LJBZ3370 Automatic Jumbo Size Double Gas Filling Insulating Glass Production Line

LIJIANG Glass LJBZ3370 Automatic Jumbo Size Double Gas Filling Insulating Glass Production Line could produce large-format insulating glass with a maximum length of 3300mm and a maximum height of 7000mm. It is suitable for the production of lengthened and increased curtain wall insulating glass...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJBZ3370 Automatic Jumbo Size Double Argon-gas Filling Insulating Glass Production Line

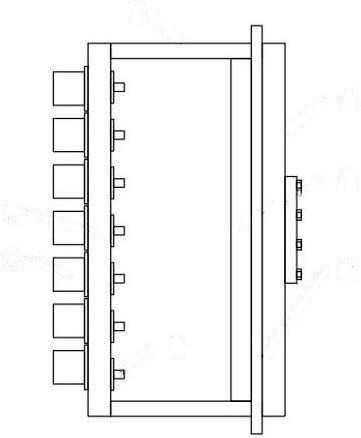

Figure 1 LJBZ3370 Automatic Jumbo Size Double Argon-gas Filling Insulating Glass Production Line

Figure 1 LJBZ3370 Automatic Jumbo Size Double Argon-gas Filling Insulating Glass Production Line

Video 1 The upper frame segment of jumbo size automatic insulating glass production line

Video 2 The sealing segment of jumbo size automatic insulating glass production line

Video 3 The lifting segment of jumbo size automatic insulating glass production line

Equipment Performance

- Germany Siemens PLC control system, touch screen interface

- Automatic identification of coated and Low-E glass

- 3 pairs of soft brushes can wash online and offline Low-E glass

- The washing machine adopts SS material and waterproof device

- Water tank with automatic temperature control and water washing system

- Air heating system

- Air Fan automatic start and stop setting

- Noise reduction system

- Online display of washing speed

- Intelligent intermittent work, saving energy

- Adjustable pressing board to keep the plate pressing surface straight

- Connection mode of aviation plug

- Applicable to produce triple insulating glass and shaped insulating glass.

Figure 2 LJBZ3370 Automatic Jumbo Size Double Argon-gas Filling Insulating Glass Production Line

Figure 2 LJBZ3370 Automatic Jumbo Size Double Argon-gas Filling Insulating Glass Production Line

Option Function

- Pre-washing

- Automatically accurate positioning for 3 or 4 side step IG

- Automatic Gas filling can set gas value and display the process of filling online with high gas concentration.

Figure 3 The lifting table: used for the upper frame section

Figure 3 The lifting table: used for the upper frame section

The Function of Insulating Glass Filled with Argon-gas

- Improve thermal insulation performance. Because inert gases have higher density and lower thermal conductivity than air, their performance is more stable. Therefore, it can slow down the heat convection in the middle layer and reduce the thermal conductivity of the gas. It can be seen that the higher the argon concentration, the better the insulation performance.

- Argon gas can bring the inner surface of the glass closer to room temperature, reducing the occurrence of condensation and making it less likely to cause condensation and frost in winter.

- Improve the safety of glass. The window glass area of modern buildings is large. If the hollow layer is uneven, the two layers of glass will be unevenly stressed under the action of atmospheric pressure and internal suction will occur. After filling with argon gas, the pressure difference between the inside and outside can be reduced, the pressure balance can be maintained, and the glass bursting caused by the pressure difference can be reduced.

- Argon is an inert gas that can effectively reduce resonance and greatly improve its sound insulation and noise reduction effect.

- Because the gas-filled is a dry inert gas, the air containing moisture in the insulating glass cavity can be replaced to keep the environment in the cavity dry and extend the service life of the molecular sieve in the aluminum spacer frame.

- When using low-emissivity Low-E glass or coated glass, since the filled gas is an inactive inert gas, it can protect the film layer, reduce the oxidation rate, and extend the service life of the glass.

