LJTJ3370 Automatic Vertical Insulating Glass Sealing Robot Machine

LIJIANG Glass LJTJ3370 Automatic Vertical Insulating Glass Sealing Robot Machine has the characteristics of full insulating glass sealing edge, no bubbles, precise control of sealing output, high production efficiency, low labor intensity, and consistent sealing effect standards, which are well received by jumbo size insulating glass processing users.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJTJ3370 Automatic Vertical Insulating Glass Sealing Robot Machine

Product Description

- Equipped with a high-resolution precision photoelectric switch sensor that can detect glass thickness and sealing depth; the glass coating width can be automatically adjusted according to the input parameters. It is equipped with a Siemens PLC control system to realize automated transmission through servo motors and high-precision racks to ensure improvement in the glue coating accuracy of the equipment.

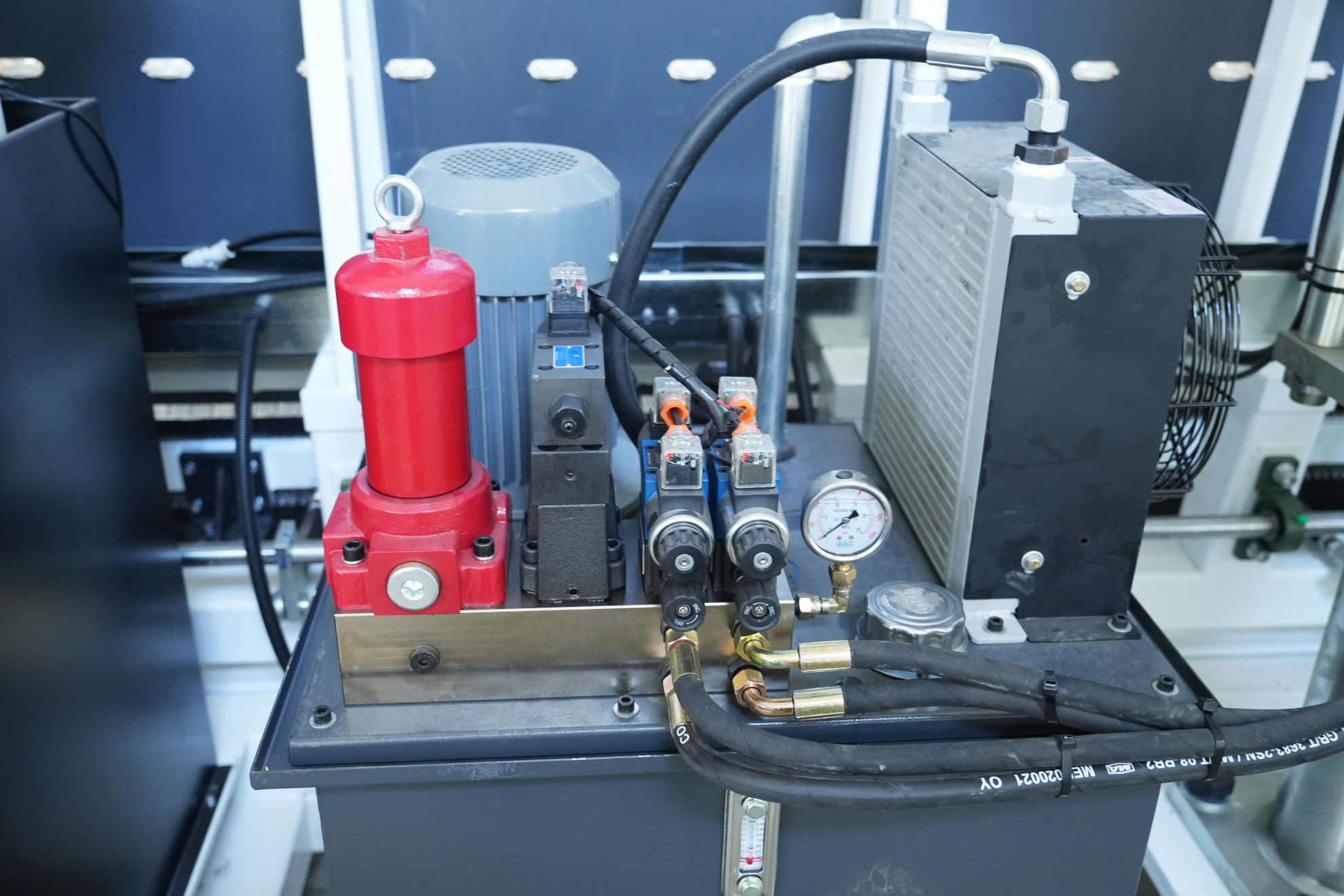

- It is equipped with an automatic glue replenishing function and adopts a unique pressure plate dual-channel sealing gasket structure to supply glue hydraulically to make up for the problem of glue overflow in the two-component glue barrel. Through the pressure control of the hydraulic station, the hydraulic station can meet the quantitative supply of oil to the driving cylinder, thereby controlling the quantitative supply of white glue A component, and then adjusting the proportion of B component glue through mechanical linkage to ensure a quantitative supply of black glue. ; It can automatically adjust the amount of glue output, greatly improving the sealing efficiency and saving the amount of sealant.

- The glue head adopts a new front glue head and has a special floating structure to ensure that the glue head does not damage the glass while meeting the requirements of a close fit with the glass. It can also adapt to the insulating glass within a certain range. Misalignment error; equipped with a glass pressing device to ensure safer movement of glass during transmission and gluing.

- The three-layer insulating glass can be sealed with glue. When sealing three-layer glass, first apply glue to the insulating glass of the first cavity. After the sealing process of the first cavity is completed, the glue head will automatically adjust the angle and then apply glue to the second cavity. The insulating glass is coated with glue.

