Automatic Three-Axis Waterjet Glass Cutting Machine

LIJIANG Glass automatic waterjet glass cutting machine is a plane cutting machine tool that combines an ultra-high-pressure water jet generator and a two-dimensional CNC machining platform. It raises the pressure of the water flow to a high enough level (above 200MPa) so that the water flow has great kinetic energy. By mixing a certain proportion of abrasives in the high-speed water flow, it can penetrate almost all hard materials such as glass.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

2515/3020/4020/6030 Automatic Waterjet Glass Cutting Machine

Water jet cutting is a device that uses ultra-high-pressure water jets for cold cutting. It mainly consists of a high-pressure pump, a CNC machining platform, and a jet-cutting head.

The water jet cutting machine is a plane cutting machine tool that combines an ultra-high-pressure water jet generator and a two-dimensional CNC machining platform. It raises the pressure of the water flow to a high enough level (above 200MPa) so that the water flow has great kinetic energy. By mixing a certain proportion of abrasives in the high-speed water flow, it can penetrate almost all hard materials such as glass. Under the guidance of the two-dimensional CNC machining platform, processing can be started or ended at any position on the material, and the machine can move at an appropriate speed according to the set trajectory to achieve plane cutting processing of arbitrary graphics.

A set of CNC waterjet cutting machines (referred to as "waterjet") consists of three parts: ultra-high-pressure water jet generator (high-pressure pump), CNC processing platform, and jet cutting head.

Figure 1 Automatic Waterjet Glass Cutting Machine 1

Figure 1 Automatic Waterjet Glass Cutting Machine 1

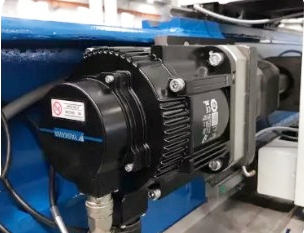

1. Ultra-high-pressure water jet generator (high-pressure pump)

As the power source of water jets, a common technical solution is a hydraulic motor driving a supercharger to generate ultra-high-pressure water jets. The pressure of ordinary tap water is increased to tens to hundreds of MPa (1MPa is approximately equal to 10 bar), and it is ejected through a beam nozzle with extremely high kinetic energy.

Figure 2 The water jet generator (high-pressure pump)

Figure 2 The water jet generator (high-pressure pump)

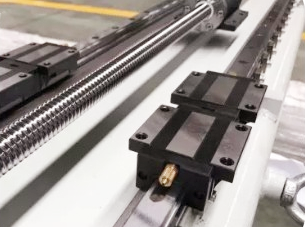

2. CNC machining platform

CNC water jets are mainly used to cut flat plates. The cutting platform uses rolling linear guides and ball screws as transmission. Under the precise control of CNC programs and control motors, the X-axis and Y-axis can accurately move independently or in conjunction with each other, driving the cutting head to achieve straight-line and arbitrary curve cutting.

Figure 3 The CNC machining and finishing platform

Figure 3 The CNC machining and finishing platform

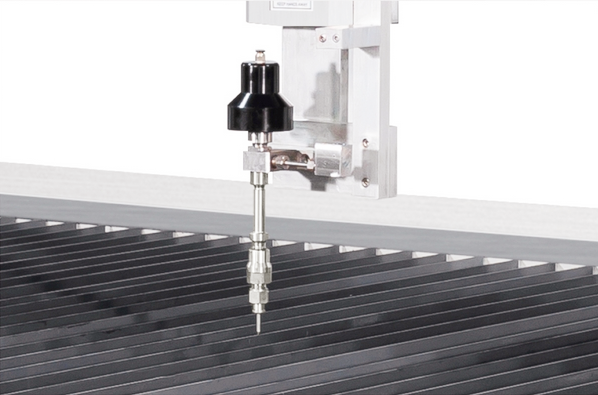

3. Waterjet cutting head

The high-pressure pump can only achieve the cutting function through the beam nozzle. The size of the nozzle hole determines the pressure and flow rate. At the same time, the nozzle also has an energy-gathering effect. There are two basic forms of jet cutting heads: one for pure water cutting, and one for abrasive cutting. The cutting head containing abrasive cutting is based on the pure water cutting head, plus an abrasive mixing chamber and a hard nozzle.