Operation Steps

- Put the glass into the feeding section of the glass washing and drying machine, push the glass into the washing section by hand, and the glass will be washed and dried in the discharging section;

- Check the glass washng and drying quality in the discharging section;

- When the glass enters the laminating machine and reaches the end point close to the switch, the glass automatically stops at the positioning column;

- There is a foot switch at the end of the lamination machine. Step on the foot switch and the aluminum frame will be positioned and moved out. Position the glued aluminum frame and place it. Step on the foot switch again and the aluminum frame will be positioned and retracted;

- At the same time as the above step, after the second piece of glass has been cleaned and dried, it automatically stopped at the proximity switch at the end of the discharging section of the cleaning machine for use;

- Manually move the second piece of glass to the laminating machine and combine it with the first piece of glass;

- Press the start button of the roller laminating machine, and the laminated glass will automatically enter the roller laminating machine. After being rolled, the glass will reach the predetermined thickness size;

- The closed pieces of glass enter the turning table and automatically stop at the end of the turning table. Press foot switch 2 to release the flat material from the table.

Figure 4 The adjustable light brightness function of the aluminum frame installation section 1

Figure 4 The adjustable light brightness function of the aluminum frame installation section 1

Figure 5 The adjustable light brightness function of the aluminum frame installation section 2

Figure 5 The adjustable light brightness function of the aluminum frame installation section 2

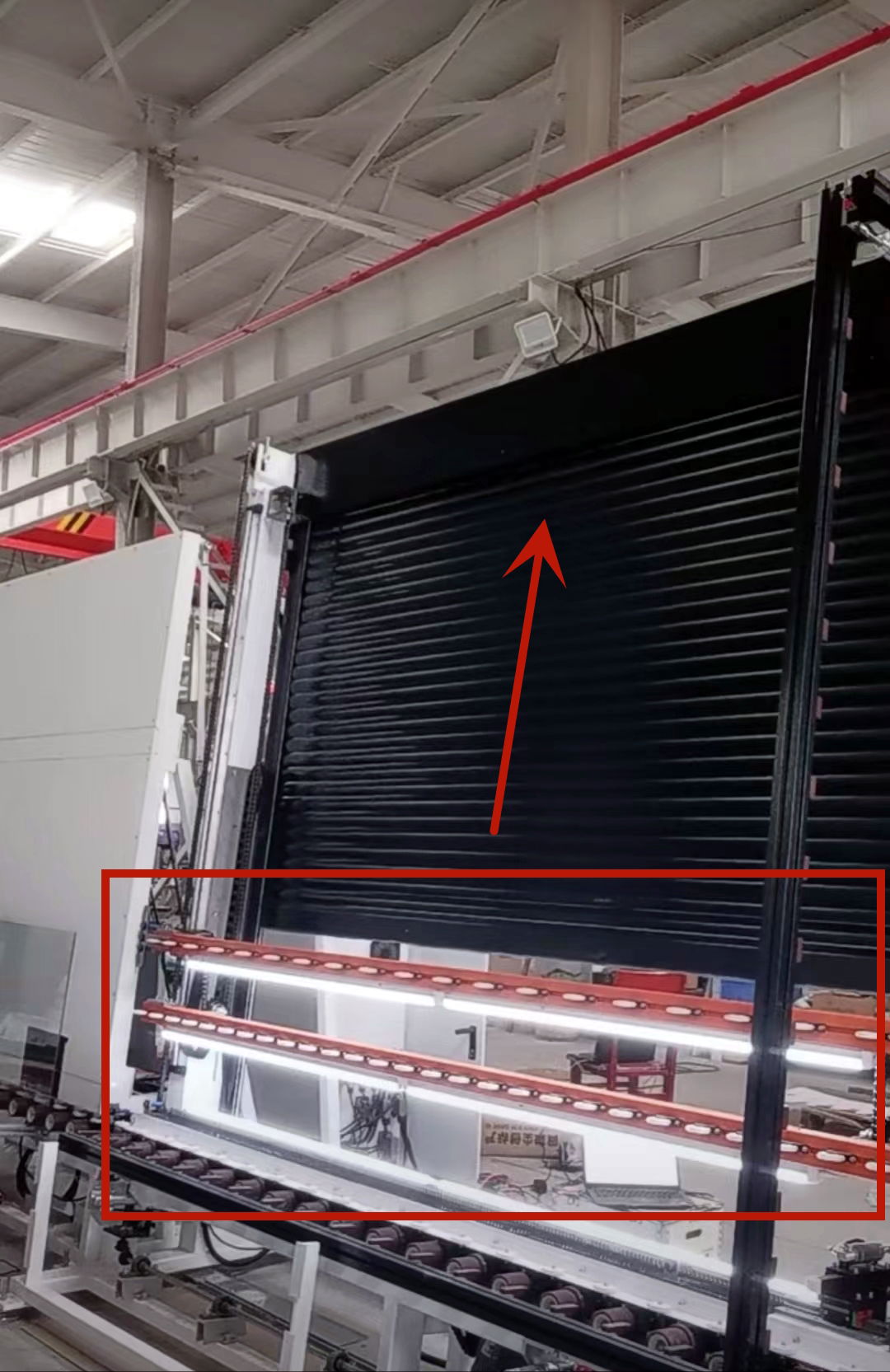

Figure 6 Adopts a movable roller shutter on the aluminum spacer frame installation section 1