- The V-belt adjustment structure can adjust the V-belt according to the thickness of different glass; it adopts a transmission method that combines high-quality and precise multi-row roller chains and V-belts. The rollers are in contact with the processed surface of the beam, so the friction is small and the transmission is smooth. High power; the glued glass runs smoothly, ensuring a good glue coating effect.

- Equipped with a rubber head pressing device, the pressure of the mobile cylinder of the rubber head can be adjusted through a precision electrical proportional valve to achieve compression of the rubber head, so that the rubber head adheres to the glass more smoothly.

- Equipped with a glue head centering structure, the glue head can be adjusted according to different thicknesses of glass. No matter how thick the insulating glass needs to be sealed, the glue nozzle can always be aligned with the center of the cavity of the insulating glass, resulting in a better glue effect.

- Equipped with a cleaning function, when the sealing equipment is not used for a long time, the glue supply pipeline needs to be cleaned (glue flushing) to prevent the glue supply pipeline from being solidified. When the cleaning function is performed, the mixed glue in the mixer pipe will be discharged, which can better protect the pipeline and prevent the rubber pipe from solidifying.

- When sealing the four corners of the insulating glass, the micro-glue filling function is optional to ensure the quality of the glue at the corners; the sealing effect can ensure that the edges of the insulating glass are full and air-free, the corners are full, and the four sides of the insulating glass are smooth and The sealant surface is smooth and even, no need for secondary corner trimming.

- Equipped with a "connection" function to the insulating glass production line, the sealing line also has the functions of unilateral gluing, alarm prompts, automatic hazard determination, and equipment locking.

- Servo motors, PLC controllers, low-voltage electrical appliances, sensors, and photoelectric switches are all from well-known foreign brands to ensure safe and reliable operation of the equipment and long service life; the human-machine operation interface is friendly and simple, making it more convenient for users to operate.

