Detailed explanation of intermediate material selection and production process of laminated glass.

With the advancement of glass deep processing technology, the interlayer films of laminated glass are also constantly upgraded. Nowadays, PVB, EVA, SGP, PU, and other films are commonly used, and other materials are even added. What are the differences between these different films? How are they made into laminated glass? LIJIANG Glass will answer these questions one by one.

1. The PVB film glass

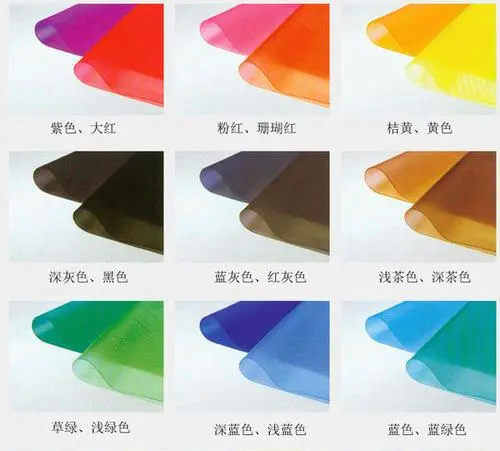

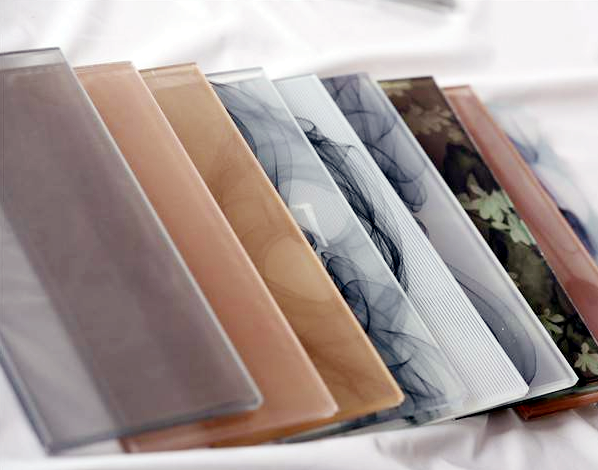

PVB is also called polyvinyl butyral ester, and the PVB film produced is more common in laminated glass. PVB film is widely used in automotive glass, architectural glass, etc. because it is non-toxic, odorless, and non-corrosive. It has good transparency, insulation, impact resistance, and stretchability. It is also light-resistant, cold-resistant, and aging-resistant. In production, it is also an ideal material for making safety glass. PVB film comes in a variety of colors and has anti-theft, anti-ultraviolet, sound insulation, heat insulation, and other properties.

Figure 1 More difference colors of the PVB film laminated glass

Precautions for storage and use of PVB film

- The number of stacking layers generally does not exceed three.

- The packaging is generally in wooden boxes or cartons to avoid collisions or crushing, tearing, or puncturing of the packaging during storage and transportation, and to prevent film wear, damage, and contamination.

- For films without an intermediate isolation film, storage, and transportation must be refrigerated; films with an intermediate isolation film can be stored at room temperature for a long time without opening the box, but must not exceed 32°C.

- The water resistance of PVB film is not good, and it is easy to peel off when soaked in moisture for a long time.

Figure 2 The wooden boxes to storage the PVB film

How to produce PVB laminated glass?

PVB film mainly uses the film hot pressing method (dry method) to produce laminated glass. The general production process of this process includes: cutting, joining operations, pre-pressing and preheating, unloading, autoclaving, and finishing.

1. The cutting

There are many ways to cut film. You can cut it manually on a workbench, or use mechanical cutting. The latter cuts the film more evenly and accurately. When cutting, the size of the PVB film needs to be slightly longer than the laminated glass, generally controlled at around 5mm, to avoid wasting the film and not causing shrinkage during heating and pressurization. If multiple layers of film are used, they should be cut in the same direction to ensure product quality.

