Performance characteristics and applications of built-in blinds in insulating glass.

With the development of urbanization, energy-saving materials have been widely used. LIJIANG Glass will introduce the series of built-in sunshade products of insulating glass and details the performance characteristics and applications of built-in blinds of insulating glass.

Milan, Italy is a romantic city with a strong design atmosphere. Its design is reflected in all aspects, and architecture is no exception.

Figure 1 The glass curtain wall building located in Milan, Italy

With the development of urbanization, the improvement of design level, and the enhancement of energy-saving and environmental protection concepts, many buildings in Milan use energy-saving glass exterior walls, among which Parallelo horizontal glass office is a typical example.

Figure 2 The Parallelo horizontal glass office 1

Figure 3 The Parallelo horizontal glass office 2

When you see this building, you can't help but be shocked by its beauty, but then you will also wonder how such a building surrounded by glass can block the sun. Then what I want to talk about below is the advantage of this building's curtains placed inside the glass!

Figure 4 The sunshade curtains in the glass of Parallelo office 1

Figure 5 The sunshade curtains in the glass of Parallelo office 2

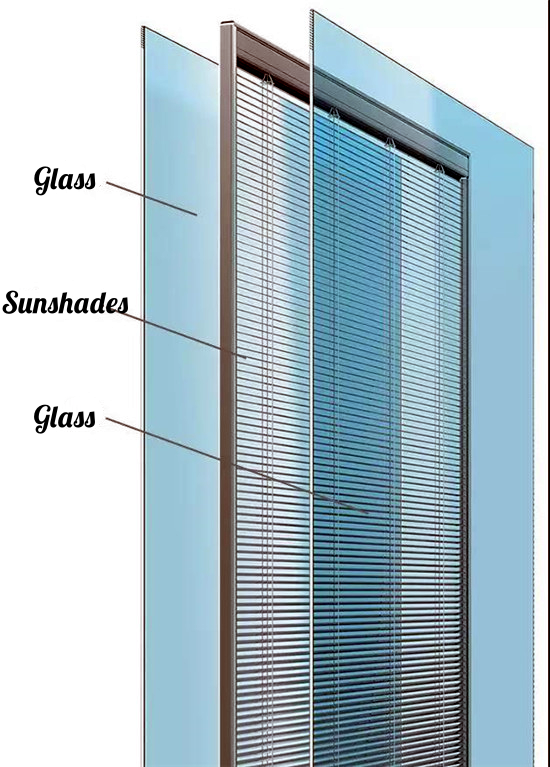

The sunshade curtains placed inside the glass mentioned here are what we often call built-in sunshade products of insulating glass. As the name suggests, its structure is to put blinds or roller blinds between two layers of glass, and a high-performance sunshade product controlled by a hand pull rod, magnetic induction, or electric remote control outside the glass.

Figure 6 The insulating glass built-in sunshade product structure diagram

Insulating glass built-in sunshade products are the crystallization of traditional sunshade products and new technologies. They have comprehensive functions of insulating glass and sunshade products, including sunshade, heat preservation, sound insulation, lighting adjustment, fire preven tion, cold resistance, privacy, space-saving, easy cleaning, etc. Not only in buildings, it has penetrated our lives:

Figure 7 The glass windows

Figure 8 The glass doors

It can be seen that the performance characteristics of insulating glass built-in sunshade products are integrated and widely used. With the application of such products in the glass curtain walls of buildings and life, the forms of sunshade products inside are also diverse. At present, the more common ones are roller blinds, pleated blinds, and Venetian blinds.

Figure 9 The roller blinds, pleated blinds, and venetian blinds of insulating glass built-in sunshade products

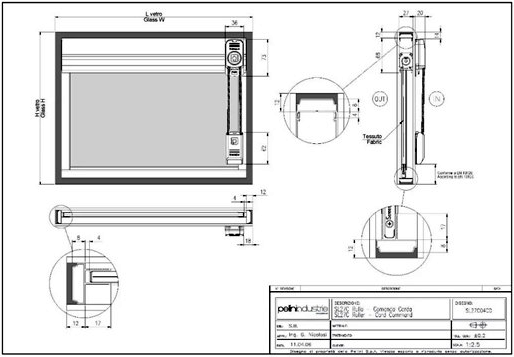

1. Built-in roller blinds insulating glass

Roller blinds seem simple, but their strength should not be underestimated. Built-in roller blind insulating glass can filter dazzling strong light and turn it into soft diffuse reflection, which can improve people's visual comfort. However, the adjustability of light is relatively simple when used.

