Technical analysis of aluminum-wood composite doors and windows.

Along with the wood profiles in aluminum-clad wood doors and windows, in addition to meeting the basic requirements for the cross-section design of aluminum-clad wood doors and windows, aluminum-clad wood doors and windows also need to meet the structural strength and thermal insulation performance of aluminum-clad wood doors and windows in passive buildings. At present, China’s domestic requirement for the K value of the thermal insulation coefficient of profiles for passive doors and windows is not to be higher than 1.3W/m2·K. Since the standard conditions used in calculating or testing the U value in Europe are different from those in China, the outdoor value is generally around 0°C (depending on the local climate), while the domestic standard takes -20°C, and the outdoor convection heat transfer coefficient value is also different. Therefore, the average temperature of the glass cavity under EN/ISO standard conditions is about 10°C higher than that under the domestic standard system. As a result, the U value under the EN/ISO standard system is higher than the K value in China, and some parts can be about higher 0.1 W/(m2·K), that is, the foreign requirement for the thermal insulation coefficient of profiles for passive doors and windows is that the U value is not higher than 1.4 W/(m2·K). To meet this design requirement, the wooden profiles of passive aluminum-clad wood doors and windows are mainly solved through various structural methods such as increasing the thickness of the wood, laminating the wood and insulation composite materials, elastic links between the wood and the insulation composite materials, or cavity design.

Keywords: Passive aluminum-clad wood doors and windows, wood profiles, structure

1. Introduction

As a basic raw material, wood has the characteristics of low thermal conductivity and high sound insulation. At the same time, due to the natural properties of wood, if it is not handled properly, it will bend, twist, etc., thus affecting the normal use of doors and windows. This article will start from the characteristics of wood and the production and use scenarios of passive aluminum-clad wood doors and windows, and describe how to reasonably design and produce wood profiles for passive aluminum-clad wood doors and windows, thereby providing insights into the application of aluminum-clad wood doors and windows in passive buildings. Provide a theoretical basis for use.

2. Timber for aluminum-clad wood doors and windows

As a renewable natural resource, wood has the characteristics of low thermal conductivity, high sound insulation, and easy processing. There are tens of thousands of known wood species in the world, and due to different species, growing regions, and environments, the properties of wood such as texture, texture, water absorption, and thermal conductivity are also different. Therefore, according to the special use scenarios of doors and windows, it is necessary to select the corresponding wood type and quality to produce and process aluminum-clad wood doors and windows. The German VFF HO. 02: 2008-12 and VFF HO. 06-1/2 specifications stipulate the wood types and wood profile quality requirements that can be used in German aluminum-clad wood doors and windows, including a total of 10 types of needles. Leaf forest species and 23 broad-leaved forest species are suitable for processing aluminum-clad wood doors and windows. At the same time, due to the different densities of various wood species, their thermal conductivity and elastic modulus are also different.

According to the German DIN 68364 standard, Table 1 lists the basic physical parameters of wood profile types commonly used in aluminum-clad wood windows.

| Wood species | Density (moisture content 12+/-2% average) | Elastic modulus N mm2 | Tensile coefficient N mm2 | Bending coefficient N mm2 | Thermal conductivity W/(m2·K) |

| Red pine (coniferous forest) | 560 | 11.000~12.000 | 100~104 | 80~100 | 0.127 |

| Pinus sylvestris (coniferous forest) | 540 | 11.000~12.000 | 98~104 | 85~100 | 0.126 |

| Spruce (coniferous forest) | 470 | 10.000~11.000 | 80~90 | 40~50 | 0.083 |

| Larch (coniferous forest) | 590 | 12.000~13.000 | 105~107 | 47~55 | 0.182 |

| White oak (broadleaf forest) | 690 | 11.700~13.000 | 90~110 | 52~65 | 0.223 |

3. Structural form of wood profiles for aluminum-clad wood doors and windows

The wood itself is a heterogeneous basic material. The moisture in the wood will change with changes in the surrounding environment. Changes in moisture and differences in the wood drying shrinkage will cause the wood to bend, twist, and other deformations. Therefore, controlling the arbitrary absorption and loss of moisture in the wood and the reasonable structural design of the wood profiles can effectively prevent the deformation of the wood profiles. At present, to prevent the deformation of wood profiles in terms of structural design, the main construction methods of wood profiles for aluminum-clad wood windows are single-layer finger jointing and multi-layer bonding and pressing (more than 3 layers). Choosing cut-grained boards as outer skin panels makes the wood profiles more stable.