Figure 6 Adopts a movable roller shutter on the aluminum spacer frame installation section 1

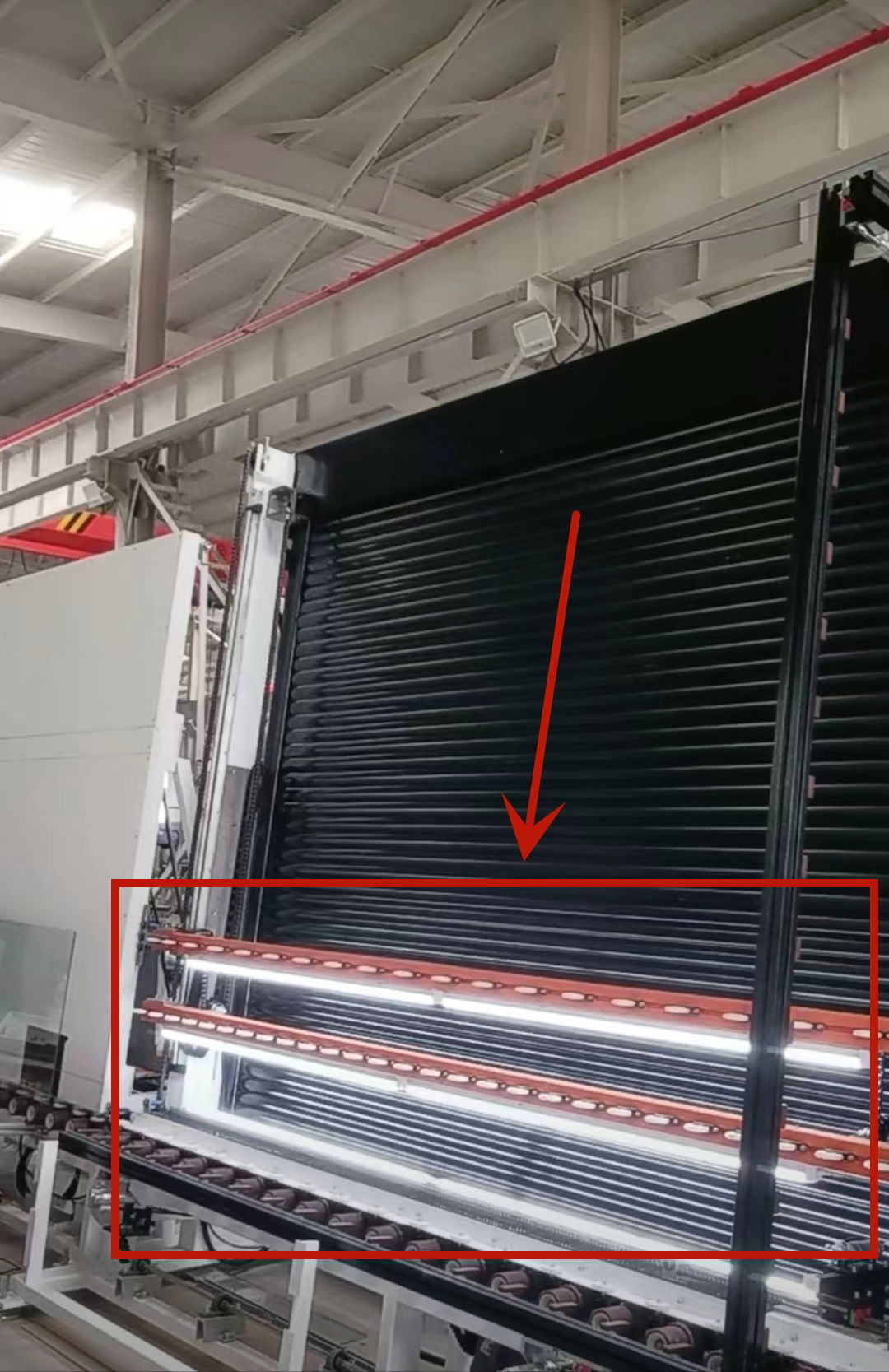

Figure 7 Adopts a movable roller shutter on the aluminum spacer frame installation section 2

