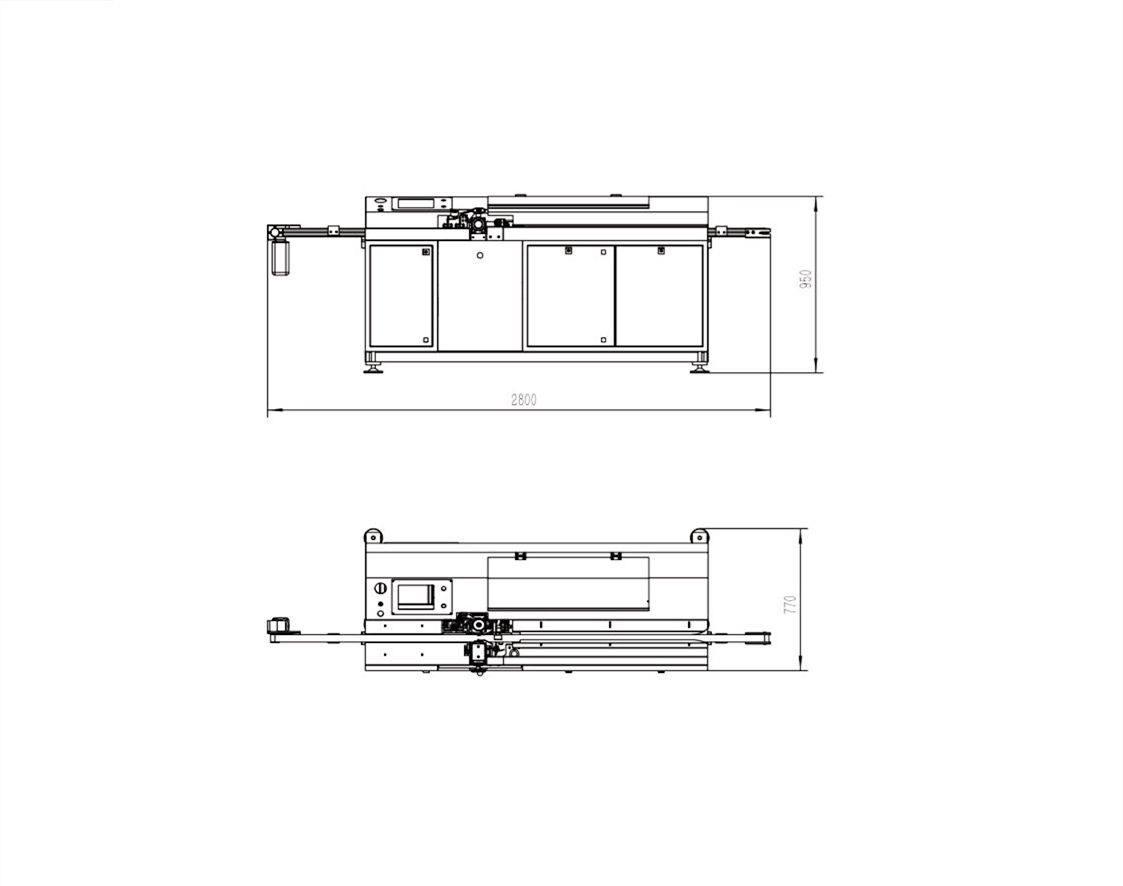

Technical Parameter

| Item. | Spec. |

| Voltage | 380V 50Hz 3P |

| Power | 5.7 Kw |

| Butyl Extrusion Pressure | 10·25 MPa |

| Temperature | 110~140 ℃ |

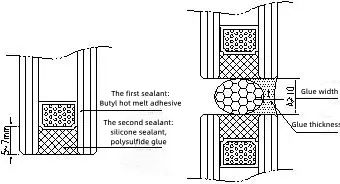

| Glue Thickness | 0.3~0.5 mm |

| Glue Width | 3.5 mm |

| Aluminum Spacer Width | 5.5~26.5 mm |

| Speed | 0~47 m/min |

| Diameter of Butyl Cylinder | 200 mm |

| Air Supply | Flow 0.4 m³/min |

| Air Pressure | ≥ 0.6 MPa |

| Dimension(L*W*H) | 2800*700*900 mm |

Technical Description

LJTB01 Insulated Glass Butyl Extruder Coating Machine

LJTB01 Insulated Glass Butyl Extruder Coating Machine Basic Working Principle

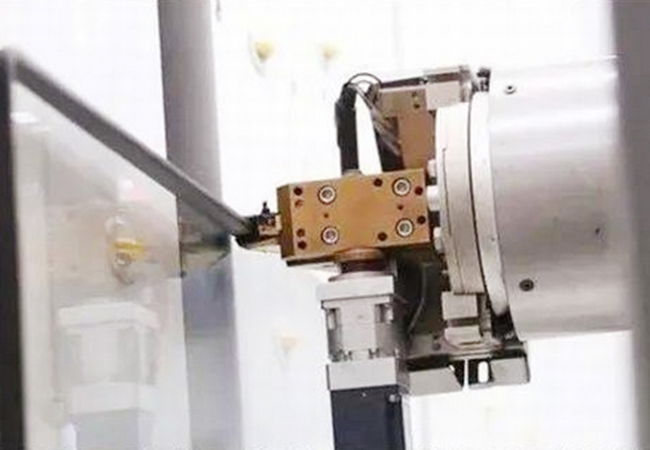

This type Insulated Glass Two-component Sealant-Spreading Machine was designed by advanced technology from abroad and inside of China. It is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structure glue for the aluminum type insulating glass or curtain wall glass. A and B pump adopt Korea brand HASCO.So it can ensure the reliable working-effect.

Special and convenient mixed device can ensure the high quality mixing of the two-component polysulphide glue and/or two-component silicone structure glue. This equipment is featured by uniform mixture and continuous stability of extruded glue, good spreading effect and high production efficiency.

Detailed Working Steps

1.Imported motor system to improve equipment efficiency

2.Imported sealant gun, stainless steel mixer

3.High pressure protect device

4.Mixed rate detector

5.Anti-back flow control structure

6.Important control parts adopt Korea Brand

7.Mixed rate detector can control the rare of two kinds of glue

It adopts the most advanced domestic and international technologies, which is applicable to sealing and bonding of insulating glass and curtain wall glass as well as machinery manufacturing.

