Why we recommend you choose LIJIANG Glass TPS Automatic Sealing Robot Line?

TPS/4SG glass warm edge sealing system: Why we recommend you choose LIJIANG Glass TPS Automatic Sealing Robot Line

1. Introduction to TPS

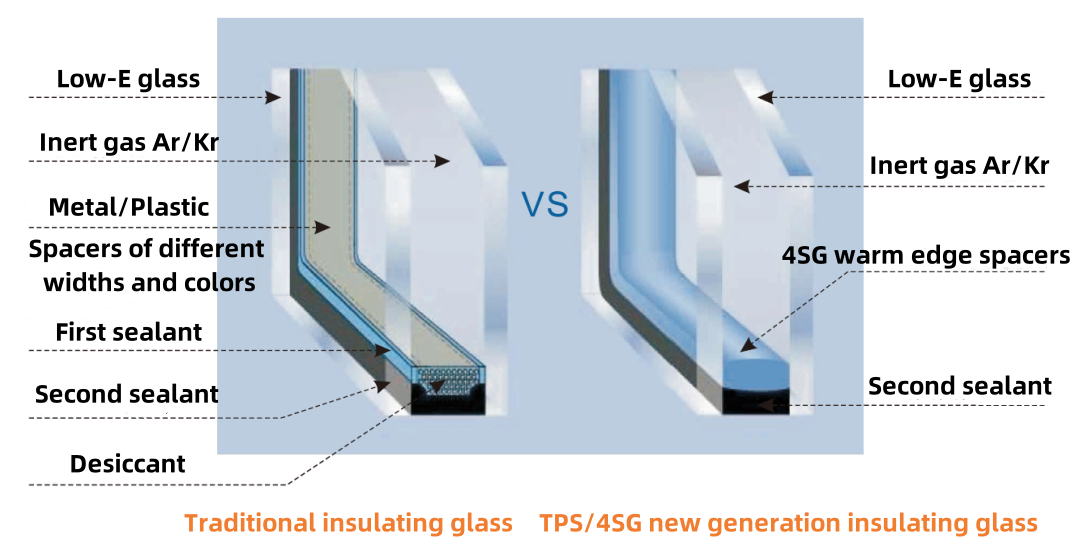

TPS is the abbreviation of THERMO PLASTIC SPACER, which can be translated into thermoplastic spacer. TPS is a new type of insulating glass warm edge system, which is a thermoplastic spacer filled with molecular sieves with special butyl adhesive as auxiliary material. It can perfectly replace the traditional hollow aluminum strip, as shown in the figure.

Figure 1 The comparison between traditional insulating glass and TPS insulating glass

Figure 1 The comparison between traditional insulating glass and TPS insulating glass

2. Introduction to 4SG

If TPS is the first-generation product, then 4SG is the second-generation upgraded product. The difference is that TPS can only be used with polysulfide adhesive, which is suitable for glass structures or curtain walls such as open-frame doors and windows. 4SG polysulfide adhesive and structural adhesive can be used universally; chemical bonds are formed between glass and 4SG, and between the outer silicone structural adhesive and 4SG. Therefore, the structure and bonding performance is stronger, avoiding the problem of creep of the spacer strip caused by long-term aging of the curtain wall glass under the action of the atmosphere and long-term tearing or squeezing of the sealing system under the action of glass pumping. The inherent Shore hardness support characteristics of the external sealant ensure that the curtain wall glass has a longer life and more stable performance. 4SG is used in conjunction with structural adhesive and is applied to curtain wall insulating glass.

3. Advantages of TPS products

(1) TPS thermoplastic spacers do not contain metal inserts, which improves the heat barrier of the glass edge;

(2) It has a more uniform surface temperature distribution on the inner and outer surfaces of the glass, effectively reducing the generation of condensation;

(3) Elastic edge sealing makes glass design more flexible and convenient, perfectly matching the glass assembly industry;

(4) High-quality control and longer effective life;

(5) The second sealant can be silicone or polysulfide.

4. Support force of TPS thermoplastic spacers

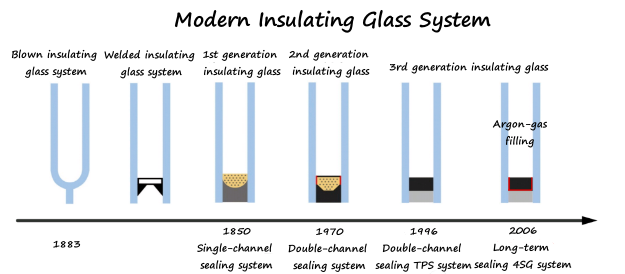

From the historical development of insulating glass, it has successively experienced blown insulating glass, welded insulating glass, and bonded insulating glass.