Figure 7 Adopts a movable roller shutter on the aluminum spacer frame installation section 2

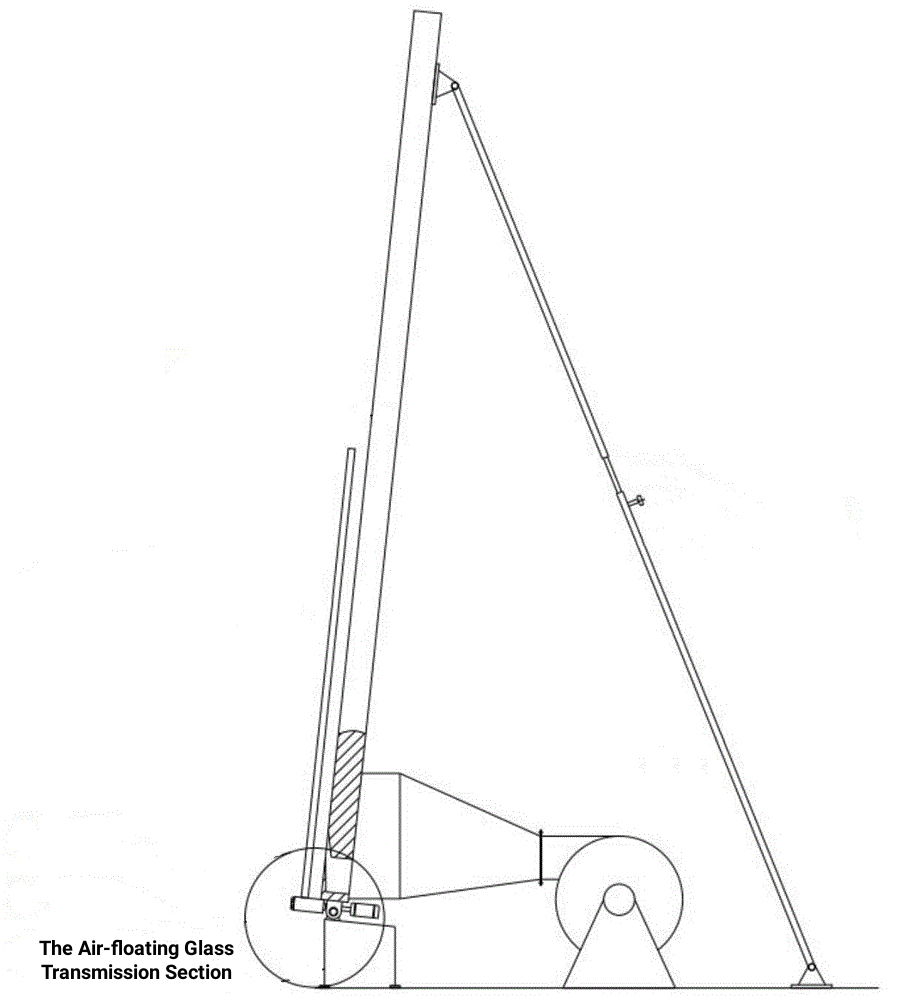

The Air-floating Glass Transmission Section

At present, with the development of technology and market demand, the insulating glass format of glass curtain wall buildings continues to expand and its thickness continues to become thinner. Therefore, the production technology of the automatic insulating glass production line is required to be higher. At present, large-sized flat glass is mostly transported by contact transmission rollers. These contact methods can easily cause scratches and contamination to the flat glass, and can easily cause the glass to break, thus seriously affecting the quality of the product and thus the production efficiency.

