What effect does desiccant have on the service life of insulating glass?

At present, the glass deep processing industry, especially the insulating glass industry, is booming, and the use of insulating glass molecular sieve adsorbents is also increasing year by year. Insulating glass is widely used, but the corresponding problem is that more than 80% of insulating glass on the market has a short service life, and its average lifespan does not exceed ten years. Most insulating glass will reach the end of its service life and need to be replaced in seven or eight years. With the popularity and development of insulating glass, tens of billions of funds are spent around the world every year to replace old and failed insulating glass. This huge waste will seriously hinder the development of energy-saving production and green ecology. Therefore, as the core material in the processing of insulating glass auxiliary materials, molecular sieve desiccant plays a leading influence on the service life of insulating glass.

1. The impact of desiccant on the service life of insulating glass

1.1 The impact of desiccants with different adsorption depths on insulating glass

According to many experiments by LIJIANG Glass, when the relative humidity is low, the average adsorption capacity of molecular sieves is much greater than that of silica gel and alumina, because the currently generally recognized standard for insulating glass is to test the desiccant at 25°C and a relative humidity of 10 % of the adsorption capacity in the air environment. At this time, the absolute humidity in the air is expressed as -8°C by the dew point. In other words, the evaluation standard for desiccants is to examine their ability to keep the dew point below -8°C. Taking the countries in the mid-latitudes of the northern hemisphere as an example, the standards required for desiccant are more reasonable, because the temperature is above -8°C for most of the year, and qualified insulating glass will not condense when it is above -8°C. of. Therefore, theoretically speaking, molecular sieves have a very high affinity for water molecules. Only when the relative humidity is very low will it have a significant impact on the adsorption capacity of molecular sieves. In other words, molecular sieves have a very strong ability to maintain a low dew point. , after normal insulating glass is equipped with molecular sieves, the dew point of the insulating glass cannot be measured using a general dew point tester, and the dew point cannot be measured within more than ten years of normal use.

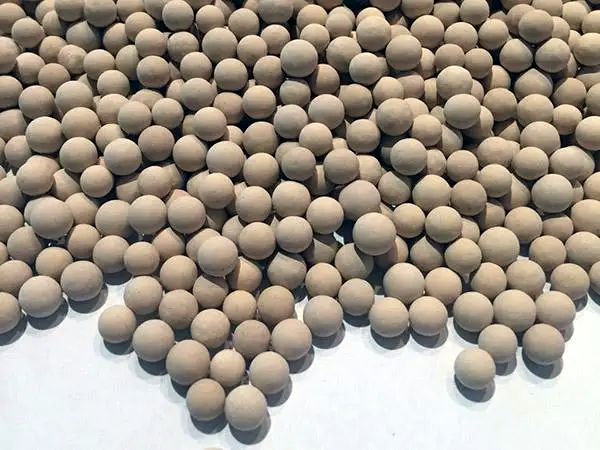

Figure 1 The insulating glass using molecular sieves desiccant

1.2 The impact of respiratory moullecar sieves on the service life of insulating glass

Since there are many types of molecular sieves, not all molecular sieves are suitable for the processing of insulating glass. Practice has proven that only type 3A molecular sieve desiccant that does not adsorb air is suitable for insulating glass. Because the molecular sieve is a network of crystalline aluminosilicates, its pore texture is very uniform, and the size of the pores is just suitable for the passage of small molecular substances. Due to different specifications and models of molecular sieves, the channel sizes are also different. For insulating glass, because it is required to absorb bed components, only water molecules can enter its pores, and other molecules of air components cannot pass through. Water molecules are 2.8 angstroms (1 micron = 10,000 angstroms) , nitrogen, oxygen, and ammonia in the air are about 4 angstroms. Currently, only type 3A molecular sieves can be used, and any other type of molecular sieve is not suitable. The pores of type 4A molecular sieves are 4.3 angstroms, so type 4A molecular sieves can absorb air. of nitrogen and oxygen.

Among the components of air, in addition to moisture, 4A molecular sieves prefer to adsorb nitrogen with greater polarity. Therefore, monitoring the intake volume of molecular sieves is mainly based on monitoring the intake volume of nitrogen. Since the current 3A molecular sieves It is derived from 4A molecular sieve through ion exchange, so 4A molecular sieve is always cheaper than 3A molecular sieve. This is why 4A molecular sieve is often used to impersonate 3A molecular sieve. As a 4A molecular sieve, its suction volume is about 7ml per gram, and the 3A molecular sieve will be less than 0.5ml per gram. The nitrogen sucked in by the 4A molecular sieve is very sensitive to small changes in temperature under normal temperature conditions. For example, 250ml of 4A molecular sieve can release more than 700ml of gas when the temperature rises from normal temperature to 70℃. The outgassing volume of 3A molecular sieve will be less than 50ml.