Figure 2 The evolution of insulating glass

Figure 2 The evolution of insulating glass

The main function of the aluminum strip insulating glass (bonded insulating glass) is to evenly separate the two pieces of glass without bearing any force. Insulating glass is installed vertically, and the aluminum strip does not bear the weight of the glass. Moreover, the sealing butyl adhesive coated between the hollow aluminum strip and the glass is a hot-melt adhesive, which remains soft and plastic throughout the glass life cycle and maintains good sealing performance. If subjected to long-term strong extrusion, a sealing butyl adhesive will lose its sealing performance after extrusion. The special plastic butyl strip of TPS can evenly separate the two pieces of glass and maintain the hollow sealing performance, while also withstanding long-term strong extrusion without losing its sealing performance.

5. Mechanism of TPS to improve the thermal insulation of glass edges

TPS thermoplastic strips use special butyl strips to replace aluminum strips and obtain a thermal conductivity coefficient Ψ far lower than that of aluminum strips, thereby reducing the thermal conductivity efficiency of windows and improving the thermal insulation of glass edges. See the table for the comparative calculation of thermal conductivity efficiency between TPS windows and aluminum strip windows.

Table 1 Thermal conductivity efficiency of windows

Thermal conductivity of windows | ||

| Window frame | Uf=1.54W/m2k | |

| Ψ | 0.08W/mk | 0.108W/mk |

| Glass | Ug=1.15W/m2k | |

| Glass width | 1.23m(4.03ft) | |

| Glass height | 1.48m(4.9ft) | |

| Frame width | 0.12(4.9ft) | |

Calculated Uw Uw=1.51W/m2k (TPS)Uw=1.69W/m2k (Aluminum) | ||

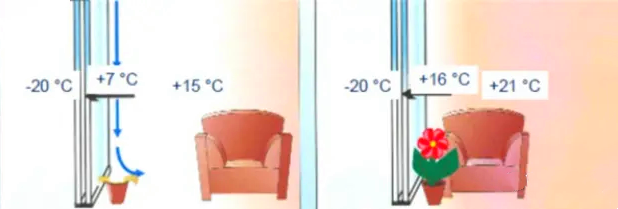

6. The practical significance of TPS improving the thermal insulation of glass edges

It is well known that the air temperature near the indoor surface of aluminum strip windows in winter is much lower than room temperature. TPS has better thermal insulation than aluminum strip windows, which can significantly increase the air temperature near the window and reduce the indoor temperature difference. It has the advantages of stabilizing the indoor climate, reducing air convection, more comfortable indoor environment, reducing condensation on the edge of the glass, inhibiting the formation of mold, reducing the maintenance cost of window frames, lower mold stress, reducing heat loss in the house, and reducing energy consumption.

Figure 3 Advantages of applying TPS

Figure 3 Advantages of applying TPS

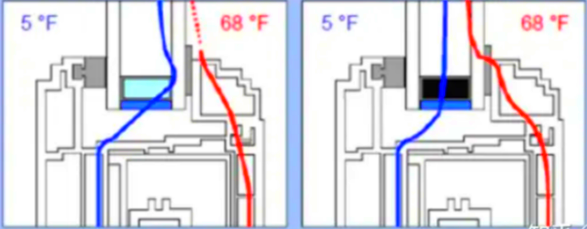

Figure 4 The isothermal curve: Aluminum Strips VS TPS Warm Strips

Figure 4 The isothermal curve: Aluminum Strips VS TPS Warm Strips

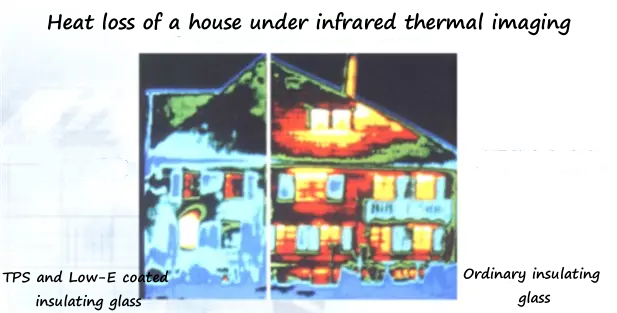

Figure 5 The house heat loss under infrared thermal imaging

Figure 5 The house heat loss under infrared thermal imaging

For example: the U value of ordinary non-inflated insulating glass is 3.0W/m2·K, and the U value of TPS inflated insulating glass is 1.2W/m2·K. 20,000m2 of glass area can save 420,000L of fuel kerosene consumption and reduce 1,095,000Kg of carbon dioxide emissions in one year.