Advantages & Features

- Japan Yaskawa servo system control, full automatic nd high-efficiency sealing machine

- 4 sections, can storage glass

- Adopt timing belt, smooth transfer and accurate position

- Automatically repair glass corners with scraper and roller

- Automatically measure the glass size and the glass sealing depth (30mm)

- Every auto-function is with manual operation

- Can coat special type of double glass

- Shape glass with optional edges, step glass, triple glass (Optional)

- One set of booster pump controls two groups of sealants (Optional)

- Can use silicone, polysulfide and silicone structural sealants

- Glue head is in the front of the machine, whih is easy for coating step glass

- Can be connected with insulating glass processing line

- With code scanning function (Optional)

he Smooth Sealing Surface

The High-precision Servo Control System

The Glass Coating

Sealant Pump A and Sealant Pump B

Main Technical Parameter

| Item. | Spec. |

| Max. glass processing size | 2500*4500mm |

| Min. glass processing size | 400*280mm |

| Glass thickness | 3-15mm |

| Diameter of grinding wheel | 200mm |

| Conveyor height | 500mm |

| Edge deleting width | 10-50mm |

| Transmission speed | 29m/min |

| Edge deleting speed | 2-29m/min |

| Abrasive wheel width | 10/12/15mm |

| Grinding wheel speed | 0~3000r/min |

| Total air consumption | 100L/ min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50Hz 3.35Kw |