Figure 10 The schematic diagram of the structure of the built-in roller blinds and insulating glass 1

Figure 11 The schematic diagram of the structure of the built-in roller blinds and insulating glass 2

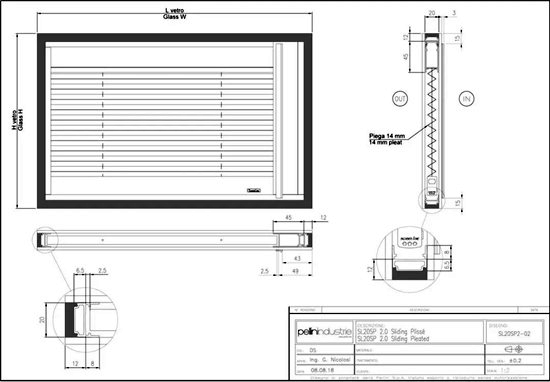

2. Built-in pleated blinds and insulating glass

The UV protection and heat insulation functions of the pleated blinds effectively protect household items. By adjusting the opening and closing positions, various light transmission effects can be met, but the flexibility is not strong.

Figure 12 The schematic diagram of the structure of the built-in pleated blinds and insulating glass 1

Figure 13 The schematic diagram of the structure of the built-in pleated blinds and insulating glass 2

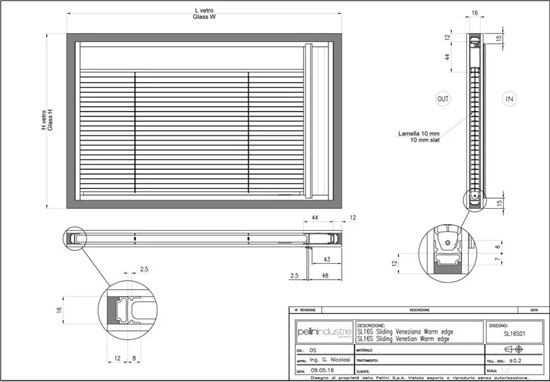

3. Built-in Venetian blinds and insulating glass

The Venetian blinds can control the incoming light through the angle of the curtain pieces. The angle of the curtain pieces can be adjusted to the appropriate position according to the light, and the flexibility of light control is strong.

Figure 14 The schematic diagram of the structure of the built-in Venetian blinds and insulating glass 1

Figure 15 The schematic diagram of the structure of the built-in Venetian blinds and insulating glass 2

No matter which type of built-in sunshade in the above three types of insulating glass, there are advantages and disadvantages in the use process.

Features of insulating glass blinds

l. Shading

The shading coefficient of insulating glass with built-in blinds ranges from Sc=0.18 to Sc=0.90. When the blinds are vertical, they can be used in all areas that meet the shading coefficient requirements in "Energy-saving Design Standard for Public Buildings". When the blinds are in a vertical state, the shading coefficient is Sc=0.18; when the blinds are in a horizontal state, the shading coefficient is Sc=0.83; when the blinds are in a folded state, Sc=0.90. The shading coefficient when the blinds are horizontal and folded is the shading coefficient of the glass, but when the blinds are vertical, the shading coefficient is Sc=0.18. The direct solar transmittance is 0.16, which means that there is still a certain degree of visible light in the room when the blinds are in a vertical state. It can effectively block the strong solar radiation in the south in summer, which causes direct sunlight to the room, and improve the indoor light environment. Thereby reducing the indoor temperature and reducing the energy consumption of building air conditioning.

