LJLQ-2000 Automatic Vertical Glass Washing and Drying Machine

LJLQ02 Automatic Vertical Glass Washing and Drying Machine could wash max glass of 2500 mm*3500 mm, which machine is suitable for deep processing of small format glass, more large size and less size of flat glass washing could be optional.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJLQ-2500 Vertical Glass Washing and Drying Machine

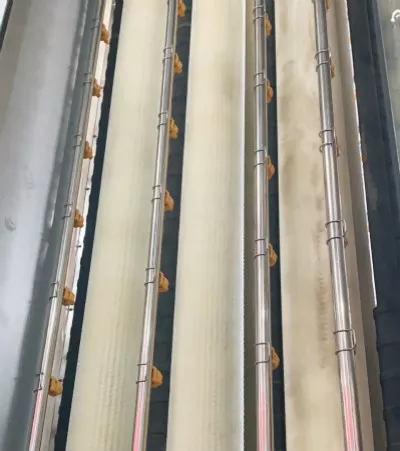

The LIJIANG Glass Automatic Vertical Glass Washing and Drying Machine, which is equiped with the steel structure, and protective cover are all made of high-quality stainless steel. It is divided into glass washing and drying sections by conveying rollers, cylindrical brushes (the brush material is made of high-temperature resistant nylon wire) driving devices, water spray pipes, and water supply system, wiper blade, air knife air filter, silencer device, etc.

- Three pairs of cylindrical brushes are independently driven by three asynchronous motors. The first and second pairs of brushes are pre-washed. The third pair of brushes can be cleaned with deionized water and sprayed with deionized water on the glass (three brushes and four showers), water treatment optional) high-pressure water nozzle is removable for washing and easy to maintain.