Figure 5 The Imported Ball Screw and Linear Guide 1

Figure 5 The Imported Ball Screw and Linear Guide 1

Figure 6 The high speed servo motor 1

Figure 6 The high speed servo motor 1

Figure 7 Automatic sand feeding system 1

Figure 7 Automatic sand feeding system 1

- The omni-directional cutting function could be used for arbitrary curve cutting.

- The cutting head is equiped with a reliable pneumatic high-pressure water switch control device to improve production efficiency.

- All stainless steel protective cover, dustproof, waterproof, antirust, anticorrosion, easy to water washing to keep the cutting platform as bright as new.

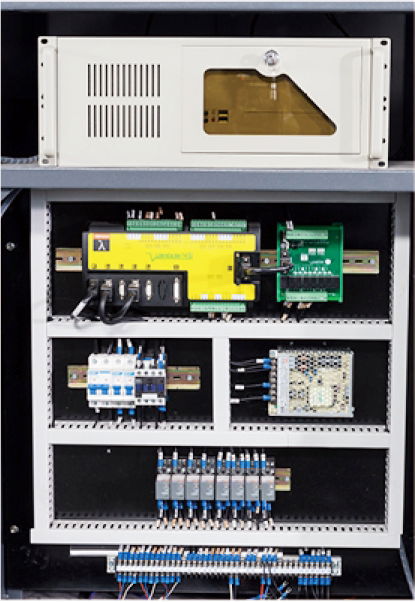

Figure 9 Clear wiring in power distribution cabinets 1

Figure 9 Clear wiring in power distribution cabinets 1

- Using professional industrial computer, with good anti-interference effect and stability.

- Full Auto CAD DWG format support, automatically control code generation from DWG files.

- Simulation runs could be used to double check for cutting error.

- Auto lead-in and lead-out, corner slow down cutting, compensation increase production effect and cutting quality.

Technical Parameters

| Machine type | 2515 | 3020 | 4020 | 6030 |

| Dimension(mm) | 3400*2650 | 3900*3050 | 4900*3050 | 6950*4050 |

| Max. cutting range(mm) | 2500*1500 | 3000*2000 | 4000*2000 | 6000*3000 |

| Travel of Z axis | 150mm | |||

| Control accuracy | ±0.01mm | |||

| Cutting accuracy | ±0.1mm | |||

| Re-positioning accuracy | ±0.025mm/m | |||

| Max. moving speed | 6000mm/min | |||

How does the water jet cutting machine operate?

When cutting materials less than 2.5 mm thick, using a medium or large cutting head is not very productive. If necessary, use small parameter combinations and consider multi-head cutting to increase yields.

2. Underwater cutting

Underwater cutting can reduce surface or upper-edge fogging caused by abrasive water jet cutting. Underwater cutting can greatly reduce the noise during cutting and make the working environment more tidy and orderly.

3. Smaller abrasive mesh size

A smaller abrasive mesh will reduce the speed slightly but will produce a smoother surface.

4. Encountering air gaps during cutting

Avoid cutting air gaps larger than 0.5mm. The nozzle tends to diverge in the air gap, resulting in a rough surface when cutting low layers. When stacking and cutting, keep the sheets neatly stacked together.

5. Automatic loading and unloading.

Most machines do not use automatic loading and unloading technology, such as shuttle machines.

6. Increase or decrease the water pressure through the controller.

7. Ordinary tap water.

The water jet system uses ordinary tap water. 90% of pure water and abrasive waterjet users require only that the water be softened before passing through the pump inlet filter and entering the booster. Reverse osmosis and deionization technologies can greatly extend the life of the nozzle while causing expensive damage to the booster and high-pressure lines.

8. Control systems specially designed

Control systems specially designed for a process are usually more efficient and easier to use than general multi-process control.