Figure 3 How to cut the PVB film for laminated glass producing

2. The combination operation

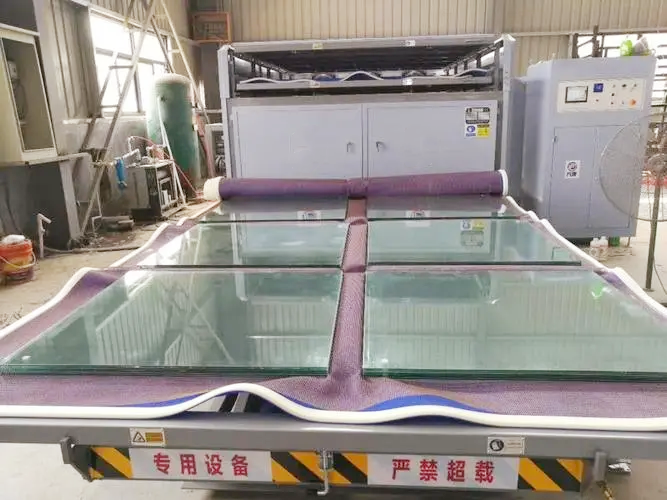

This step includes two steps: pre-processing and entering the combination room for combination.

Pretreatment requires loading, edging, washing and drying, and other steps on the glass, then applying glue and cutting if necessary. After the preprocessing is completed, you need to enter the lamination room for lamination operation.

Figure 4 The pretreatment operation to produce PVB film laminated glass

The co-production room environment has the following control requirements:

- It is required to have a dust-free and constant-temperature operation workshop with double doors for entry and exit to ensure the cleanliness of the film combination room.

- Control the temperature at 20~25℃ and the humidity at 23~28℃.

- Operators should wear cotton-free anti-static clothing made of special materials, their hair must not be exposed, and they should wear cotton-free gloves and masks.

Figure 5 The PVB film combination production room environment

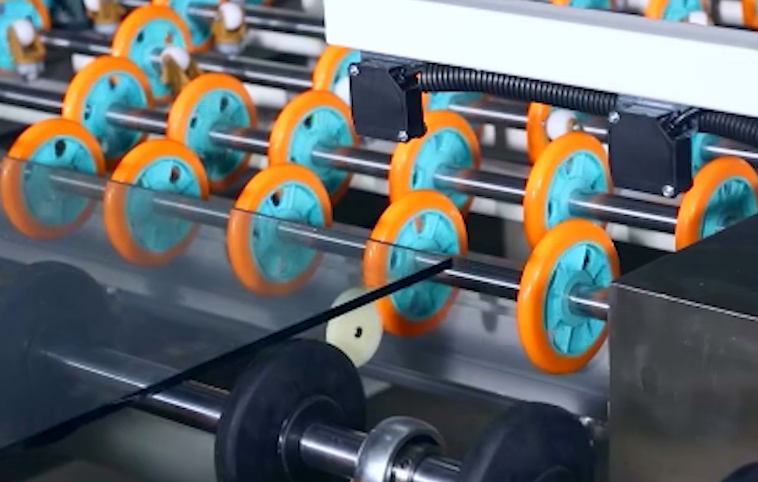

3. Pre-pressure and preheating

Before this step, it is necessary to check whether the remaining edges have been cut off, whether there are stains on the surface, etc.

The main purpose of the pre-pressure and preheating process is to remove the air between the glass and the film; to bond the glass and the film to avoid separation or misalignment during heat treatment; to seal the edges to avoid the penetration of the heat transfer fluid during high-temperature and high-pressure treatment in the autoclave.

In this process, the rolling process can be used for degassing and bonding. If the effect is not ideal or rolling cannot be performed, vacuum degassing can also be performed.

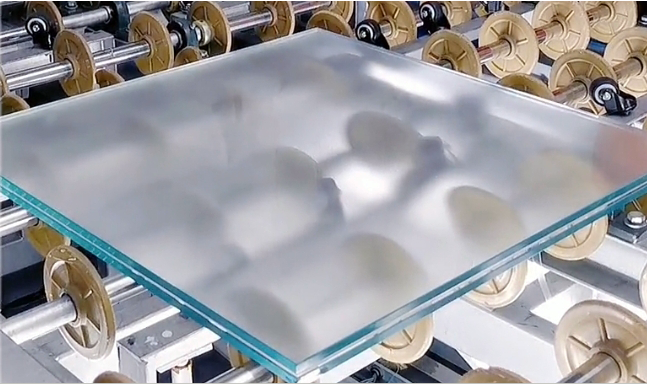

Figure 6 The PVB film Pre-pressure and preheating operation

4. The autoclave

This is the last process in the production of laminated glass, mainly for the film and glass to be better combined for long-term use. The heat treatment cycle in the autoclave has three stages: heating, heat preservation, and cooling. The entire cycle time is approximately 55 to 80 minutes.