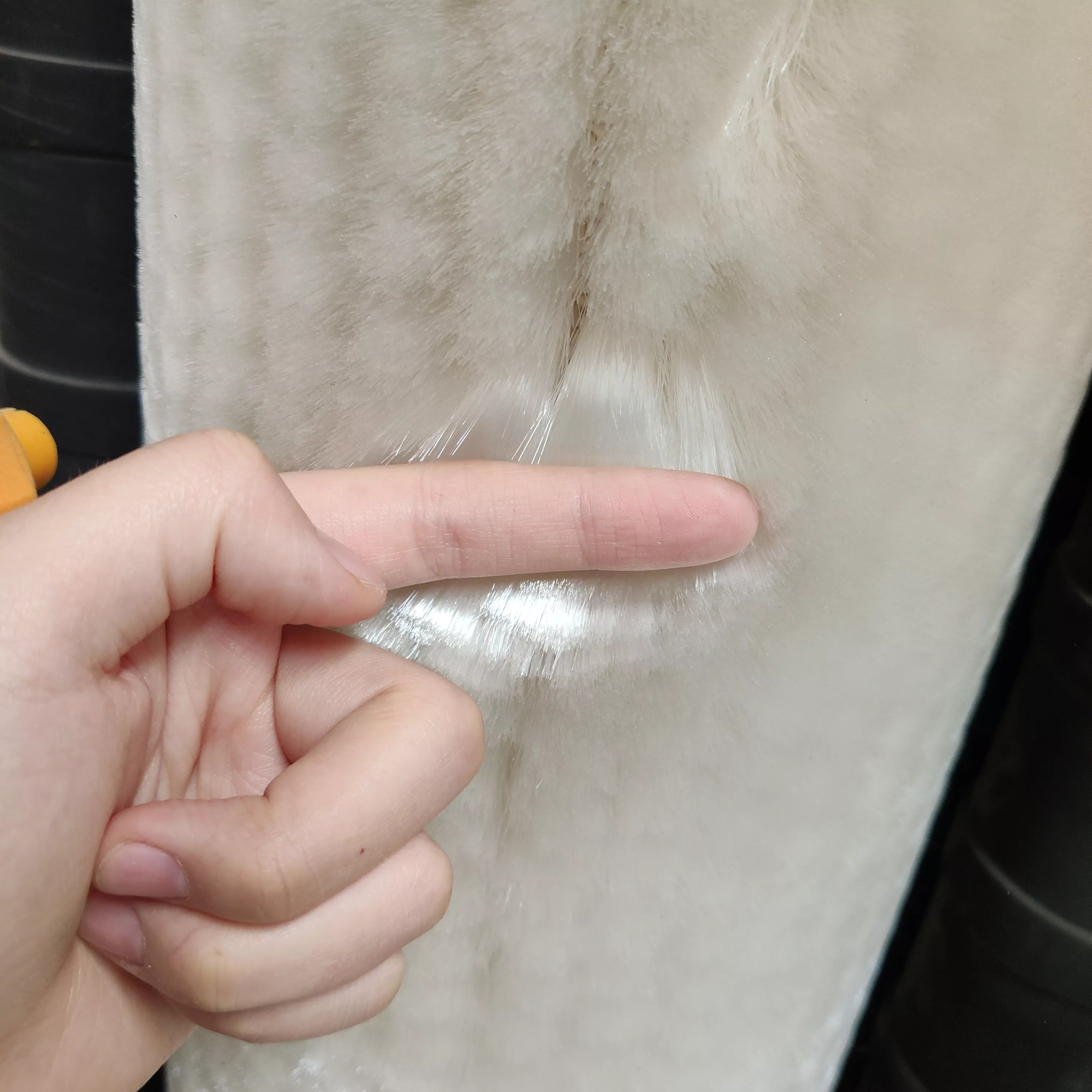

- The brush could wash different thicknesses and types of glass (Low-E glass is optional).