The internationally prevailing stationary reciprocating mixer is used in this machine, with the specially designed needle valve, a much better mixing result is achieved; The special material with elasticity is used to make the dispensing nozzle, the production of insulating glass is more convenient, simple and elegant.

The material pump, curing agent pump and proportional pump high pressure valve of the machine are made of special leakage-free alloy by grinding. The proportional pump is installed with an adjustable proportioning mechanism; the nearly fastidious proportioning requirements of the bi component adhesive are fulfilled, as well as those of curtain wall glass and insulating glass.

The curing agent system is fully closed, which prevents the agent from contacting air and therefore solidification occurs. The fluid flow rate stability is ensured and mixing effect improved.

The key functional parts are made of high-tension and quality stainless steel with thermal treatment, the reliability and durability of the machine are greatly improved, ensuring a fairly well quality of machine.

Component A pump and Component B pump are driven by high quality imported pneumatic systems respectively. With the contact-free electrical control system, a reliable and sensitive switching of direction is realized.

Technical Parameter

| Item. | Spec. |

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |

| Weight | 490kg |

| Capacity of the glue drum | 200-300 ml/200 kg |

Technical Description

Basic Working Principle

- Easy operating, simple and flexible.

- It is used for fixing and rotating glass when manual coating the outside of IG glass.

- The middle sucker is suitable for small pieces of glass, however, extra support frame is for large pieces of glass.