- Heating: the temperature reaches 135~140℃, and the pressure reaches 0.5~1.5MPa. The pressurization rate is generally 0.06MPa/min, and the heating rate is 5°C/min.

- Insulation: The heat preservation time of single laminated glass is usually 10~25 minutes. The time setting mainly depends on the composition of the laminated glass.

- Cooling: Usually the cooling time is 25~35 minutes. The temperature in the autoclave must drop below 50°C before the pressure can be released gradually or instantaneously, otherwise, bubbles will inevitably form in the laminated glass.

Figure 7 The PVB film laminated glass autoclave

At this point, the production of PVB film laminated glass is completed, and there is still some finishing work, including inspection of the glass piece by piece, and if necessary, returning to the autoclave for pressure heating.

Figure 8 The PVB film laminated glass production line

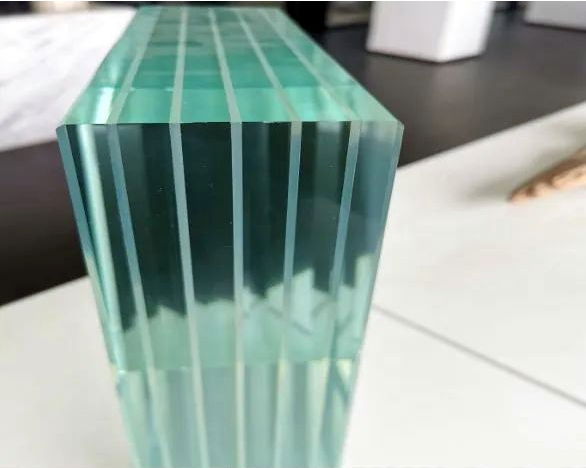

2. The SGP film glass

SGP film is an ionic film specially developed by DuPont. It contains about 1% metal sodium ions. Under the action of ionic bonds, the film has a very high bonding force with glass and has higher hardness and transparency than PVB film. However, SGP film is expensive and will not be used in general laminated glass.

Figure 9 The SGP film laminated glass

SGP laminated glass has very high safety performance. The load-bearing capacity of a piece of SGP laminated glass is twice that of PVB laminated glass, but the bending degree is only 1/4 of that of PVB laminated glass. It is often used in glass with high-quality requirements such as glass lighting roofs, glass exterior windows, glass corridors, glass curtain walls, etc. It is especially beneficial to the production of point-supported glass.

Figure 10 The glass corridors with SGP film laminated glass

How to store SGP film?

- Packaging: There are two packaging methods: sheet and roll. The former is placed on a horizontal pallet and sealed by waterproof and moisture-proof packaging. The latter is relatively simple to transport and hoist.

- Storage: When the package is not opened, special temperature control is not required for storage. It can be stored in a general room-temperature warehouse. The films will not stick to each other, but to ensure stable performance, it is best to store them at a lower temperature. Avoid being exposed to high temperatures for a long time; after opening the package, the film will absorb environmental moisture, resulting in reduced adhesion. It is recommended that the film be stored for no more than 3 years.

Figure 11 How to store and package the SGP film

How to produce SGP laminated glass?

The production process of SGP laminated glass is similar to that of PVB laminated glass. However, since SGP film has a certain hardness compared to PVB film, special attention must be paid to some matters and requirements in some aspects.

(1) Cutting

The SGP film is difficult to cut and can be cut with a sharp knife, automatic cutting table, punching, mechanical scratching, and then breaking. However, the film has good dimensional stability, can accurately fit the size, and does not require trimming after being cut properly.