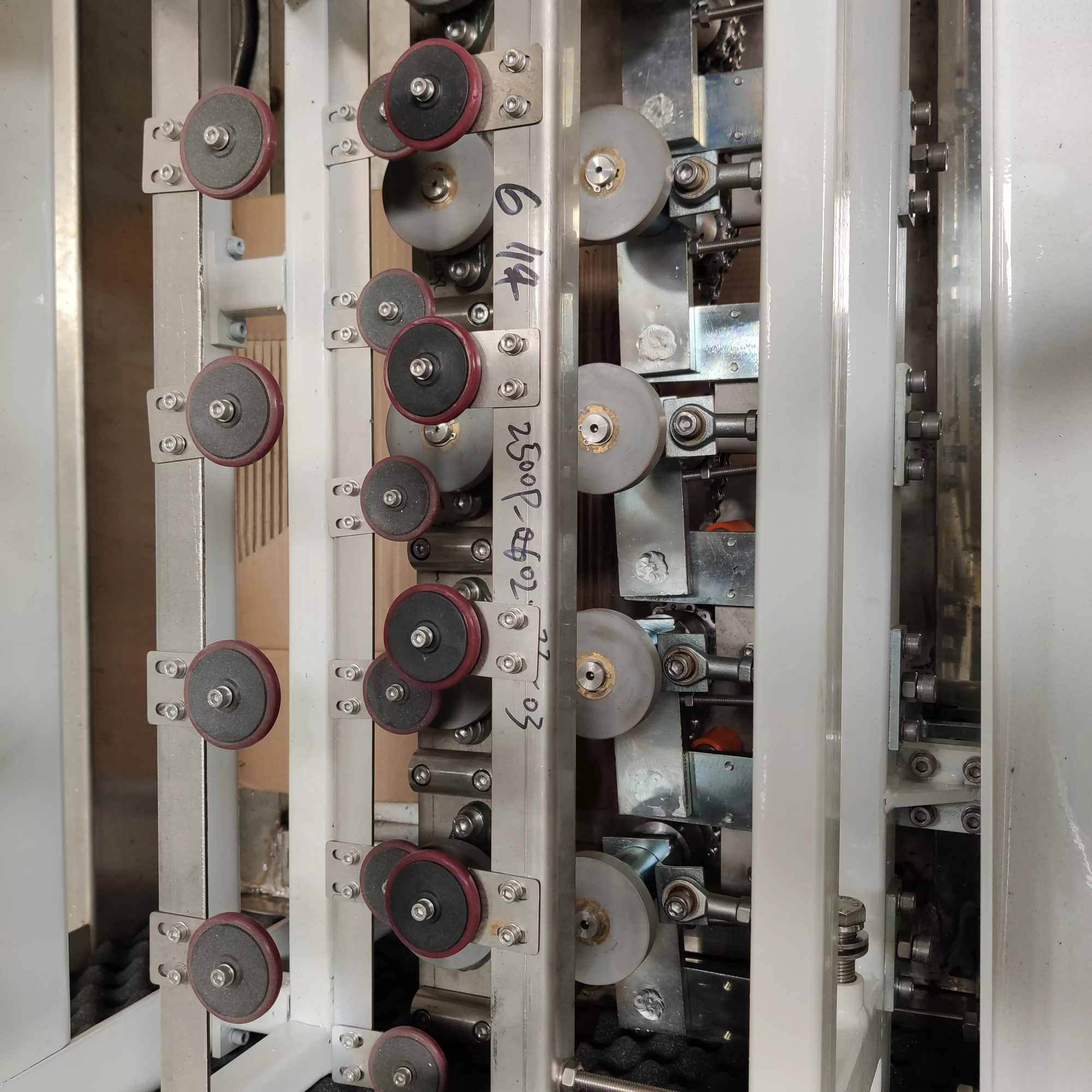

- Automatic tensioning and compression of the transfer roller, automatic adjustment for washing glass of different thicknesses, using waterproof bearings, and parts in contact with water are made of stainless steel, aluminum, or copper, with long service life; there is a piece of soft material scraper on the upper and lower sides of the glass at the end of the washing section The water plate and the glass pass between the two wiper blades.

- Washing water can be recycled. The water tank has a water heating device that can heat the water. Use water with a temperature of about 50°C to wash the glass for better results.

- The unique air knife design uses a pair of stainless steel inclined air knives made by CNC bending technology to form a high-pressure air filter. The pressurized air is connected to the air knife edge through the hose, and the dry air is blown from the air knife edge at an optimal angle. The glass pieces are washing and the drying effect is good.

- Inside the blower, the drying section is equipped with sound-absorbing materials.

Figure 1 LJLQ-2500 vertical glass washing and drying machine 1

Figure 1 LJLQ-2500 vertical glass washing and drying machine 1

Equipment Advantages

LJLQ-2500 glass washing machine can wash max glass of 2500 mm*3500 mm, more large size and less size can be optional.

- Self-Diagnosis system with touch screen on computer.

- Fully corrosion-resistant materials, including the air knife and brush roller are made of stainless steel.

- Stainless steel washer with 8 ( could optional 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input.

- Rotate speed of brush frequency control. (optional)

- Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19 mm.

- High speed washing ( max 14 m/min), Low noise ( max 70 dB), high availability working. (25 second /unit)

- Automatic detection of Low-E glass and alarm for coating in reverse. (optional)

- Structure stepped and three-layer insulating glass unit available. (optional)

- Precision of plate press: ±0.3mm.

- Two relatively independent water tanks. Water can only flow from the rear water tank to the front water tank.

The water tank is equipped with a heater; 3 pairs of brushes (high-temperature wire) and four pairs of water spray pipe structures. The water channels of each brush are sealed to prevent the washing machine from being damaged. Internal sputter contamination.

