Analysis of Insulating Glass Warm Edge Spacers on Seattle Space Needle Project.

The first issue of LIJIANG Glass mainly introduced theoretical formulas and the importance of U-value in hot climates. The second issue used model data to analyze the application of broken bridge profiles in hot climates. This issue is the last article, borrowed from the Seattle Space Needle in the United States. The case of tower renovation is used to demonstrate the important role of warm-edge spacers for insulated glass in reducing cooling loads in summer, heating loads in winter, and improving comfort throughout the year.

These three articles demonstrate through data analysis the effectiveness of thermal insulation of glass curtain wall profiles in hot climates and the importance of using warm edges for insulating glass. Combined with the consideration of the thermal insulation function of glass curtain wall buildings, it provides a reference for glass deep processing practitioners on the processing methods and application selection of insulating glass spacers in the middle and high latitudes of the northern hemisphere. Leave a comment to share your opinion is our pleasure.

Author | Helen Sanders, Ph.D.Facade Tectonics 2020 World Congress

Glass edges are equally important

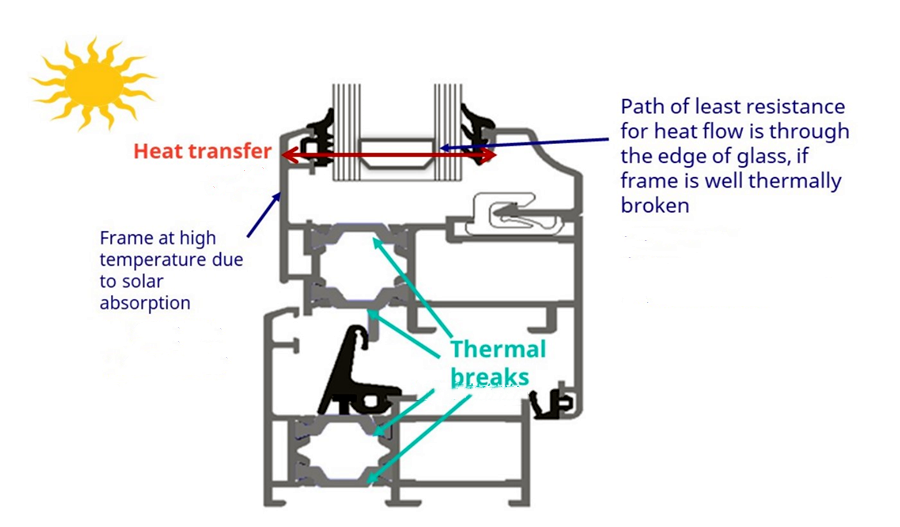

Generally speaking, taking glass curtain wall buildings as an example, the cooling and heating of the indoor temperature and the transfer of heat usually flow along the path of least resistance. Therefore, for broken bridge windows with good thermal insulation properties, the solar heat gain is absorbed by the outer profile, and since the edge of the insulating glass is composed of highly conductive spacing materials such as aluminum alloy, the heat will be transmitted to the room through the edge of the glass through conduction (Figure 8). Just like optimizing window frame profiles in hot climates, it is important to thermally insulate the glass edges using high-performance and durable warm-edge spacers.

Figure 8 Cross-section of a typical broken bridge-insulated aluminum window

After the window frame is designed with thermal insulation, the edge of the glass becomes the path with the least resistance to heat flow.

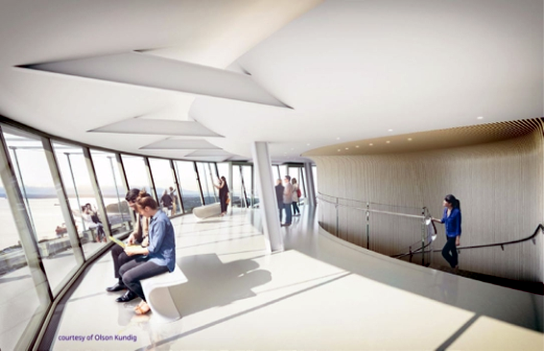

The recent renovation project of the Space Needle in Seattle, USA (Figure 9) is an example of glass curtain wall building renewal using high-performance warm edge spacers to reduce conductive heat gain (not heat loss). Taking the northern hemisphere as an example, Seattle's climate is obviously not "hot", but in this project, as with some large internal load buildings in cold climates, the most important thing to control is insulation rather than insulation, with the focus on controlling summer heat Heat is gained by conduction from the outside to the room, rather than heat radiated from the room to the outside.

Figure 9 The recently renovated Seattle Space Needle. Photo by Andrea Leopardi on Unsplash.

The glass area of the Space Needle renovation project in Seattle, USA, has increased by nearly 200%. In addition to meeting Seattle's strict local energy-saving regulations and the U.S. Green Building Council's LEED Gold performance requirements, the design team cannot increase the size of the refrigerator at will. Chiller specification has proven to be one of the most critical factors in determining glass performance requirements.

Insulated glass for visual viewing is arranged in two areas: the observation deck and the restaurant level.

Figure 10 (a) Observation level of the transformed Space Needle. Image provided by Olson Kundig Architects.

