2023 brand list of the door, window, and curtain wall supporting materials-fireproof glass.

For buildings, especially for glass curtain wall buildings, fire is one of the greatest disasters that threatens property and personal safety. It can easily cause dozens or hundreds of casualties and hundreds of billions of property losses... All sectors of society are always looking for ways to reduce fire hazards, a method of protecting safety, fireproof glass emerged at the historic moment.

The emergence of fire-resistant glass has become the "guardian" of personal safety and property protection. It can insulate and be flame-retardant, allowing people in fires to have sufficient time to escape. It is the "safety guard" of building doors, windows, and curtain wall projects.

Fireproof glass has both good light transmittance and fireproof performance. It is mainly used in fireproof separation openings of buildings, atriums, etc. It can also be used in local firewall openings. According to the structure, it can be divided into composite fire-resistant glass and single-piece fire-resistant glass; at the same time, according to its fire-resistant performance, it can be divided into insulating type (Class A) fire-resistant glass and non-insulating type (Class C) fire-resistant glass; in addition, according to The fire resistance limit is divided into five levels: 0.5h, 1.0h, 1.5h, 2.0h, 3.0h.

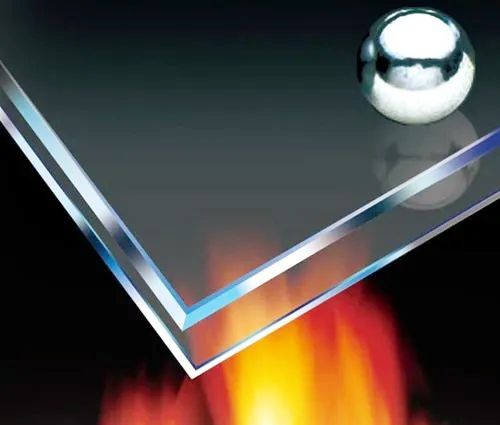

Figure 1 The door, window, and curtain wall supporting materials-fireproof glass 1

At present, the upstream and downstream industries of glass production and deep processing show a clear "polarization". TOP companies have fast technology research and development and product update iterations, brand-added value has gradually increased, digital and intelligent technology applications have become more popular, and the scale of leading companies has steadily increased.

Based on the "Industry Data Statistics Worksheet" that has been continuously carried out for many years and the "Five Elements" of company evaluation, LIJIANG Glass brings you preferred brand recommendation information for related supporting materials and service companies.

Element 1: Product quality (brand value)

In an era of high costs, product selection must be based on the actual needs of the project, and products with high-cost performance are the prerequisite for everything. Quality cannot be pursued simply through "high investment". The brand is the core spokesperson that drives a company's market share and reflects the high quality of its products.

Element 2: Scale and production capacity

Supporting materials are widely used, from engineering to home decoration, from doors, windows, curtain walls to interior decoration, etc. The potential market size is huge and there are many companies in the industry, making it impossible to make simple comparisons. Enterprise production and R&D capabilities have become an important "threshold" for brands. Reference indicators include production base distribution, overall production capacity, as well as personnel and product lines. Medium and large manufacturers with advanced production equipment and teams can outperform "small-scale" manufacturers.

Element 3: Channel Capability (Market Positioning)

There are differences in the regional characteristics of the building and the cultural characteristics of the residents. At present, the requirements for domestic projects are increasing day by day. Product positioning is based on project characteristics and needs. Channel development has become a very critical link in the market. At the same time, channels also serve as the main link between enterprises and upstream and downstream and are the lifeblood of enterprise survival.

Element 4: Intelligent productivity

The supporting materials of doors, windows, and curtain walls are the main components of the building. It is not necessarily the final component, but it must be the panel, frame, or supporting material that plays a key role. The advancement of intelligent equipment and digital production determines the market competitiveness of an enterprise. Replacing intensive labor with unmanned systems is an important indicator for improving product technology and performance standards.

Element 5: Technical service capabilities (after-sales and product structure)

Service capabilities are not only reflected in the company's supporting facilities and series but also in production equipment maintenance, transportation, feedback speed, processing plant radiation range, etc. must form a platform service. From establishing a modern data terminal to a front-end service team, we can not only obtain a product architecture that meets project needs but also achieve rapid updates and maintenance.

In the door, window, and curtain wall industry, in addition to focusing on door and window products and curtain wall systems, more attention has also been extended to the field of supporting materials. In 2023, in addition to the main glass curtain wall construction materials such as architectural glass and aluminum profiles that LIJIANG Glass pays special attention to, in fact, small materials such as fire-resistant glass and fire-resistant partitions also have a lot of knowledge.

Next, LIJIANG Glass made full use of the "five-elements" evaluation system to make detailed brand recommendations for fire-resistant glass, making the industry more interconnected and improving the brand system of the industry chain.

The panel material is one of the main elements in building curtain walls, doors, and windows. It attracts a lot of attention from architects, design institutes, and construction units, and glass is the largest "fabric". In recent years, with the improvement of fire safety levels, "fire-resistant glass" that combines beauty and practicality has attracted more and more attention.

With the new building codes and industry standards, fire protection has become a very important link in building safety design. Each area of a building is designed with a fire rating by the building codes. The glass components used in these areas must be equal to or higher than the area. The required fire protection level, therefore: fireproof glass that prevents from not "burning" came into being. Next, LIJIANG Glass uses the "5 elements" of the evaluation system to present the market's preferred high-end fireproof glass brand in 2023.

No 1. Pilkington UK

Manufacturer: Nippon Sheet Glass Co., Ltd.

Reason for recommendation: Pilkington fire-resistant glass is represented in several hundred fully tested and approved glazing systems. This includes doors and partitions of various framing materials and designs, facades and roof glazing, and more recently even the first fire-resistant sliding doors and windows.