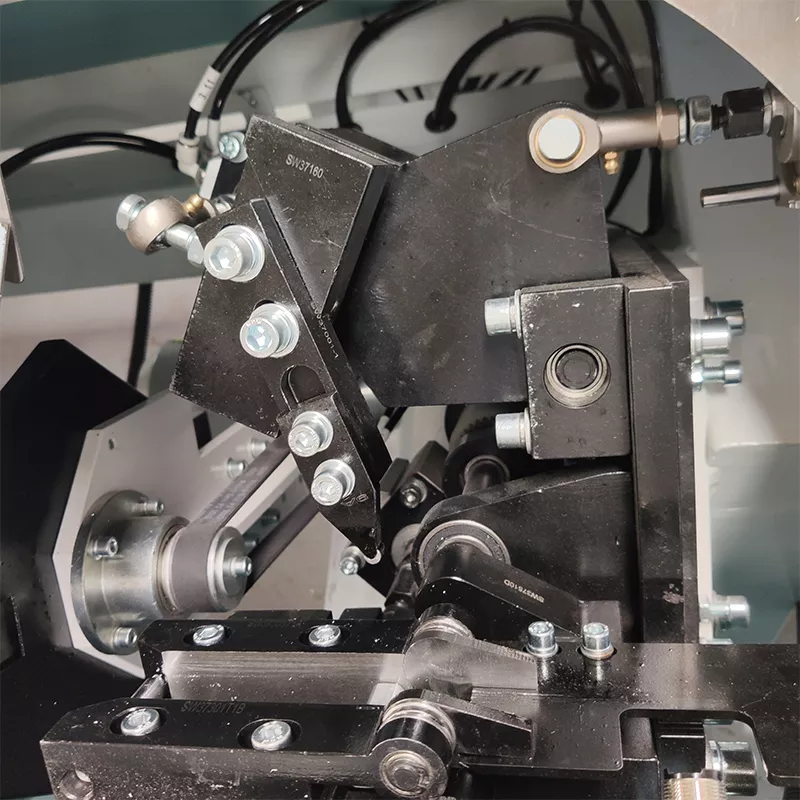

Figure 2 LJLQ-2500 vertical glass washing and drying machine 2

Figure 2 LJLQ-2500 vertical glass washing and drying machine 2

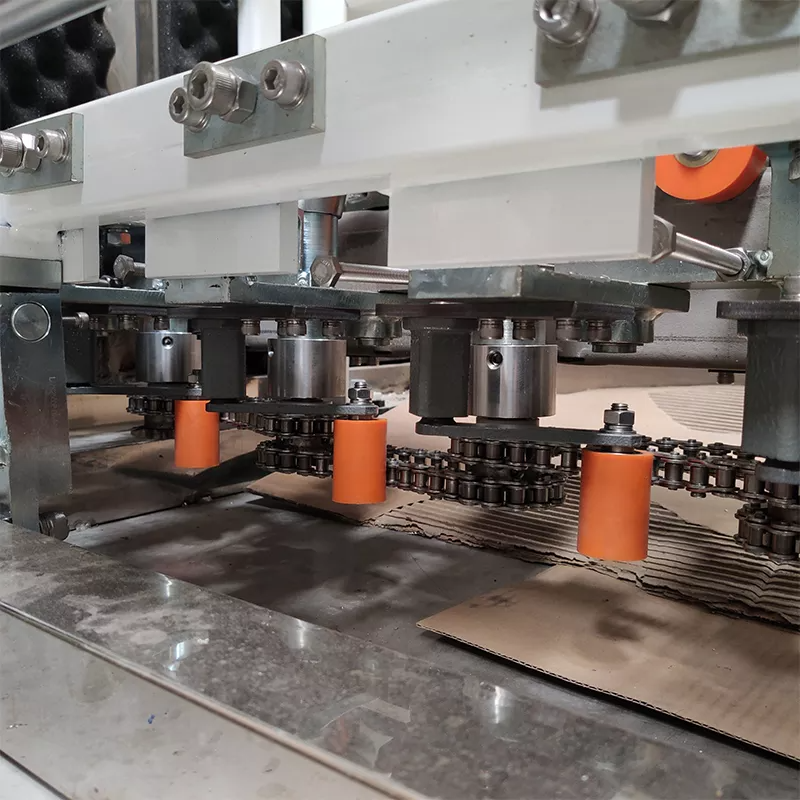

Figure 3 LJLQ-2500 vertical glass washing and drying machine 3

Figure 3 LJLQ-2500 vertical glass washing and drying machine 3

Figure 4 LJLQ-2500 vertical glass washing and drying machine 4

Figure 4 LJLQ-2500 vertical glass washing and drying machine 4

Figure 5 LJLQ-2500 vertical glass washing and drying machine 5

Figure 5 LJLQ-2500 vertical glass washing and drying machine 5

Figure 6 LJLQ-2500 vertical glass washing and drying machine 6

Figure 6 LJLQ-2500 vertical glass washing and drying machine 6

Figure 7 LJLQ-2500 vertical glass washing and drying machine 7

Figure 7 LJLQ-2500 vertical glass washing and drying machine 7

Advantages & Benefits

☆The glass washing machine could wash ordinary flat glass or coated glass with a thickness of 3~12mm;

☆The washing area uses 3 pairs of brushes or optional 4 pairs of brushes (or imported soft brushes, coating or Low-E Glass special), two or four water cleaning;

☆The machine adopts an inclined vertical structure, the flat glass is placed on the conveyor roller, passes through the feeding section, cleaning and drying section, and reaching the discharging section to complete the glass cleaning task;

☆The washing area and the water tank are made of stainless steel and corrosion-resistant materials; the inclined wind knife with strong wind can dry the glass surface;

☆The discharge section is equipped with inspection lamps to check the cleaning quality of the glass. The machine is easy to operate, and the operation buttons are concentrated on the operating table.