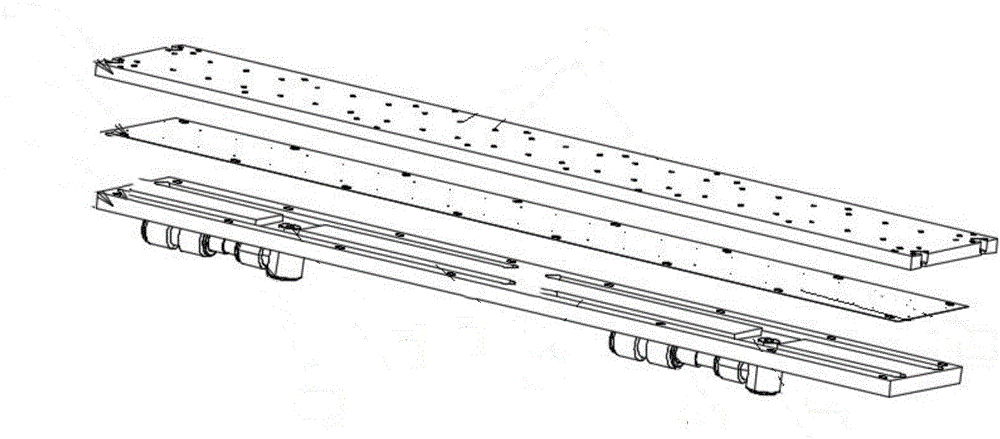

Figure 8 The Air-floating Glass Transmission Section 1

Figure 8 The Air-floating Glass Transmission Section 1

Based on the phenomena of scratches and contamination that often occur among glass deep processing practitioners, LIJIANG Glass independently developed and produced an air-floating glass transmission section, which is used for air-floating transportation of large-scale glass, including a bracket and an air-floating transportation platform installed on the bracket. , the air flotation conveying platform is assembled and spliced by several air flotation conveying plates; several floating holes are distributed on the air flotation conveying plate, and a conveying channel is opened inside the air flotation conveying plate, and the conveying channel runs through the side of the air flotation conveying plate, Each of the floating holes is connected to a transportation channel inside the air flotation transport platform; the floating holes are in the shape of a funnel with an upward opening, and diversion grooves are evenly provided around the edges. The new air-floating glass transmission section has a simple structure, easy processing, and flexible operation. Through airflow control, specific airflow distribution can be achieved to achieve air-floating lifting with uniform lifting force, stable load-bearing of large glass, and convenient transportation.

Figure 9 The Air-floating Glass Transmission Section 2

Figure 9 The Air-floating Glass Transmission Section 2

The External Plate Pressing Structure Section

Most of the insulating glass plate pressing structures currently in use use ball screws and hydraulic pressure. In the actual production process, most of the production line equipment and transportation structures require the insulating glass to be transported at an angle, resulting in subsequent plate pressing. The structure is also tilted. After long-term use, the plate-pressed structure is prone to metal fatigue, causing the insulating glass to collide with the plate-pressed structure, causing fragmentation and delaying production progress. Secondly, during the subsequent plate pressing process, the hydraulic pressure The mechanism and ball screw are easily prone to stroke deviation, resulting in uneven subsequent plate pressure, which may lead to loose sealing or fragmentation.

In response to this problem, LIJIANG Glass independently developed and produced an automated insulating glass outer sheet pressing production line using a plate pressing device. Through storage boxes, buffer rods, buffer springs, mounting blocks, balls, and negative pressure suction cups, it can ensure During the process of extrusion and transportation, the insulating glass is in a relatively stable state and will not be dislocated, which avoids the problem of loose sealing and improves the quality stability of the product. Through the limiting frame, limiting rollers, plate surface, and base, The working stroke of the limiting plate can be limited to avoid the problem of uneven force, which may lead to broken insulating glass or loose sealing.

Figure 10 The External Plate Pressing Structure Section 1

Figure 10 The External Plate Pressing Structure Section 1

Video 4 The inflatable section display: naturally inflated from bottom to top

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

How is the drying section of the insulating glass production line driven? What are the advantages?

What method is used for Low-E Glass coating detection in the feeding section?

How many pieces of glass can be parked at the same time in the third section?

How to adjust the glue depth for the upper frame section of the aluminum frame?

Section 5 needs to measure the thickness of glass and aluminum frame, what is its main function?

What is the structure of the inflatable beam and the conveyor belt in the pressure section of the inflatable plate,

The inflatable beam and the conveyor belt in the pressure section of the LIJIANG Glass inflatable plate adopt an integrated synchronous belt structure. This method has better sealing performance, and the insulating glass is not easy to leak during the process of inflating and assembling; other manufacturers use a separate structure for the transmission wheel and the inflating beam. In this way, the bottom is prone to air leakage during the inflating and closing process.