Figure Ⅰ illustrates the structural form of wooden door and window profiles.

Figure 1 Multi-layered structural wood profiles

4. Surface treatment of wood profiles for aluminum-clad wood doors and windows

When the moisture content of wood profiles is higher than 20%, fungi can easily reproduce in the wood, leading to mildew, rot, and other phenomena in the wood. Effectively controlling the random absorption and loss of moisture in wood is a key factor in ensuring the quality of wood profiles for aluminum-clad wood doors and windows. An important technical means to achieve this quality assurance is the surface treatment of wood-water-based paint. Generally, wood profiles for aluminum-clad wood doors and windows use a water-based paint construction process of 2 bottoms and 2 sides. The German standard HO.06-2/A1:2007-10 requires a paint film on the visible side of the wood profile (which can be exposed to ultraviolet rays). The dry film thickness is not less than 80 μm. The dry film thickness of the paint film on the non-visible surface (not exposed to ultraviolet rays) is not less than 50 μm. Only by meeting this standard can the wooden window be guaranteed to have a service life of more than 20 years under normal use.

5. Wood profile design in passive aluminum-clad wood doors and windows

The K value of the overall door and window thermal insulation coefficient of passive doors and windows is less than 1.0 W/m2·K, and the K value of the profile is required to be less than 1.3 W/m2·K. The design of wood profiles can be achieved by increasing the thickness of wood profiles, and adding insulation composite materials and cavities To realize the design, these three design solutions need to consider the bonding strength and structural strength of the profiles during the implementation process, as well as the cooperation between the wood profiles and the hardware, rubber strips, etc. during the use of doors and windows.

5.1 Pure solid wood passive wood profile structure

Pure solid wood passive wood profiles improve the thermal insulation performance of the profile by simply increasing the thickness of the wood profile. This design scheme takes full advantage of the low thermal conductivity of wood. Blindly increasing the thickness of wooden profiles increases the difficulty of designing doors and windows, especially when the window sash area is small. If the door and window cross-section design is unreasonable, scratches between the profiles and the tape may easily occur during the opening or closing process.

Figure 2: Pure solid wood passive wood profile node diagram, the total thickness of the wood structure is 102mm, and the thermal insulation coefficient Uf value can reach 1.05 W/m2·K.

*The above insulation coefficient adopts the U value used in Europe, which is different from the K value used in China.

Table II gives the thermal insulation coefficients of wood profiles produced from four representative types of wood in coniferous and broad-leaved forests according to the DIN4108 T4 standard. IV56 represents a wood profile thickness of 56 mm, and the structural form 18+20+18 represents a profile of Three layers laminated, and the thickness of each layer is 18 mm, 20 mm, and 18 mm respectively. Due to the different thermal conductivity of different woods, wood profiles of the same thickness achieve different thermal insulation effects.

| Pure solid wooden structure | IV56 | IV68 | IV78 | IV88 | IV92 | IV102 | IV112 | |

| Red pine/Pinus sylvestris (Thermal conductivity) | Structure type | 18+20+18 | 22+24+22 | 24+17+17+22/ 26+26+26 | 24+20+20+24/ 30+28+30 | 23+23+23+23/ 31+30+31 | 26+25+25+26/ 34+34+34 | 28+28+28+28/ 38+36+38 |

| Thermal insulation coefficient (U value) | 1.66 | 1.44 | 1.31 | 1.18 | 1.14 | 1.05 | 0.97 | |

| White Oak/Red Oak (Thermal Conductivity) | Structure type | 18+20+18 | 22+24+22 | 22+17+17+22/ 26+26+26 | 24+20+20+24/ 30+28+30 | 23+23+23+23/ 30+31+30 | 26+25+25+26/ 34+34+34 | 28+28+28+28/ 38+36+38 |

| Thermal insulation coefficient (U value) | 2.22 | 1.96 | 1.79 | 1.64 | 1.59 | 1.47 | 1.37 |

It can be seen from this table that if the profile insulation coefficient K value is to be less than 1.3 W/m2·K, the thickness of the wood profile using red pine or Scotch pine as raw material must be at least 88 mm.

5.2 Composite lamination structure of solid wood and composite materials

Composite lamination of solid wood and thermal insulation composite materials is achieved by adding thermal insulation materials with similar drying shrinkage ratios to wood but lower thermal conductivity during the lamination process of multi-layer wood profiles. This design solution can greatly improve the thermal insulation performance of wood profiles without increasing the thickness of the wood profiles. However, due to the multi-layer gluing of different materials, it is necessary to consider the compatibility and stability of other materials and wood during the gluing process and later use. While ensuring the thermal insulation coefficient of wooden profiles, the structural strength of the profiles is also taken into consideration.