2. Energy saving

The insulating glass blinds are made of high-quality double-layer tempered glass, double-sided laminated glass, double-sided Low-E glass, etc., with aluminum blinds imported from Japan. According to the test results of national professional authoritative institutions, the K value (thermal conductivity coefficient) of hollow blinds can be as low as 1.8 or less, while the K value of ordinary hollow glass is 3.0; the K value of single-layer glass is generally 5.8.

3. Dustproof, oil fume and pollution-proof

The biggest advantage of insulating glass blinds is their dustproof, oil-fume, and pollution-proof performance. At the same time, due to the use of a high-tech magnetic induction transmission system, the closing opening, lifting, and lowering of the blinds are easier; the blinds do not need to be cleaned, saving time, effort, and money.

4. Fireproof

The insulating glass blinds are not burned by open flames, and will not release thick smoke in a fire. Double-layer tempered glass with aluminum blinds also has the function of blocking flame transmission, effectively reducing the probability of fire, and is a good fireproof product.

5. Sound insulation

Insulating glass can generally reduce indoor noise from RW-86 decibels to RW-45 decibels, and insulating glass blinds can reduce indoor noise to below RW-30 decibels, ensuring perfect sound insulation.

Common sense of use of insulating glass blinds

When purchasing insulating glass, pay attention to the following aspects:

1. Check the logo and certificate

Architectural (safety) insulating glass refers to the single glass that constitutes the insulating glass, which is safety glass (tempered glass or laminated glass) that has passed the 3C certification. Since the implementation of the certification, many manufacturers have passed the product certification and obtained the 3C certificate. Enterprises should silk-screen or paste the 3C logo on the body of the product they sell, or add the 3C logo on its smallest outer packaging and in the accompanying documents (such as certificates of conformity). When purchasing a product, you should first check whether there is a 3C mark, and check whether the manufacturer of the product has passed the mandatory product certification (with a 3C certificate and valid) through the Internet based on the company information, factory number, or product certification certificate, whether the product model and specifications are within the scope of the company's ability to pass the mandatory certification, and whether the certification certificate status is valid.

2. Check the appearance and quality

Check the appearance quality of the product. The insulating glass should not have stains, inclusions, and sealant splashes that hinder perspective, and there should be no foreign matter in the intermediate spacer. The sealant or strip should be applied evenly and continuously, firmly bonded to the glass surface, and no airways or bubbles should appear.

3. Send samples to a qualified testing agency for testing to confirm product quality

There are many key raw materials and production processes for insulating glass products. The quality of the raw materials and the control level of the production process affect the final quality of the product. In addition, the key performance of insulating glass cannot be identified from the appearance of the product, and can only be confirmed through experimental testing. Therefore, it is recommended that when purchasing insulating glass, especially when the batch is large, samples must be sent to a third-party testing agency for inspection and identification.

4. Confirmation of the energy-saving performance of insulating glass

When designing curtain wall glass and building doors and windows, there are certain requirements for the visible light transmittance, shading coefficient, heat transfer coefficient, dew point, and other performance parameters of insulating glass. To improve the energy-saving effect of insulating glass, people use different types of coated glass and tinted glass to synthesize insulating glass. The energy-saving performance of products is different due to the different glass sheets and structures of insulating glass. Therefore, before choosing insulating glass, the glass must be sent to a qualified third-party testing agency for testing and confirmation to ensure that the performance of the selected product meets the energy-saving design requirements or the performance requirements of energy-saving building exterior windows. When choosing high-transmittance Low-E coated insulating glass, because the coated surface is placed on the inside of the compartment cavity, it is not easy to identify and detect. Therefore, it is necessary to sample and inspect the products provided by the insulating glass supplier and ask professional testing agencies to identify them to prevent inferior products from being sold as good ones, or even fake products from being sold as real ones.

5. Handling, storage, and use of insulating glass

Insulating glass is generally packed in wooden boxes or pallets. Plastic or paper should be used to separate the glass, and soft materials should be used to fill the space between the glass and the packaging to prevent the glass from being scratched. Insulating glass should be stored vertically in a dry room. External impact should be avoided as much as possible during handling and use. Be careful not to scratch or abrade the glass surface when cleaning the glass.

For more information about insulating glass processing equipment and glass processing machinery, please click here to learn more.