| Dimension | 9700mm*2500mm*3400mm |

| Total weight | 3700Kgs |

The System Structure and Hardware Selection

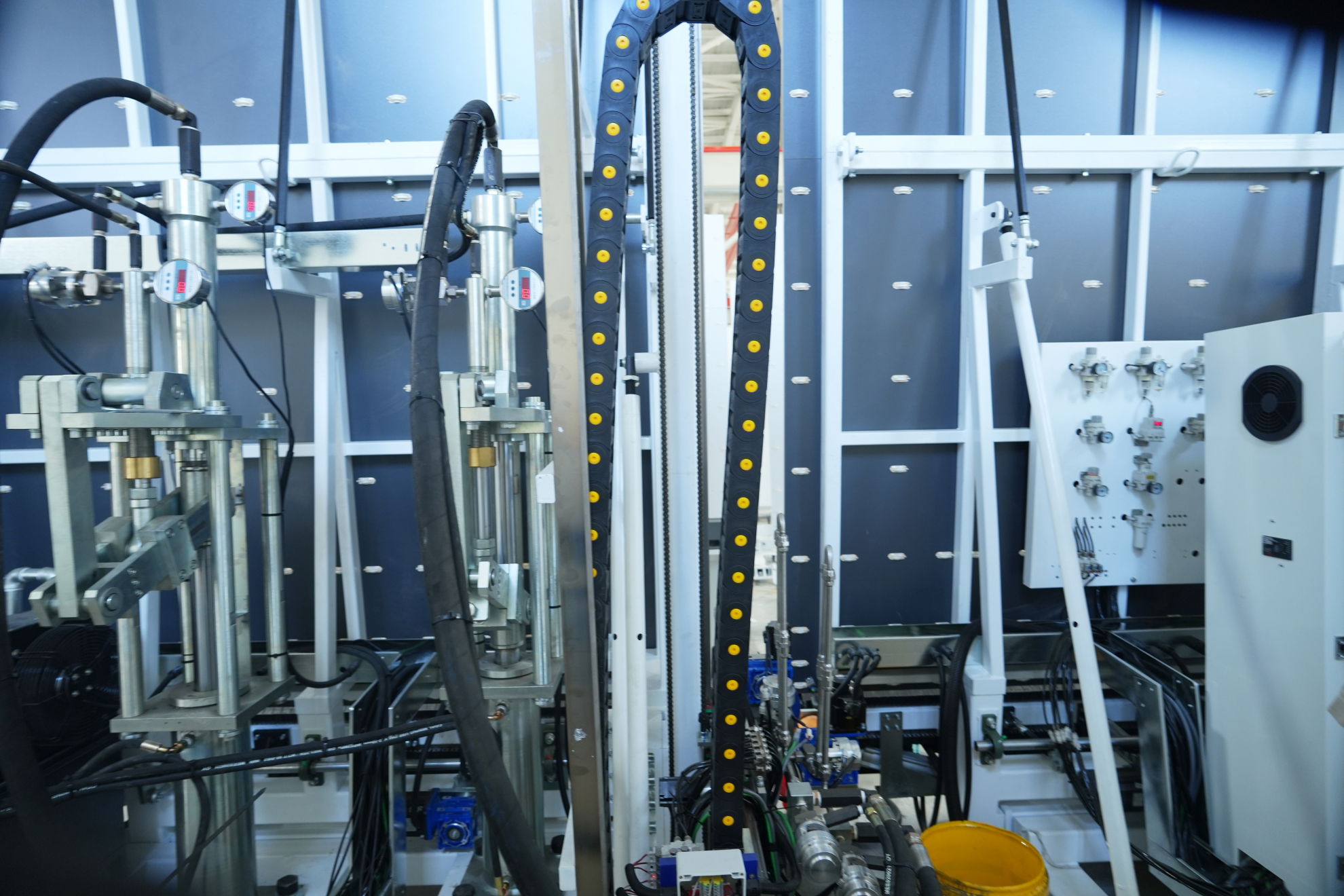

The system is mainly composed of mechanical and electrical parts. The newly-added tray and Y-axis guide rail in the mechanical part are newly-added structures. As shown in Figure 1.

1. Support table

2. Guide support beam

3. Tray

4. Glue gun fixing column

5. X-axis guide rail

6. Y-axis guide rail

The electrical system includes the upper computer control part and the lower computer. The upper computer completes the real-time display and control of the glue application process information. The lower computer PLC accepts the signal from the field sensor, executes the program to process the data, and drives the execution unit. The selection of the main components is shown in Table 1.

Table 1 The selection of the main components from LIJIANG Glass Automatic Insulating Glass Sealing Robot

| NAME | ORIGIN | BRAND |

| Servo motor | Taiwan | TAIDA |

| PLC | Taiwan | TAIDA |

| Pneumatic component | Taiwan | AAIRTAC |

| Low pressure electricity | Germany | SIEMENS |

| Circuit breaker | Germany | SIEMENS |

| Sensor switch | Korea | AUTONICS |

| Approach switch | Korea | AUTONICS |

| Limit switch | Taiwan | TEND |

| Connector | Germany | SIEMENS |

| Frequency converter | France | SCHNEIDER |

| Main Button | France | SCHNEIDER |

| Intermediate relay | Japan | OMRON |

The Servo Unit Parameter Setting

The normal operation of the servo unit requires the relevant parameters to be set as follows:

(1) Setting of speed control mode

When the glue output of the glue dispenser is constant, the glue can be applied even when the servo motor speed is stable, so set the servo unit to speed control mode, that is, Pn000.1=0. Use the proportional relationship between input voltage and speed to set the speed input command. When the set speed command input is +9V, the forward speed of the motor is 1500r/min, and when the input is +3V, the forward speed of the motor is 500r/min. Pn300=900, the "rEF_0" attribute of Fn009 is set to "donE".

(2) Setting of start and stop time

To get smoother constant acceleration and deceleration, it is necessary to set its soft-start function. as shown in picture 2. In the figure, Pn305 is the time required for the motor to reach the maximum speed from the stopped state, Pn306 is the time for the motor to reach the maximum speed from the maximum speed, ta is the actual acceleration, TB is the actual deceleration, nN is the maximum speed or rated speed, and n is the actual Operating speed.

The voltage U and speed n of the PLC analog output signal meet:

According to experience, adjust the acceleration and deceleration time setting ta=tb=100ms, nN=1500r/min, use the above formula to set Pn305 and Pn306.