Technical Parameter

| Power supply | 380V 50 Hz |

| Total power | 0.37 kw |

| Operating dimension | 1500*1500 mm |

| Dimension | 600*550*985 mm |

Technical Description

LJZT03 Automatic Insulated Glass Sealant Spreading Rotated Table

LJZT03 Automatic Insulated Glass Sealant Spreading Rotated Table Basic Working Principle

By applying TPSS/4SG sealing technology, insulating glass manufacturers can easily update their production methods by replacing new sealing system solutions or adjusting existing insulating glass production lines.

- The double sealant barrel system ensures uninterrupted glue supply operation, and the sealing in the sealant barrel can be replaced in time during the production process when it is used up;

- The width of the spacer is replaced with an asymmetric three-layer insulating glass spacer, and there is no need to interrupt production when switching;

- Eliminates the bending, sawing, and connection of individual spacers, the filling of molecular sieves, and the coating of butyl extruder;

- The production company does not need to store spacers of different types and specifications and does not need to store molecular sieves.

- The production of insulating glass will not be interrupted due to the loss or error of the spacer frame.

- It can be applied to the production of insulating glass with four sides, two-glass and three-glass insulating glass.

- The maximum production size can reach 9m long.

For Glass Doors, Windows and Structural Curtain Walls Production

TPSS sealing technology provides optimal energy efficiency.

- 12% lower thermal conductivity than aluminum frame spacers;

- Linear thermal conductivity of glass edge area decreased by 60%;

- Can be sealed according to customer specified position, for example, corner joint sealing

- Suitable for rectangular and any free-form production;

- The wind pressure resistance life of fully sealed TPS insulating glass is 35 times higher than that of traditional insulating glass units. Reliable sealing performance to prevent air leakage at the corners of the glass;

- Good quality can be used for bonding the surface of glass curtain walls;

- UV-resistant, airtight insulating glass edge sealing is suitable for silicone structural adhesive sealing;

- Make indoor and outdoor temperatures evenly distributed on the glass surface, reducing energy consumption;

- Greatly reduce condensation of insulating glass.

For Those Architects and Developers

Propose your ideas, and TPSS sealing technology provides corresponding solutions. Free design without being restricted by technical barriers.

- Design is not limited to the shape and size of doors and windows;

- The color of the window frame is reflected on the thermoplastic spacer, and the visual appeal of the glass and frame mixture;

- TPSS sealing technology has multifunctional performance, high-efficiency insulation, fire protection, hollow partition, heat preservation, reduce condensation and other phenomena, and reduce carbon dioxide emissions.

Detailed Working Steps

- The distribution operations of bending, sawing, connecting, filling and butyl coating of individual spacers are eliminated, and the warehouse storage is simplified to the maximum extent;

- There is no excess material, dust or waste in the insulating glass production process;

- A TPSS automatic sealing production line can flexibly produce various orders;

- With LIJIANG Glass loading and unloading solutions, it provides fast stacking and storage sorting.

Technical Parameter

| Countries or Regions | Certification |

| Europe | EN 1279, Part 1-6 |

| Germany | DIN 1286/1, DIN1286/2 |

| France | NF P 78-451, NF P 78-452, Avis Technique |

| Finland | SFS 4704 |

| Netherlands | NEN 3567 |

| Norway | NS 3212 |

| Italy | UNI 10593 |

| North America | ASTM E2190 |

| United States | ASTM E 773, ASTM E774, HIGS |

| Canada | CAN 2-12.8-M76 |

| Japan | JIS R 3209 |

Technical Description

LIJIANG Glass TPSS/4SG Sealing Robot Line

LIJIANG Glass TPSS/4SG Sealing Robot Line Customzied Demand & Service

Procurement of Insulating Glass Auxiliary Materials

Most Popular- Purchase other insulating glass processing accessories (such as Aluminum Spacer Strip Bars or Buytl Extruder Silicone Sealants) and export them together with the same containers. No purchase sourcing cost.

Equipment On-site Installation and Guidance

Most Popular- It is necessary to dispatch some years-experience after-sales services engineers with on-site automatic equipment installation and commissioning guidance 200usd per day with the those terminal users around the world.