7. Reasons for the excellent performance of TPS

7.1 Production of TPS insulating glass

From Low-E glass edge film removal, sheet loading, pure water washing, drying, insulated sheet assembly, and sealant coating, the process is completed in one go using a fully automatic production line, eliminating the mistakes caused by manual production.

7.2 Continuous high quality

TPS insulating glass system has passed many global certifications: JISR320, NFP78-451, NFP78-452, UNI10593, EN3567, EN1279-2, EN1279-3, STME773, STME744, SFS4704, DIN1286/1, DIN1286/2, AN2-12.8M, etc.

7.3 Super long service life

Once the air layer of insulating glass invades water vapor, it will become ineffective. TPS's excellent shielding of water vapor gives it a super long service life that exceeds that of the aluminum strip system.

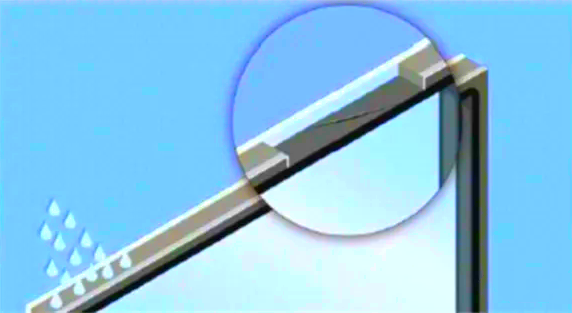

7.4 Coating connection design

TPS patented slope edge sealing technology

Figure 6 The slope edge sealing technology

Figure 6 The slope edge sealing technology

Compared with the flat interface of aluminum strips, the connection at the interface is tighter, the sealing performance is better, and the service life is longer.

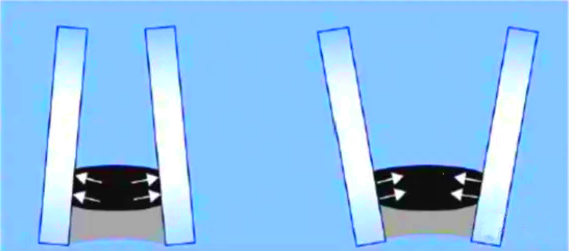

7.5 Good edge sealing performance, anti-resonance, and sound insulation

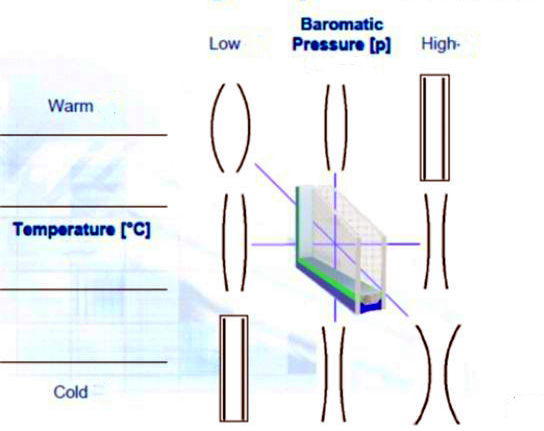

TPS's good mechanical properties and peel strength ensure the edge sealing performance under positive and negative pressure. The elasticity of TPS thermoplastic spacers ensures that it can be used for frequent changes in external temperature and wind pressure, and has good anti-resonance and sound insulation, as shown in the figure.

Figure 7 The pump suction effect of TPS insulating glass units

Figure 7 The pump suction effect of TPS insulating glass units

Figure 8 The stress of glass plate

8. TPS is far superior to an aluminum strip system in terms of moisture permeability and gas leakage rate.

The factors that cause moisture permeability and gas leakage of insulating glass include:

(1) In the insulating glass system, a sealant (butyl extruder coating) is used for sealing. Taking the three-glass two-chamber insulating glass system as an example, the sealant of the traditional aluminum strip window has 8 interfaces, while the TPS system has only 4 interfaces, which is half the number of interfaces; and TPS is produced by fully automatic machines, which avoids the errors of workers' operation and brings lower stress relaxation.