Figure 10 (b) The restaurant level of the Space Needle after renovation. The image copyright belongs to Nic Lehoux.

The observation deck of the Seattle Space Needle uses a reverse glass curtain wall with dark frame members extending to the outside of the facade. Due to the building's landmark status, this original design element had to be retained, but this resulted in significant heat gain due to the large surface area of the outer frame absorbing a large amount of solar heat. Since the curtain wall is structurally mostly made of glass, the only parts that can prevent heat flow from entering the room are the very small intervals on the metal curtain wall and the edges of the glass. Modeling results show that the use of high-performance warm edge spacers is critical for controlling solar heat gain because, in addition to meeting the U-value requirements under code to control heat loss, they also need to control the specifications of the chiller. Durable plastic hybrid stainless steel (PHSS) spacers were chosen for their insulating properties and baseline durability.

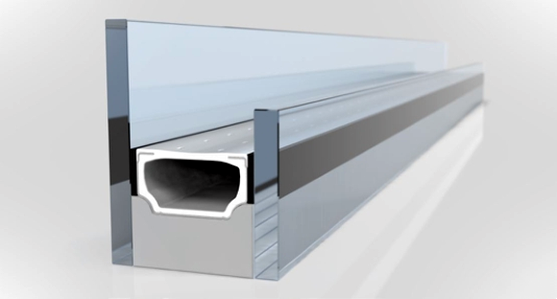

PHSS spacers have a traditional box spacer shape and are wrapped side and back with very thin stainless steel, extending completely from one primary sealing face to the other (Figure 11). Stainless steel sheets wrap the sides and back of the insulated glass with spacer bars for durability, while engineering plastic bridges the top and supports the steel internally for high-performance insulation.

Figure 11 Picture of plastic hybrid stainless steel (PHSS) spacers at the edge of insulating glass.

Using PHSS spacers, the sealant is in direct contact with the stainless steel. The stainless steel ensures the airtightness of the hollow layer of the insulating glass. The cavity can accommodate enough desiccant and has the same benchmark durability performance as traditional stainless steel or aluminum spacers. However, the advantage of PHSS is that it uses engineering plastics for thermal insulation, giving it the same high insulation performance as completely non-metallic spacers.

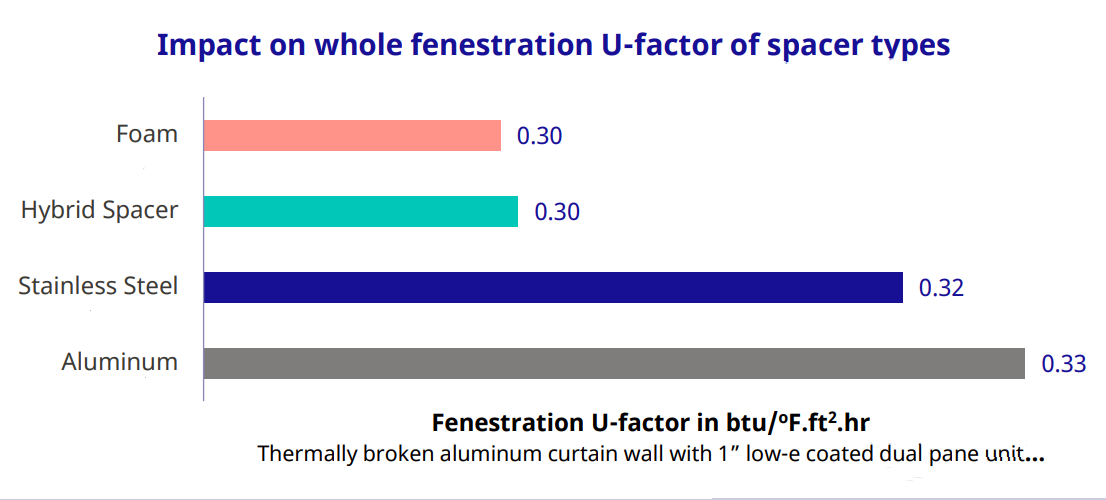

Comparison of the U-value of the entire window using 1-inch (2.5cm) Low-E double glass with 4 different types of spacers (Figure 12).

Figure 12 The impact on whole fenestration U-factor of spacer types

A similar situation exists on the restaurant floor of the Space Needle. The sloping floor-to-ceiling insulating glass 2 meters wide by 3 meters high is only supported by frame members at the top and bottom edges, and the vertical glass edges become the weakest point to control heat conduction. High-performance PHSS rigid spacers were again specified taking into account refrigeration unit peak loads and energy efficiency targets. In this application, the rigid design of the PHSS warm edge spacers is critical because of the need to resist torsional forces in the sill and roof conditions of the unsupported edge design.

Richard Green, P.E. (Front), the project's glazing design engineer, said: "We had to work closely with Arup's HVAC designers. We needed to maximize the performance of the glazing system. Using appropriate insulated glass spacers made the difference. Decisive. Many people use stainless steel as the standard, but we need better."