Care the Equipment's Full-life Cycle Maintenance

Most Popular- Provide a copy of spare parts and fragile parts commonly used in automatic insulating glass equipment and purchase them together, takes responsible for the full life cycle maintenance of those insulating glass equipment.

Re-plan Your Factory Workshop Layout.

Most Popular- Based on years+ of experience in insulated glass processing, LIJIANG Glass will give customers reasonable suggestions on re-plan your factory workshop layout from the perspectives of water, electricity, and argon gas, effectively improving...

Make an Appointment for Production

Sales Promotion & Discounts

LIJIANG Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional insulated glass sealing robot machine suggestions for any specific events.

All About the Insulating Glass Sealants

The insulating glass sealant is a extruder coated strip used to seal insulating glass. It is a polymer composite sealing material with weather resistance, aging resistance and low temperature resistance. However, if the insulating glass is not sealed firmly, it will be breathable and affect the thermal insulation effect. Therefore, the sealing treatment of insulating glass is very important, which can effectively improve the thermal insulation performance and sound insulation effect...

What types of insulating glass sealants are generally divided into?

Insulating glass sealants could usually be divided into two types: hot melt type and chemical curing type. Hot-melt sealants are usually butyl hot-melt sealants, and chemical-cure sealants are usually polysulfide sealants, silicone sealants, and polyurethane sealants. Generally speaking, butyl hot-melt sealant is mostly used for the first seal of insulating glass, and chemical curing adhesives such as polysulfide and silicone are mainly used for the second seal of insulating glass.

What are the requirements for the secondary sealant of insulating glass?

(1) It has a certain bonding strength and elasticity, enough to withstand the deflection and deformation of the insulating glass due to the air pressure difference, and prevent the deformation of the insulating glass from exceeding the displacement tolerance of the butyl sealant.

(2) It has good air tightness and aging resistance, which ensures that the insulating glass has a long service life.

(3) Polysulfur insulating glass sealant or silicone sealant is used for the secondary sealant of the exposed frame glass curtain wall; silicone structural sealant is used for the secondary sealant of the hidden frame, semi-hidden frame, and point-supported glass curtain wall.

How many types of insulating glass secondary sealant?

Polysulfide sealant is an elastic sealant prepared from liquid polysulfide sealant as the base polymer and adding curing agent and additives. It has good air tightness and is mainly used for sealing framed insulating glass, such as insulating glass for doors, windows, and exposed frame curtain walls.

Silicone sealant is an elastic sealant prepared by adding liquid silicone sealant as the base polymer and adding curing agents and additives. It has excellent weather resistance and aging resistance. According to the packaging form, it is divided into one-component silicone sealant and two-component silicone sealant. Divided into silicone structural sealant and silicone sealant by application. Silicone structural sealant is mainly used for the structural assembly of curtain walls and sealing of hidden frames, semi-hidden frames, and point-supported glass curtain wall insulating glass; silicone sealant is mainly used for sealing of framed insulating glass, such as insulating glass for doors, windows, and exposed frame curtain wall.

Which is better, polysulfide sealant or silicone sealant for insulating glass?

Polysulfide sealant and silicone sealant have their advantages and disadvantages. The advantages of polysulfide sealant are good air tightness, excellent oil resistance, solvent resistance, and water resistance; the disadvantage is poor UV resistance. The advantage of silicone sealant is that it has high strength and excellent weather resistance and aging resistance; the disadvantage is that it has a high water vapor transmission rate and poor oil resistance. When selecting the sealant, it should be selected according to the location where the sealant is used and the characteristics of the material. If used for structural assembly of curtain wall and a insulating glass of the hidden frame, semi-hidden frame, and point-supported glass curtain wall, silicone structural sealant must be selected; framed insulating glass (such as doors and windows, exposed frame glass curtain wall, etc.) should use polysulfide sealant and silicone sealant can also be used.