(2) Pre-pressure and preheating

Special pre-pressing equipment is required for pre-pressing to ensure a tight fit between the film and the glass.

Figure 12 The SGP film laminated glass cutting

3. The EVA film glass

EVA film is a high-viscosity film material made of polymer resin as the main raw material through a special process. Due to its strong ability to bond glass, it has the characteristics of good fluidity, high elongation at break, and good moisture resistance, and is partly used in construction and other industries. However, the film has weak UV resistance and is prone to yellowing and aging after long-term exposure to light. Therefore, the UV resistance of the film can be improved by adding UV absorbers. At present, it is mostly used to produce decorative laminated glass, supplemented by other materials such as metal wire, paper, silk, cloth, plants, etc., so that the glass can obtain better decorative effects and be used for indoor partitions.

Figure 13 The EVA film laminated glass

How to make EVA laminated glass?

There are two main production methods: the vacuum one-step method and the grouting method (wet method).

1. The vacuum one-step method

This process allows the glass in the vacuum bag to exclude air without generating bubbles, uses atmospheric pressure to pressurize the glass, and melts the glass film at high temperatures, thereby firmly bonding the film material and glass together.

- Features

There is no need for an autoclave in the process. It is safe, practical, simple to operate, has a small investment, low cost, and quick results. Glass can be placed arbitrarily in the vacuum bag without being restricted by the thickness of the glass, saving time and energy. However, the melting point of EVA film is low, and the temperature during processing can reach about 110°C.

Figure 14 The EVA film laminated glass production line

- Processing equipment

The EVA film laminated glass production line mainly consists of four parts: a heating temperature control system, a heating body, a vacuum bed, a vacuum pump, and a vacuum bag. Among them, the vacuum bed is the most important component in the production process. It is made of a silica gel plate and can withstand high temperatures of about 230°C. It is used to place and support vacuum bags to ensure stability and safety during the production process.

- Specific process

Including glass washing, film preparation, lamination, vacuum exhaust, heating and holding, cooling, and removal.

- Vacuum exhaust

Put the combined glass into a vacuum bag, place a gauze around it to facilitate vacuum exhaust, and then perform cold pumping for 5 minutes when the vacuum value reaches 0.095Mpa. Empty the air in the silica gel bag, and then place it on the vacuum bed for the next step.

- Heating and maintaining

Heat the glass until the surface temperature reaches 50~60℃ and keep it for 20~30 minutes. Then continue heating until the surface temperature of the glass reaches 130~135℃ and keep it for 45~60 minutes. If the thickness of the film or the number of lamination layers increases, the heat preservation time can be appropriately extended.

- Cool and take out

During the cooling stage, the vacuum needs to be maintained and a fan can be used to cool down. Take it out when the glass temperature drops below 60℃.

2. Grouting method (wet method)

It uses dibutyl ester and methyl ester as the main body, plus other ingredients to form a glue solution, which is poured into a pre-made glass cavity and heated to solidify or illuminate. Because the products produced by this method are prone to defects and have many human factors, they are not suitable for automated production, so they are not a mainstream production method.

4. The PU film glass

PU film has the best performance among currently common film types and is mostly used for rail transit safety glass, high-end construction engineering laminated glass, large curved locomotive windshields, high-strength bulletproof glass, etc.

Figure 15 How to produce the rail transit safety glass

How to make PU laminated glass

The production process can be roughly divided into several steps: glass cleaning, ingredients, coating, lamination, bubble elimination, solidification, cooling, cutting, and edge grinding.

Different from the direct bonding of PVB film and glass, PU laminated glass requires the prepared ingredients to be coated on a piece of glass film, and then the two pieces of glass are bonded, so that there are subsequent heating, solidification, and cooling steps, and Production equipment such as batching machines and curing ovens are required.

The batching machine is used to accurately measure and mix PU ingredients to ensure uniformity and quality during coating.

The curing oven is used to provide the appropriate temperature and time to promote the bonding and curing of PU film and glass.

Figure 16 The PU film laminated glass

At this point, we believe you have a deeper understanding of the film types, production processes, and techniques of laminated glass. If you have any questions or want to know more about other knowledge about glass processing, please leave a message in the comment area.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.