The significant difference in the service life of insulating glass assembled with silicone and polysulfide sealants.

Abstract: The accelerated durability of insulating glass is tested through the moisture absorption quality of desiccant, quantitatively evaluates product quality, and provides the technical basis for service life prediction. The accelerated durability verification test results of 40 enterprise samples show that the probability of the overall moisture permeability index being lower than 0.20 is 62%, among which the moisture permeability index of silicone sealing samples is 48%, polysulfide type is 86%, and the outer sealant The type has a significant impact on the durability of insulating glass.

Keywords: insulating glass, sealing, durability, test method, silicone, polysulfide, sealant

1. The introduction

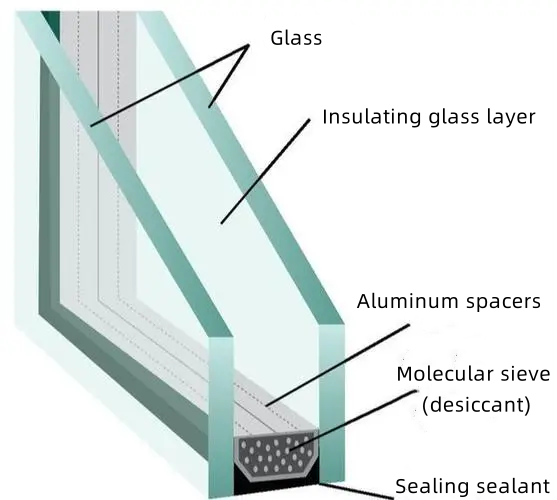

Architectural insulating glass is a unit component that is sealed and bonded around the perimeter of the spaced glass. It is bonded with sealants to form two internal and external sealing layers that block moisture. The infiltrated moisture is absorbed by the desiccant in the spacer frame, and the gas in the cavity continues. Drying is the basis of the thermal insulation function. See Figure 1 for the adhesive structure and penetration path. The desiccant absorbs the water vapor that penetrates through the sealing layer, and its mass continues to increase until it is saturated with moisture, which is characterized by condensation and condensation on the insulating glass, which means the functional life of the product has ended. Based on the size of the moisture-permeable channel, the permeability of the sealant, and the moisture absorption capacity of the desiccant, it is theoretically estimated that the service life of the insulating glass should be more than 30 years. However, the difference is far from that in actual applications. In some construction projects, condensation appears on the insulating glass after only a few years of delivery. Mainly The factors are improper product design, material selection, and operation process or incorrect installation, erosion by environmental water, water vapor, ultraviolet radiation, and chemical media, and air pressure differences caused by wind load, atmospheric pressure, and temperature changes. The body is repeatedly loaded and deformed cyclically, which accelerates the degradation of the sealing bonding body and deteriorates the bonding and sealing properties, causing early failure.

Tests have shown that accelerated aging tests under conditions such as ultraviolet irradiation, high and low temperatures, or high humidity can evaluate the deterioration trend of the structure and sealant. However, an effective method to evaluate the durability life should be characterized by the change in water absorption quality of the molecular sieve under use conditions. With its saturated moisture absorption period, this test method has been adopted by the International Organization for Standardization. Research shows that cyclic changes in temperature and humidity will promote moisture penetration. Especially under continuous high temperature and high humidity conditions, the gas in the cavity will expand, and the hardened high-modulus edge bonding body will produce ultra-high stress (such as an insulating glass cavity at a temperature of 58°C). The internal air pressure can reach 13kpa), which accelerates moisture penetration. Combining years of field experience and research results, the European standard EN1279 "Glass for Construction - Insulated Glass" adopts the "Test Method for Water Vapor Penetration Durability of Insulated Glass", based on the saturated water absorption rate of the desiccant, the initial moisture content and the final moisture content after the test. Calculate the moisture penetration index of insulating glass to characterize the sealing durability of the product. This method has good scientific applicability. The European Certification Guidelines for Glass Bonded Assembly Structures confirm that insulating glass that meets the EN1279 standard and obtains product quality certification will have a service life of 25 years.

Referring to European standards, it is required that after 28 days of high and low-temperature cycle testing, and then 49 days of continuous testing under high temperature and high humidity conditions of 58°C, the moisture penetration index of insulating glass shall not be greater than 0.20. The editor-in-chief National Glass Quality Supervision and Inspection Center conducted verification tests on the accelerated durability of 40 groups of samples, demonstrating the effectiveness and applicability of this method. This article focuses on the analysis of the main factors that affect the test results to find out the impact of the type of sealant on the outer layer of the insulating glass on the service life of the insulating glass.

Figure 1 Insulated glass bonding sealing structure and penetration path

2. Accelerated durability test

2.1 Test piece

There are 15 specimens in each group, prepared according to the same process conditions and materials, with a specification of 510mm×360mm, and the dew point of the specimens should be ≤-40°C.

2.2. Sample equipment

The test chamber should be able to provide two-stage test conditions:

1. High and low-temperature cycle stage: the temperature cycles from -18°C to 53°C, heating and cooling, one temperature cycle every 12 hours, the heating or cooling rate is 14°C/h, and the cycle lasts 58 times (28 days);

2. High-temperature test phase: maintain the temperature at 58°C for 7 weeks (49 days)In the two stages, when the test temperature is higher than 23°C, the relative humidity in the box should be ≥95%.

