The precautions and maintenance of automatic glass edge grinding machine.

The automatic glass edging machine, which is also called the glass edge polishing machine and glass edge grinding machine, is the indispensable equipment in the glass deep processing. To improve the quality of glass production and prolong the service life of the machine, it is particularly important to use the equipment correctly and maintain the machine.

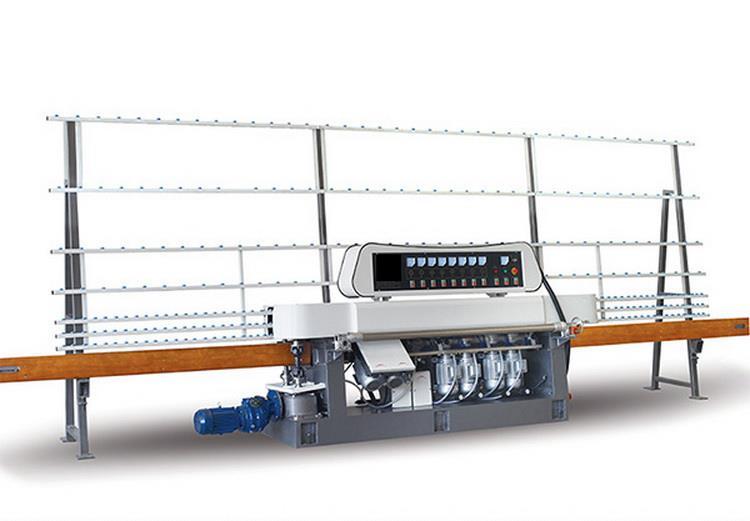

Different types of glass edging machine

The difference types of glass edge polishing machines are generally divided into straight edge edging machines, double straight edge edging machines, beveled edge edging machine, round edge edging machines, double round edge edging machines, multi-stage edging machines, and special-shaped Milling machines.

Figure 1 The difference types of glass edge polishing machines 1

Instructions for the use of a glass edging machine

1.For all kinds of newly purchased edging machines, be sure to read the instruction manual before use. After understanding the transmission principle of the machine, the functions of various handles, handwheels, electrical buttons, water and gas circuit regulating valves, and mastering the maintenance knowledge of the machine, you can operate the machine.

2.The quality of the grinding head of the edging machine has a great influence on the grinding quality of the glass. The position and moving gap of the grinding head have been adjusted before leaving the factory. When using it, except for the grinding head moving in and out, the rest should not be moved, so as not to affect the grinding quality. In addition, the back position of the grinding head should not be too large, otherwise, it is easy to damage the waterproof cover and cause water leakage, and it is easy to burn out the motor.

3.Sufficient cooling is also an important factor affecting the grinding effect. Always check the cooling pipeline for blockage. In particular, the pipeline of the linear edging machine is easy to be blocked by bristles, and it is not easy to be noticed after being blocked, which will cause insufficient cooling and affect the quality of edging.

Figure 2 Always check the cooling pipeline of the glass edge grinding machine

4. The continuously variable transmission used by the edge grinding machine must be in the open state when adjusting the speed, otherwise it is easy to damage the continuously variable transmission of the edge grinding machine.

Figure 3 The continuously variable transmission used by the glass edge grinding machine

Precautions for use of glass edging machine

1. Matters needing attention when using the linear edging machine:

The working method of a linear edge grinding machine (straight edge machine, round edge machine, and bevel edge machine) is to clamp the glass by the front and rear plate and drive its linear motion for grinding. You must pay attention to two points in use:

① The joint surfaces of the front and rear pressure plates and guide rails should be lubricated frequently, otherwise the normal service life of the machine will be affected due to premature wear of the front and rear pressure plates and the working surfaces of the guide rails. Although some models have automatic lubricating devices, it is necessary to check frequently whether the lubricating pipeline is unblocked.

Figure 4 The front and rear platens of glass edge grinding machine

② When clamping the glass, the clamping force should be appropriate. Too loose will affect the grinding quality, and too tight will increase the load on the machine, which will easily cause vibration during processing, and it is easy to pinch glass when processing thin glass. The clamping force can be tested by clamping a piece of slightly larger glass on the machine, that is, clamping the glass in the middle of the machine, pulling the glass with both hands when the machine is stopped, and feeling that the clamping force is just right when the hands cannot move it.

Figure 5 When clamping the glass, the clamping force should be appropriate.

2. Precautions when using a special-shaped glass edging machine:

①Whether the height of the suction cup of the special-shaped machine table is consistent or not has a great influence on the grinding effect. During assembly, the manufacturer has self-grinded the five sets of suction cup seats, and selected suction cup glue with the same thickness to keep the height of each suction cup consistent, so generally do not disassemble the suction cups. If the suction cup glue is damaged, choose one with the same thickness to replace it.

②After using the vacuum pump for special-shaped machines for a while, the vacuum degree (that is, the suction power) will drop due to water ingress and other reasons, so pay attention to checking and troubleshooting, otherwise, the machine will work under the condition of insufficient suction, which will affect the grinding on the one hand; on the other hand, is also prone to safety accidents.

Figure 6 The vacuum pump for glass special-shaped edge grinding machines

3. Matters needing attention when using the bilateral edging machine:

①The double-sided edging machine is a higher-grade edging machine. It is recommended to fix two or three people to operate it to ensure correct operation.

②When there is an error or fault in the program of double-sided grinding, it is recommended to ask the original manufacturer to send someone to repair and debug. Generally, do not repair it, so as not to mess up the program and cause production stoppage.

How to properly maintain the glass edging machine

1. When using the water tank to supply circulating water, replace the processed water every day to avoid the dirt in the water tank causing the water pipe to be blocked.

Figure 7 The water tank of glass straight edge machine supplies circulating water

2. When changing the water, please unplug the power plug first and then take out the water tank. After pouring out the wastewater, clean the powder scale in the water tank and the filter net.

3. After the processing operation, a large amount of foam may be generated in the water tank. Add a defoamer when replacing processing water, and spray 7 to 10 times to eliminate the generated foam. When there are too many bubbles, you can directly aim at the bubbles and spray 2 to 3 times, and the effect will be better after stirring.

4. Clean the nozzle. Once the water nozzle is blocked, the water volume will decrease or there will be no water, resulting in reduced processing capacity or even failure to work. When cleaning the water nozzle, please pull out the nozzle and use a fine needle to remove the blockage inside the nozzle.

5. Clean the waterproof cover of the edging machine. Working for a long time will cause cutting dust to adhere to the waterproof cover. If it is not cleaned in time, the cutting dust will solidify and be difficult to remove. Thus affecting the observation line of sight. After each day's processing, it needs to be cleaned with a brush and a water spray container.

6. Clean the edging room. Long-term processing will cause cutting dust to adhere to the clip shaft, chuck, and the inner wall of the edging chamber. If it is not removed in time, it will scratch the lens, and it will also wear the sealing ring of the clip shaft and cause water to enter the machine head.

There are two cleaning methods:(1) Wash directly with a brush and a water spray container.(2) Enter the machine cleaning mode to clean. This method can also clean the water supply pipeline inside the machine.

7. Clean the edging machine and the scanner shell. The machine must be cleaned immediately after daily use. Otherwise, the cutting powder will solidify on the casing and be difficult to remove. When cleaning, please use a soft cloth dampened with neutral detergent to clean the case.

8. Trimming wheel. When the grinding wheel is blunt, the processing time becomes longer, so the grinding wheel should be repaired in time.

For more information about LIJIANG Glass insulated glass production line and insulated glass producing machine, please click here to learn more.