Conclusions and Future Directions

Results from field studies, building energy modeling analyses, and actual case studies all support the conclusion that reducing heat transfer through window frames and glass edges is critical to controlling building energy consumption in hot climates.

Future Directions: Thermal Comfort Assessment

In addition to energy efficiency, there is evidence that even in hot climates, high temperatures on the inside of a non-insulated window frame can lead to thermal discomfort for occupants. The potential for this discomfort is illustrated by the extreme inner frame surface temperatures of 48-54°C recorded on-site for non-insulated bridge frames (the temperature depends on the absorptivity of the window frame). Residents who are close to very hot curtain wall profiles indoors will feel thermal discomfort due to the high radiant temperature on the surface of the profiles. Even if the average ambient temperature in a room is theoretically within the "comfort" range, radiant temperature can be a major driver of thermal discomfort along with humidity and airflow.

The closer an occupant is to a glass window, the more likely the thermal environment they experience is affected by the radiant surface of the glass window, and the more likely they are to experience thermal discomfort. Any thermal discomfort results from the average radiant temperature of the surfaces surrounding the occupants (glass, window frames, opaque walls, floors, etc.) and the effects of direct solar radiation through the glass, plus the effects of air currents, humidity, operating temperatures, etc. Additional or compensatory effects.

To quantify this discomfort, further work could be carried out to calculate the average radiant temperature for envelopes with various window frames and glazing areas and glazing properties, and to incorporate the discomfort generated by direct solar exposure through sight areas The sense is distinguished from the effects of thermal radiation conduction generated by the temperature of the surrounding opaque frame and glass area.

Conclusion: Key Takeaways

Insulating the profiles and using high-performance warm-edge spacers can significantly reduce solar heat gain in doors, windows, and curtain walls, thereby reducing energy consumption and improving living comfort. The main points are as follows:

- Non-insulated window frames and glass edges can bring large amounts of heat into the building through solar absorption and secondary conduction mechanisms, resulting in high building cooling loads and causing thermal discomfort to occupants near the building envelope.

- Solar heat gain in the opaque part of the door, window, and curtain wall (profile area) depends on the absorptivity and U-value of the window profile. To achieve lower solar heat gain, use wider, more complex insulating strips to reduce heat conduction, and use light-colored profiles to reduce solar gain.

- Contrary to the U-value, full-window SHGC generally increases with window size because the SHGC of the window frame is lower than the SHGC of the center of the glass. However, if the insulation is not good, the solar heat gain coefficient of the window frame may be equivalent to the center of the glass, so it will be more difficult to meet SHGC requirements without reducing the visible light transmittance of the glass.

- In hot climates, reducing heat conduction through window frames and glass edges (U-value) has a significant impact on building energy consumption. Using high-performance curtain walls with wide insulating strips common in cold climate regions (U=1.6 W/m2K), compared to a non-insulated system with an SHGC of 0.25, the cooling load is reduced by the same amount as not using non-insulated structures in the model building Reducing SHGC from 0.25 to 0.21 has a similar effect. Designers should consider improving the U-value of the entire window (including the window frame and glass edge) and improving the solar heat gain coefficient in the center of the glass, as this strategy can provide more flexibility in glass selection and better lighting effects. , and potentially reduce costs.

- High-performance insulating strips and warm edge spacers should be widely used in buildings in all climate zones.

The last thing to say is that the SHGC calculation method of NFRC 200 (NFRC) does not consider the influence of different profile colors, but uses 0.5 as the standard absorption coefficient. Therefore, the actual solar heat gain coefficient of a door, window, or curtain wall with darker window frames may be higher than expected based on typical NFRC calculations. The impact of this difference on the performance of the building envelope depends on the frame-to-glass ratio of the building's doors, windows, and curtain walls. The greater the frame-to-glass ratio, the greater the impact.

Acknowledgments

Finally, the authors gratefully acknowledge the work of the Solar Energy Research Institute of Singapore (SERIS) on the field evaluation of broken bridge insulation designs, as well as Technoform, the Building and Construction Authority of Singapore, Meinhardt, Yongnam, and the Singapore Green Building Council for their support of this research. Thanks to Building System and Diagnostics (BSD) for providing building energy modeling services.

References

1. Building Construction Authority, “Guidelines on Envelope Thermal Transfer Value for Buildings”, version1.01(2004).

2. Building Systems and Diagnostics (BSD), “A Report on Thermal Performance of Fenestration For Green Mark Version 5.0”, (2016).

3. National Fenestration Rating Council (NFRC), ANSI/NFRC 200-2017, Procedure for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance at Normal Incidence, 2017.

4. Solar Energy Research Institute of Singapore (SERIS), “Pilot Study on Energy Savings Potential of Thermally Broken Aluminum Frames in the Tropical Climate”, (2016), commissioned by Technoform.

5. Wright, John L, Alex McGowan, “Calculating the Solar Heat Gain of Window Frames”, ASHRAE Transactions, 106 part 2 (1999) Zemanski, Mark W, Richard H. Dittman, Heat and Thermodynamics, sixth edition, McGraw-Hill, 1981, p86-87.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.