Figure 3: Node diagram of the structural form of thermal insulation composite material pressed between solid wood, 27mm thick wood + 24mm thick composite insulation material + 27mm thick wood. If 24mm thick Purenit M 550 is selected as the insulation material, the thermal insulation coefficient Uf value can reach 1.08 W/m2·K.

*The above insulation coefficient adopts the U value used in Europe, which is different from the K value used in China.

Table III shows the thermal insulation coefficient after lamination of Korean pine/Pinus sylvestris and three commonly used wood profile insulation materials in Europe (high-strength XPS, Purenit M 550, Puren RG 200) according to the DIN4108 T4 standard. 18+20+18 means that the profile is laminated in three layers, and the thickness of each layer is 18 mm, 20 mm, and 18 mm respectively. Due to the different thermal conductivity of different woods, wood profiles of the same thickness achieve different thermal insulation effects.

| Red pine/Pinus sylvestris (thermal conductivity DIN4108 T4) | IV68 | IV78 | IV88 | IV92 | |

| Pure solid wood structure | Structure type | 22+24+22 | 26+26+26 | 30+28+30 | 24+22+22+24 |

| Thermal insulation coefficient (U value) | 1.44 | 1.31 | 1.18 | 1.14 | |

| Solid wood plus high-strength XPS insulation board | Structure type | 22+24+22 | 27+24+27 | 32+24+32 | 34+24+34 |

| Thermal insulation coefficient (U value) | 1.10 | 1.01 | 0.94 | 0.91 | |

| Solid wood plus Purenit M 550 | Structure type | 22+24+22 | 27+24+27 | 32+24+32 | 34+24+34 |

| Thermal insulation coefficient (U value) | 1.17 | 1.08 | 0.99 | 0.97 | |

| Solid wood plus Puren RG 200 | Structure type | 22+24+22 | 27+24+27 | 32+24+32 | 34+24+34 |

| Thermal insulation coefficient (U value) | 0.90 | 0.84 | 0.79 | 0.77 | |

(IV represents the thickness of the wood profile, IV68 represents the profile thickness of 68 mm, the thermal insulation coefficient in the above table is the Uf value tested according to the DIN4108 T4 standard)

5.3 Solid wood and composite elastic link structures

The elastic link structure of solid wood and composite materials is to use screws or buckles to connect the wood profiles and insulation materials separately during the design of the door and window system without changing the structure of the wood profiles. This design can greatly improve the thermal insulation performance of the wood profile without changing the thickness of the wood profile itself. However, since the existing profile is connected to the insulation material through elastic links such as screws or buckles, the thickness of the profile is increased, making it more difficult to design doors and windows with a small opening area.

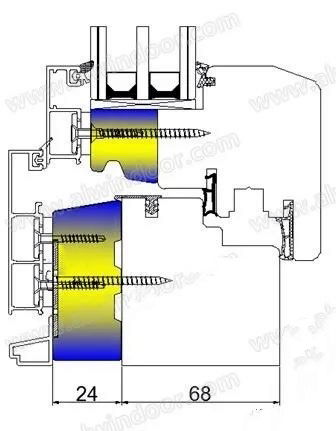

Figure 4 Node diagram of the elastic link between solid wood and composite materials.

The thickness of the wood profile is 68mm. If 24mm thick Purenit M 550 is selected as the insulation material, the insulation coefficient Uf value can reach 0.97 W/m2·K.

picture

*The above insulation coefficient adopts the U value used in Europe, which is different from the K value used in China.

Table IV shows the thermal insulation coefficient after lamination of Korean pine/Pinus sylvestris and three commonly used European wood profile insulation materials (XPS, Purenit M 550, Puren RG 200) according to the DIN4108 T4 standard. 18+20+18 means that the profile is laminated in three layers, and the thickness of each layer is 18 mm, 20 mm, and 18 mm respectively. Due to the different thermal conductivity of different woods, wood profiles of the same thickness achieve different thermal insulation effects.