2.3. Test procedure

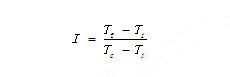

Take 4 specimens and measure the initial moisture content of the desiccant (Ti,%) after decomposition.Take 5 specimens, decompose them at the end of 77 days of test treatment, and measure the final moisture content of the desiccant (Tf,%);

Take 2 specimens, decompose and sample the desiccant, absorb water to a constant weight after saturation, and then treat it at a high temperature of 950°C or 350°C for 120 minutes to measure the standard water absorption (Tc,%), which is the saturated water absorption capacity of the desiccant of the specimen.

Accelerated durability is expressed by the moisture penetration index (I), calculated according to the following formula, taking the average of the I values of 5 specimens, and rounding to two decimal places:

3. Test results and analysis

A total of 40 groups of samples from various types of domestic enterprises were selected for the verification test, of which 20 groups of outer sealants for the two seals were polysulfide type and 19 groups of silicone type. Only one set is sealed with hot melt sealant.

3.1. Test results

The test measured the bonding width of the inner and outer seals of each group of specimens, and the test measured the moisture penetration index of each group of specimens. The test results are listed in Table 1.

Table 1 The accelerated durability test results of insulating glass

| Enterprise | External adhesive | Butyl adhesive bonding width(mm) | External bonding width (mm) | Moisture penetration index (/) |

| 1 | Polysulfide type | 3.5 | 6.5 | 0.13 |

| 2 | Polysulfide type | 4.5 | 7.5 | 0.07 |

| 3 | Polysulfide type | 3.5 | 7.5 | 0.11 |

| 4 | Polysulfide type | 3.5 | 7.0 | 0.06 |

| 5 | Silicone | 3.0 | 7.5 | 0.18 |

| 6 | Silicone | 3.0 | 6.0 | 0.36 |

| 7 | Silicone | 4.5 | 5.5 | 0.09 |

| 8 | Polysulfide type | 5.5 | 8.0 | 0.06 |

| 9 | Polysulfide type | 6.0 | 7.0 | 0.05 |

| 10 | Silicone | 5.0 | 6.5 | 0.28 |

| 11 | Silicone | 5.0 | 7.5 | 0.17 |

| 12 | Silicone | 3.0 | 7.0 | 0.31 |

| 13 | Silicone | 2.5 | 7.5 | 0.55 |

| 14 | Silicone | 3.0 | 7.5 | 0.16 |

| 15 | Silicone | 2.5 | 6.5 | 0.21 |

| 16 | Polysulfide type | 2.0 | 8 | 0.21 |

| 17 | Polysulfide type | 4.0 | 7 | 0.07 |

| 18 | Polysulfide type | 4.0 | 7.5 | 0.07 |

| 19 | Polysulfide type | 2.5 | 5.5 | 0.29 |

| 20 | Silicone | 3.0 | 5.5 | 0.20 |

| 21 | Silicone | 1.5 | 7.0 | 0.17 |

| 22 | Polysulfide type | The broken strips | 7.0 | 0.30 |

| 23 | Polysulfide type | 2.5 | 5.5 | 0.21 |

| 24 | Silicone | 3.5 | 8.0 | 0.12 |

| 25 | Silicone | 4.0 | 8.5 | 0.09 |

| 26 | Silicone | 5.5 | 8.0 | 0.14 |

| 27 | Hot melt type | -- | 9.0 | 0.10 |

| 28 | Polysulfide type | 4.5 | 8.5 | 0.06 |

| 29 | Polysulfide type | 4.5 | 8.0 | 0.11 |

| 30 | Silicone | 5.0 | 7.0 | 0.12 |

| 31 | Silicone | 3.0 | 6.5 | 0.33 |

| 32 | Silicone | 3.5 | 6.0 | 0.17 |

| 33 | Silicone | 3.0 | 7.5 | 0.14 |

| 34 | Polysulfide type | 4.0 | 7.0 | 0.07 |

| 35 | Polysulfide type | 4.5 | 8.0 | 0.11 |

| 36 | Polysulfide type | 4.0 | 7.0 | 0.06 |

| 37 | Silicone | 3.0 | 6.5 | 0.13 |

| 38 | Polysulfide type | The broken strips | 7.0 | 0.28 |

| 39 | Polysulfide type | 2.0 | 5.5 | 0.22 |

| 40 | Polysulfide type | 3.5 | 6.5 | 0.15 |

| Mean value | 3.65 | 7.06 | 0.17 | |

| Mean square deviation | 1.04 | 0.87 | 0.10 | |

3.2. Statistical analysis

3.2.1. Overall level of accelerated durability of 40 groups of samples

The samples come from 40 insulating glass companies and are representative of the technical level of domestic products. The sealant type of each group of specimens was known, and the bonding width of the outer seal of the specimens and the butyl glue bonding width were measured (Figure 1). The thickness of butyl rubber is difficult to measure, the sealant grade is unknown, and the production process level is also different. These factors will also have an impact on the test results. To evaluate the accelerated durability performance of the samples, this analysis eliminated three groups of defective samples (22#, 27#, and 38#), and used the I value as a random variable to calculate the water permeability index of the remaining 37 groups of samples according to normal distribution. The results show that the overall mean is 0.1679, the variance is 0.1044, and the maximum value is 0.55. According to the reliability level 0.05 (confidence level 95%) test, the probability of the overall I value ≤ 0.20 is 62% (shaded area in Figure 2).