(2) High moisture permeability and gas leakage caused by excessive corner pressing

Figure 9 Leakage caused by excessive corner pressing

Figure 9 Leakage caused by excessive corner pressing

(3) Local excessive tension of edge seal caused by misalignment

Figure 10 Local excessive tension of edge seal caused by misalignment

Figure 10 Local excessive tension of edge seal caused by misalignment

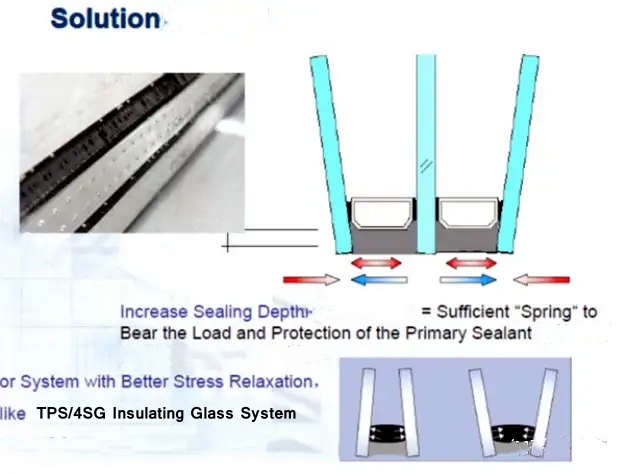

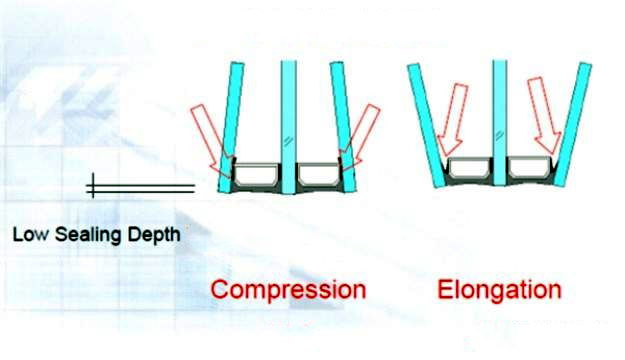

(4) Excessive tension of the sealant that plays a sealing role will also cause the shrinkage of the sealant, reduce the contact area, and reduce the sealing performance.

Solutions: (1) Increase the thickness of the sealant layer; (2) Sufficient "elasticity" to withstand the load and protect the sealant layer; (3) Sealing system with better stress relief performance, such as TPS system.

Figure 11 The Lower sealing depth of single-channel sealant insulating glass

Figure 11 The Lower sealing depth of single-channel sealant insulating glass

Figure 12 Solution: Adopts the TPS/4SG insulating glass system

9. TPS- The most flexible process for insulating glass manufacturing at present

To free you from the inefficient production of manually sealed insulating glass units, LIJIANG Glass has brought a new solution. With the TPS fully automatic sealing robot line, we can upgrade the LIJIANG Glass insulating glass production line with spacer bending, filling, and coating from an entry-level configuration to a fully automatic production line. The main advantage of the new TPS automatic sealing robot line is the reliable gear pump precision sealant dispensing technology, which ensures extremely high glue dispensing accuracy. This flow-controlled glue dispensing function can accurately measure the sealant depth and spacer width of the sealant and then apply the required amount of sealant.

Figure 13 LIJIANG Glass TPS/4SG Insulating Glass Sealing Robot Line

Figure 13 LIJIANG Glass TPS/4SG Insulating Glass Sealing Robot Line

The TPS fully automatic sealer is not only a piece of equipment, but also a manifestation of the glass deep processing technology that strives for excellence. It is a system solution for efficient insulating glass manufacturing.

The time-consuming and complex processing problems common in insulating glass production are greatly simplified by directly coating the thermoplastic spacer material on the glass surface. There is no need to stock a variety of different spacer frames or joints. During the coating process, you can change the width of the side spacer at any time according to your needs without stopping to adjust.

It can be said that TPS is the most flexible way to produce insulating glass, multi-cavity insulating glass, or solar glass components today, without a doubt.

Know More