Brand value: ★★★★☆

Scale and production capacity: ★★★★★

Channel Development: ★★★★☆

Intelligent productivity: ★★★★☆

Technical service capabilities: ★★★★☆

Recommendation index: ★★★★☆

No 2. Saint-Gobain Glass

Manufacturer: Saint-Gobain in the France

Reason for recommendation: As protection is a priority in building conception, Vetrotech Saint-Gobain provides you with high security and confidence to protect people, assets, and buildings against the combined threats of physical attack and fire. Vetrotech Saint-Gobain is a company fully specialized in the development, manufacture, and distribution of sustainable fire-resistant and fire-rated glass. Enjoy all the benefits of glass, while feeling safe and comfortable in secure living places: light, visibility, design, and transparency.

Brand value: ★★★★☆

Scale and production capacity: ★★★★

Channel development: ★★★★

Intelligent productivity: ★★★★★

Technical service capabilities: ★★★★☆

Recommendation index: ★★★★☆

No 3. Germany Schott

Manufacturer: Germany SCHOTT AG

Reason for recommendation: SCHOTT PYRAN® is one of the market leaders in fire-resistant glazing thanks to its combination of high resistance to fire, hot gases and smoke, and stylish appearance. A popular choice for airports, hotels, and shopping malls, it retains its transparency and stability, even under high thermal loads, which is vital to make evacuation quicker and safer.

Brand value: ★★★★☆

Scale and production capacity: ★★★★☆

Channel development: ★★★★

Intelligent productivity: ★★★★☆

Technical service capabilities: ★★★★☆

Recommendation index: ★★★★☆

No 4. AIS Glass

Manufacturer: Asahi India Glass Limited (AIS)

Reason for recommendation: At AIS, we believe that safety comes first, with an increase in fire outbreaks in India, it is now vital to be prepared when it comes to protecting your space and loved ones from fire. Given several recent fire incidents in India, we believe that this range of Fire-Resistant Glass products can play a pivotal role in containing the damage to life and property caused by fire. To achieve this, AIS Glass has launched a new range of Fire-Resistant Glasses.

Brand value: ★★★★☆

Scale and production capacity: ★★★★

Channel Development: ★★★★☆

Intelligent productivity: ★★★★☆

Technical service capabilities: ★★★★☆

Recommendation index: ★★★★☆

No 5. AGC Glass

Manufacturer: AGC Glass Asia Pacific Sales & General Inquiries

Reason for recommendation: It is simply impossible to imagine multiple occupancy buildings that do not use fire-resistant glass. Increasingly stringent building regulations and fire safety standards demand ever higher performance from the fire-resistant safety glass used in buildings. AGC makes living and working environments safer with Pyrobel, the widest range of fire-resistant glass on the market. Fire-resistant glass can deliver up to 180 minutes of fire resistance. The glass is tested and approved by European and international standards.

Brand value: ★★★★☆

Scale and production capacity: ★★★★★

Channel development: ★★★★

Intelligent productivity: ★★★★★

Technical service capabilities: ★★★★☆

Recommendation index: ★★★★☆

No 6. China JinJing Group

Manufacturer: Jinjing (Group) Co., Ltd.

Reason for recommendation: Jin Jing Group and the Sun, with the green hug, will be "Innocence, excellence, globalization," the core concept of the lead, the pursuit of products, goods, character to the true, to pure, intellectual excellence, Evergreen, capital, talent, market, brand, service globalization. The group regards service as the extension of the product.

Brand value: ★★★★

Scale and production capacity: ★★★★

Channel development: ★★★★

Intelligent productivity: ★★★★

Technical service capabilities: ★★★★

Recommendation index: ★★★★

No 6. China Heshan Hengbao Fire Resistant Glass

Manufacturer: Heshan Hengbao Fire Resistant Glass Factory Co. Ltd.

Reason for recommendation: Heshan Hengbao Resistant Glass Factory Co. Ltd. is located in Fumin Industrial District, Taoyuan Town, Heshan City, Guangdong Province, China. The company has an independent modern industrial factory, it's about 60,000㎡; it has various specialized technical talents; there are many large advanced production types of equipment from domestic and foreign, as well as excellent inspection devices, which leave a solid foundation for product development and production. As one of the Chinese large and professional enterprises for fire rate glass, door, and window production, the company has been evaluated as a “Chinese Top-10 Fire Rate Glass Enterprise”, and participated in revising the national fire-proof glass standard.

Brand value: ★★★

Scale and production capacity: ★★★☆

Channel development: ★★★★

Intelligent productivity: ★★★☆

Technical service capabilities: ★★★☆

Recommendation index: ★★★☆

As a kind of special glass that has been processed and treated with special techniques and can maintain its integrity and thermal insulation in specified fire resistance tests, fire-resistant glass has the functions of light transmission, fire protection (smoke isolation, fire isolation, and thermal radiation blocking), and sound insulation. , impact resistance, suitable for building decorative steel and wood fire doors, windows, glazing, partition walls, lighting roofs, smoke-proof hanging walls, see-through floors, and other building components that require both transparency and fire protection.

In developed countries, the fire-resistant glass industry developed earlier and is relatively mature. Well-known product suppliers include British Pilkington (plate glass), French Saint-Gobain, German Schott (monolithic fire-resistant glass with high borosilicate), and Japanese Asahi Glass, etc. But it's expensive.Domestic fire-resistant glass companies attach great importance to R&D and production, and their products are of high quality. Many brands such as Jinjing Glass and Hengbao Fire-resistant Glass, occupy the mainstream market of fire-resistant glass with excellent fire-resistant performance, good brand image, and high-cost performance. It has large applications all over the world and has huge development potential.

For more information about LIJIANG Glass insulated glass production line and insulated glass producing machine, please click here to learn more.