3.2.2. The influence of external sealant type on I value

The outer layers of 37 groups of samples are made of polysulfide and silicone sealants respectively, including 19 groups of silicone samples. The average I value is 0.2063, the variance is 0.1116, the maximum value is 0.55, and the reliability level is 0.05. The I value is ≤0.20. The probability is 48% (Figure 3); there are 18 groups of polysulfide samples, the average I value is 0.1165, the variance is 0.0789, the maximum value is 0.29, the reliability level is 0.05, and the probability of I value ≤ 0.20 is 86% (Figure 4). Comparing Figures 3 and 4, it can be seen that the water permeability index of the two types of samples is significantly different, and the I value evaluated at the 95% confidence level is nearly doubled.

3.2.3. Effect of bonding width on I value

Increasing the bonding width improves the bearing capacity of the edge bonding and increases the length of the moisture permeability path (Figure 1), which is beneficial for reducing the moisture permeability index of insulating glass. The test results of the bonding dimensions of the test samples are basically within the range specified by the standard. According to the test results, the correlation between the bonding width of the inner and outer sealant and the I value is statistically calculated. The analysis results are as follows.

1) The relationship between the bonding width of the outer sealant and the I value

There are 19 groups of polysulfide-type samples, the average bonding width (sealing thickness) of the outer channel seal is 7.11 mm, and the variance is 0.65mm; there are 18 groups of silicone-type samples, the average bonding width (sealing thickness) is 6.95 mm, and the variance is 0.83mm. It can be seen that the bonding thickness is at a similar level. Using the bonding thickness of the sample as the independent variable to plot the I value, the linear correlation coefficients are 0.3949 and 0.0186 respectively, indicating that the bonding thickness is weakly correlated with the I value under the test conditions (Figure 5, Figure 6).

2) Influence of the bonding width of the inner sealant

There are 19 groups of polysulfide-type samples, and the average butyl glue bonding width (sealing thickness) is 3.82 mm, with a variance of 0.85mm; there are 18 groups of silicone-type samples, and the average butyl glue bonding width is 3.50 mm, with a variance of 0.84mm. It can be seen that the bonding dimensions of butyl glue are comparable. Analysis of the correlation between the I value of the sample and the bonding thickness of butyl glue shows that the I value has a downward trend with the increase of butyl glue bonding thickness under the test conditions. The correlation coefficients are 0.6540 and 0.1141 respectively, which are medium correlation and weak correlation (Figure 7, Figure 8).

4. The discussion

4.1. Silicone sealant molecules have a spiral structure, large free space, and good gas and water vapor permeability. This characteristic is widely used in gas separation and water vapor separation. Silicone sealant is a condensation room temperature vulcanized silicone rubber based on hydroxyl-terminated polydimethylsiloxane (such as HO(Me2SiO)nH). The main chain is polydimethylsiloxane, with low cross-linking density and water The vapor transmission rate is higher than that of polysulfide, polyurethane, and other basic sealants. The water vapor transmission rate of silicone sealant is about 20g/m2.d, and that of polysulfide sealant is lower than 10g/m2.d. The water permeability index of insulating glass is related to the type of exterior sealant. Under year-on-year conditions, the silicone type is nearly twice as high as the polysulfide type. This test result is closely related to the difference in moisture permeability of the base polymer.

4.2. The accelerated durability test method based on the change in water absorption quality of the desiccant is suitable for durability evaluation and product quality control of insulating glass. The German DIN 1286-1 standard uses this method to classify insulating glass products. This test principle was used to study the performance of atmospherically exposed insulating glass. The results showed that the water permeability significantly differed with the type of exterior glue during the same test conditions (Figure 7). The polysulfide type sample was exposed to the sun for 3 years, and the mass of the penetrated water was 0.35 g, 0.55g in 5 years, while the silicone type infiltrates 0.80g of water after 3 years of exposure, which is double the amount of water penetration. The results show that if the polysulfide-type outer channel sealed insulating glass has a service life of 25 years, the service life of the silicone-type product is only 10 years. The significant difference is consistent with the aforementioned test results.

5. The conclusion

5.1 Accelerated durability test is an effective method to evaluate the sealing quality of insulating glass and provides important information for evaluating service life;

5.2 Within the standard range, the bonding width has no significant impact on the water permeability of insulating glass;

5.3 The type of exterior sealant is a significant factor affecting the permeability of insulating glass. The water permeability index of insulating glass bonded with silicone sealants is much higher than that of polysulfide sealants, and the difference in durability and service life is nearly doubled.