(3) Setting of basic operating functions

Combined with the control requirements, the control of the servo unit needs to meet the servo ON always effective, the forward and reverse control of the guiding support beam and the tray; over-travel protection; motor free-running stop and emergency stop. The parameters are set as:

Pn50A.1=0, Pn000.0=0, Pn50A.3=2, Pn50B.0=3, Pn001.1=2, Pn001.0=2.

The Software Development

(1) PLC software design

The PLC program adopts a modular design method and is completed with function blocks. FC1 is initialized, and the tray is reset through the magnetic sensor; FC2 collects information from the host computer and selects the operating speed of the servo motor according to the glass specifications determined by the host computer; the initial position of the FC3 glass is confirmed, and the optical fiber sensor detects whether to enter the automatic four sides Gluing process; FC4 four-side gluing function, the gluing process has 4 sequential states, state 1 is the X-axis, state 2 is Y axis, state 3 is X-axis and state 4 is Y-axis; FC5 Detect the arrival of the next glass. If it is detected within the set time, the specifications of the glass will be confirmed. If the next glass is not detected, the control process will be completed.

(2) MCGS configuration software design

The main screen of the host computer monitoring system includes four sub-screens: user login, manual/automatic control, communication test, history query, and printing. Before performing control or parameter setting, the communication connection between the PLC and the host computer needs to be tested. The start, manual, and automatic detection of all motors, as well as the detection of sensors, use the Light control to display the detection status, and the connection status is distinguished by color. After entering the manual/automatic control mode, first, select the glass specifications, determine the amount of glue and the motor running speed, and then enter the control mode. Each servo motor can realize forward and reverse manual/automatic, and there is an interlock between the two. In addition, the specifications, processing time, and servo alarm conditions of the coated glass are displayed, and historical data conditions can be inquired and printed.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Problem Analysis of Insulating Glass Sealing Robot Equipment

Trouble analysis:

(1) The sheath of the glue nozzle is damaged.

Solution: Change the sheath.

(2) The aluminum groove depth detection probe slipped onto the glass when walking.

Solution: Adjust the probe so that it walks in the center of the aluminum groove.

(3) The advancing force of the rubber blocking plate and the rubber scraping plate is too great.

Solution: Adjust the speed of the advancing cylinder.

Problem 2. The machine head always pushes the glass away when it moves forward.

Trouble analysis:

(1) The machine head traveling positioning bolt is loose.

Solution: Condition and secure.

(2) The glass positioning is loose, making it lose its effect.

Solution: Set your positioning.

(3) The amount of movement before and after the suction cup is too large or the vacuum generator of the suction cup is damaged. Solution: Repair.

(4) The forward force of the forward cylinder is too large.

Solution: Adjust the traveling speed.

Problem 3. The various actions during work are not coordinated.

Trouble analysis:

(1) The setting is incorrect.

Solution: Reset.

(2) The pneumatic system accessories are aging.

Solution: Replace with new pneumatic accessories.

Problem 4. The motor is sometimes fast and sometimes slow.

Trouble analysis:

(1) The aluminum groove is not straight.

Solution: The aluminum channel should be straight.

(2) The guide rail is not straight or the sliding bearing is damaged.

Solution: Replace new guide rails or sliding bearings.

Problem 5. Transmission parking is inaccurate.

Trouble analysis:

(1) The driving switch is loose.

Solution: Fix the driving switch.

(2) The braking system of the transmission system is damaged.

Solution: Replace with new brake transmission parts.

Problem 6. During the sealing process, sometimes the car stops and starts the next action before it is finished, damaging the glass.

Trouble analysis:

(1) The fiber optic head in front of the machine head is blocked by glue. Solution: Organize.

(2) The fiber head nut is loose or skewed. Solution: Fix it.

(3) There is dirt on the surface of the glass. Solution: Clean the glass surface.

(4) The detection distance is too small, which may cause vibration when walking, affecting detection. Solution: Adjust the detection interval.