| Red pine/Pinus sylvestris (thermal conductivity DIN4108 T4) | IV68 | IV78 | IV88 | IV92 | |

| Pure solid wood structure | Structure type | 22+24+22 | 22+10+24+22 | 24+20+20+24 | 24+22+22+24 |

| Thermal insulation coefficient (U value) | 1.44 | 1.31 | 1.18 | 1.14 | |

| Solid wood plus high-strength XPS insulation board | Structure type | 68+24 | 78+24 | 88+24 | 92+24 |

| Thermal insulation coefficient (U value) | 0.91 | 0.85 | 0.80 | 0.78 | |

| Solid wood plus Purenit M 550 | Structure type | 68+24 | 78+24 | 88+24 | 92+24 |

| Thermal insulation coefficient (U value) | 0.97 | 0.9 | 0.84 | 0.82 | |

| Solid wood plus Puren RG 200 | Structure type | 68+24 | 78+24 | 88+24 | 92+24 |

| Thermal insulation coefficient (U value) | 0.77 | 0.73 | 0.69 | 0.68 | |

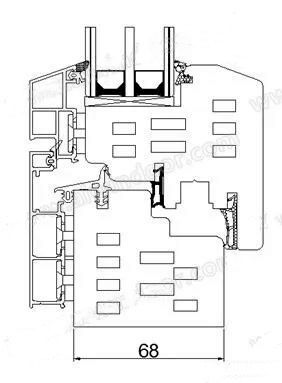

5.4 Cavity wood profile structure

Cavity wood profiles introduce the concept of cavity design into the profile structure of wood profiles and combine it with the low thermal conductivity of the wood itself to achieve better thermal insulation effects. This design solution can improve the thermal insulation performance of wood profiles without increasing the thickness of the wood profiles. However, due to the cavity design concept, the structural strength of the profiles is affected. When designing the wooden profile structure, it is necessary to consider the structural load-bearing coefficient and wind pressure resistance of the wooden profiles during the use of doors and windows, as well as the corners of the doors and windows when they are assembled.

Figure 5 Node diagram of cavity wood profile, profile thickness is 68mm, thermal insulation coefficient Uf value can reach 1.12 W/㎡·K

*The above insulation coefficient adopts the U value used in Europe, which is different from the K value used in China.

Cavity-type wood profiles have different cavity design sections, and the thermal insulation performance of the wood profiles is also different. Table 5 is the data measured by the German IFT according to the section designed by the German Noka Wood Industry Co., Ltd.

| Red pine/Pinus sylvestris (thermal conductivity DIN4108 T4) | IV68 | IV78 | IV88 | IV92 | IV102 | |

| Pure solid wood structure | Structure type | 22+24+22 | 22+17+17+22/ 26+26+26 | 24+20+20+24/ 30+28+30 | 23+23+23+23/ 31+30+31 | 26+25+25+26/ 34+34+34 |

| Thermal insulation coefficient (U value) | 1.44 | 1.31 | 1.18 | 1.14 | 1.05 | |

| Cavity type wood profile | Structure type | 22+24+22 | 22+17+17+22/ 26+26+26 | 24+20+20+24/ 30+28+30 | 23+23+23+23/ 31+30+31 | 26+25+25+26/ 34+34+34 |

| Thermal insulation coefficient (U value) | 1.12 | 1.04 | 0.97 | 0.94 | 0.88 | |

Other high-insulation wood profile structures

In addition to the above four structural forms as solutions, to meet the needs of different usage scenarios, the above four structural forms can also be used in combination, such as cavity profile design plus insulation materials, etc., wood profiles used for aluminum-clad wood doors and windows in passive buildings.

6. Use of passive aluminum-clad wood doors and windows wood profiles

At present, most domestic aluminum-clad wood door and window manufacturers generally produce the IV78, IV68, or IV58 series. The wood thicknesses of these three series of wood profiles are 78 mm, 68 mm, and 58 mm respectively. Without taking other technical measures, even if using Scotch pine or Korean pine with a low thermal insulation coefficient, the thermal insulation coefficient Uf value is 1.31W/m2·K when the wood thickness is 78 mm, which still cannot meet the design requirements of passive doors and windows.

Based on the current technical requirements that the K value of the entire passive door and window in China is not higher than 1.0W/m2·K, and the K value of the profile insulation coefficient is not higher than 1.3W/m2·K, if aluminum-clad wood door and window companies do not change the original doors and windows System design allows direct procurement of wood profiles designed with wood cavity designs or composite pressed profiles of solid wood and composite materials. However, when using wood profiles with this structure, door, and window companies need to determine the design cross-section of the wood profiles with the wood profile manufacturer to ensure the structural strength and gluing strength of the wood profiles. If the thickness of wood is increased or the elastic link between solid wood and composite materials is used, door and window companies need to redesign the door and window cross-sections to ensure that there will be no scratches on the strips and profiles during the use of doors and windows.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.