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180mm + four sprays, the glass is cleaned and the speed is fast (10-12m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the washing box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Frequently Asked Questions of Automatic Glass Washing and Drying Machine

When using a glass washing and drying machine, sometimes the glass may not be cleaned cleanly. This is due to the following reasons:

1.1 Insufficient washing time: It may be that the washing time is set too short or the machine washing efficiency is not high. It is recommended to increase the cleaning time or replace the equipment with more efficient equipment.

1.2 The temperature of the washing water is too low: The temperature of the washing water is not high enough, which can easily lead to incomplete washing. It is recommended to increase the temperature of the washing water appropriately.

1.3 Improper proportion of cleaning agent: Improper proportion of cleaning agent will also lead to incomplete cleaning. It is recommended to configure the proportion according to the instructions for the use of the cleaning agent.

2. The washing machine makes a noise

When using the glass washing and drying machine, sometimes the glass washing and drying machine will make a noise. There may be several reasons:

2.1 Aging of glass washing machine: The glass washing machine equipment has been used for too long, resulting in aging of parts and noise in the glass washing machine. It is recommended to replace the glass washing machine equipment in time.

2.2 Loose parts: During the use of the glass washing machine equipment, parts may become loose, causing the glass washing machine to make noise. It is recommended to check whether the parts of the glass washing machine equipment are loose and tighten them in time.

2.3 Insufficient glass washing fluid volume: Insufficient glass washing fluid volume will also cause noise in the glass washing machine. It is recommended to increase the amount of glass washing fluid added.

3. Poor drainage

When using a glass washing machine, sometimes there will be poor drainage. The following reasons may occur:

3.1 The drainage holes are blocked: During the use of the glass washing machine equipment, the drainage holes are easily blocked by dirt, resulting in poor drainage. It is recommended to clean the drainage holes regularly.

3.2 Water pump failure: Water pump failure can also cause poor drainage. It is recommended to check whether the water pump of the glass washing machine equipment is normal.

3.3 Drainage pipe problems: Problems with the drainage pipes can also lead to poor drainage. It is recommended to check whether the drainage pipes of the glass washing machine equipment are smooth.

The above is an analysis of common abnormalities and causes of glass washing machines. It is recommended that you carefully understand how to use the glass washing machine before using it, use it in strict accordance with the instructions in the instructions, pay attention to the maintenance of the glass washing machine equipment, and replace seriously worn parts promptly.

What are the common failures of automatic vertical glass washing and drying equipment?

If the glass washing brush in the glass washing and drying equipment jumps or makes abnormal sounds, you can check the chain and bearings. The cause of this failure is usually a loose chain or damaged bearings, so you need to check these two parts. If the chain is loose It needs to be tightened and reinforced. If the bearing is damaged, the bearing needs to be replaced.

2. The transmission shaft is suddenly fast and sometimes slow

Under normal circumstances, the transmission shaft of the glass washing and drying equipment should have a stable speed. If the speed is unstable and the speed is fast and slow, there may be a problem with the speed regulator, or the chain may be loose. After inspection by the equipment operator, if the problem is with the chain, it can be tightened. However, if the problem is with the speed regulator, professional after-sales maintenance technicians should be found for adjustment.

3. Glass shifts or breaks

The glass should not shift or even break during glass washing. However, if such a problem occurs, it means that the glass washing and drying equipment is faulty. The uneven force on both ends of the pressure roller of the equipment will cause the glass to shift. The pressure should be adjusted. The roller is adjusted to a state of balanced force. The glass is broken because the bearing of the brush is damaged and the pressure roller cannot press the glass, so targeted inspection and repair are required.