When processing insulating glass, we usually pack molecular sieves at room temperature. If the molecular sieve is type 4A, when the temperature decreases, the molecular sieve will adsorb a large amount of air in the hollow glass cavity, causing the pressure inside the glass to decrease; conversely, when the temperature increases, the molecular sieve will release a large amount of air that has been adsorbed inside. Increase the pressure inside the glass. After the insulating glass equipped with 4A molecular sieve is combined, due to the change of day and night and the change of seasons, the 4A molecular sieve inhales and deflates due to temperature changes. Just like breathing, the glass will continue to withstand inward and outward pressure. This sometimes inward and sometimes outward pressure greatly reduces the service life of the insulating glass, especially the hidden frame glass. The two pieces of glass completely rely on the adhesive force of the sealant, which has a considerable sealing ability from the internal air pressure. limited. Glass seals can fail at any time.

Experience shows that the service life of insulating glass using 4A molecular sieve is only one-quarter of that of 3A molecular sieve. What is even more dangerous is that if more 4A molecular sieve is used and the insulating glass is too thin or not tempered, the glass may suddenly explode and shatter. , or the whole piece of glass falls. If this kind of glass is installed on a high-rise building, it is very likely that a serious casualty accident will occur, and the consequences will be very terrible.

2. Influence of the indicators of molecular sieve insulating glass desiccant on the service life of insulating glass

2.1 Measurement conditions for molecular sieve adsorption capacity and its impact on the life of insulating glass

The adsorption capacity of insulating glass desiccant should be based on the adsorption capacity when the relative humidity is 10%. The adsorption capacity when the relative humidity is high cannot be used as a standard to detect the dew point control ability of the desiccant, so only the desiccant when the relative humidity is 10% The adsorption capacity can reflect how many years the molecular sieve can guarantee the service life of the insulating glass. Some desiccant instructions only mention the adsorption capacity and do not mention the test conditions, which is actually meaningless. For example, compared with molecular sieves, silica gel has lower deep adsorption capacity, but its shallow adsorption capacity is very large. For example, C-type silica gel can adsorb 3 times its own weight at 30C with a relative humidity of 90%, which is higher than molecular sieves under the same conditions. Incomparable. But what does such a high adsorption capacity mean for insulating glass? Because once the temperature drops a little under such conditions, the insulating glass will be filled with water vapor, so the adsorption capacity at a relative humidity of 10% is the core indicator that needs to be measured for the life of the insulating glass. The adsorption capacity at other high relative humidity cannot Measure the dew point control ability of the desiccant in the dry environment of the insulating glass cavity.

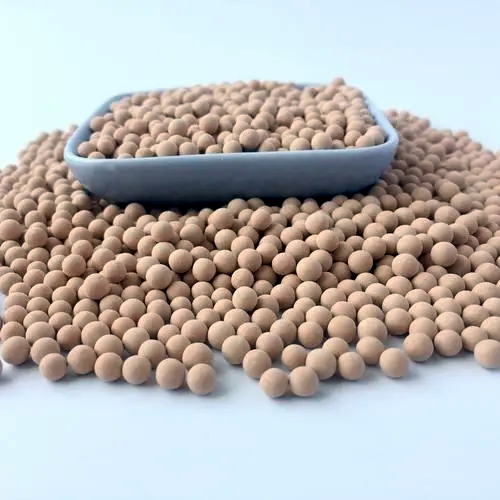

Figure 1 The measurement conditions for Insulating glass molecular sieve adsorption capacity

2.2 The meaning and practical significance of loss on ignition

The focus of the desiccant's loss on ignition is to control the initial water content of the desiccant, while also ensuring the relative inertness of the desiccant. If the initial water content of the desiccant is too high, it means that the desiccant may have excessively absorbed water. At this time, the desiccant The dew point control ability is greatly reduced, and the initial dew point of the insulating glass filled with this desiccant will also rise, which will correspondingly reduce the service life of the insulating glass; in addition, too high ignition loss may be another problem, that is, the The desiccant may contain chlorides or easily decomposed inorganic substances, such as nitrites, acids or alkali substances, or unstable organic substances, so the loss on ignition is too high and it is suspected of containing unstable chemicals. Such substances have corrosive effects and seriously affect the service life of insulating glass.

2.3 The meaning and test method of temperature rise

Temperature rise refers to the change in temperature increase after the desiccant absorbs water. Molecular sieve products go through packaging, transportation, storage and other cycles from leaving the factory to being used. If there is a problem in a certain link and the molecular sieve is exposed to the air, it will quickly absorb moisture in the air, causing product failure. Therefore, the temperature rise can be used to detect product failure quickly, simply and effectively before use. Temperature rise is an important characteristic of molecular sieves, but it is not a unique characteristic of molecular sieves. If the temperature of a desiccant rises, it may be a molecular sieve, calcium chloride, calcium oxide or a strong acid or alkali desiccant. In this way, you can test whether its aqueous solution is corrosive. Even if we exclude other corrosive desiccants, we still cannot distinguish between 3A molecular sieve and 4A molecular sieve. Therefore, we must have an instrument to test the gas desorption capacity to test the 3A or 4A type molecular sieve before we can make a final conclusion. Therefore, it is of little practical significance to use the temperature rise method alone to judge the quality of insulating glass desiccant. The desiccant must be judged by testing the PH and irritation characteristics (corrosiveness) of the aqueous solution and the gas desorption amount of the desiccant. On the premise that it is not corrosive and the gas desorption capacity is qualified, the higher the temperature rise, the better the quality of the desiccant, and the longer it can ensure the dew point life of the insulating glass.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.