Fully Automatic Horizontal Glass Four-sided Linear Edge Grinding Machine

A fully automatic horizontal glass four-sided linear edger is a professional processing machinery and equipment for chamfering rectangular original glass. It is suitable for processing insulating glass for buildings, doors, and windows, as well as clear glass and Low-E glass with complex and single specifications. It has the overall characteristics of high processing precision, high efficiency, and high mechanical configuration. The environmental protection design concept adopts man-machine interface operation, four-axis linkage, automatic identification of glass size; and glass of different specifications and thicknesses can be loaded continuously, without manual adjustment and waiting, with belt-type vacuum suction transmission and fixed glass after processing edging and film removal, effectively avoiding glass scratches and surface indentations, improving glass processing speed and reducing processing costs.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

Fully Automatic Horizontal Glass Four-sided Linear Edge Grinding and Polishing Machine

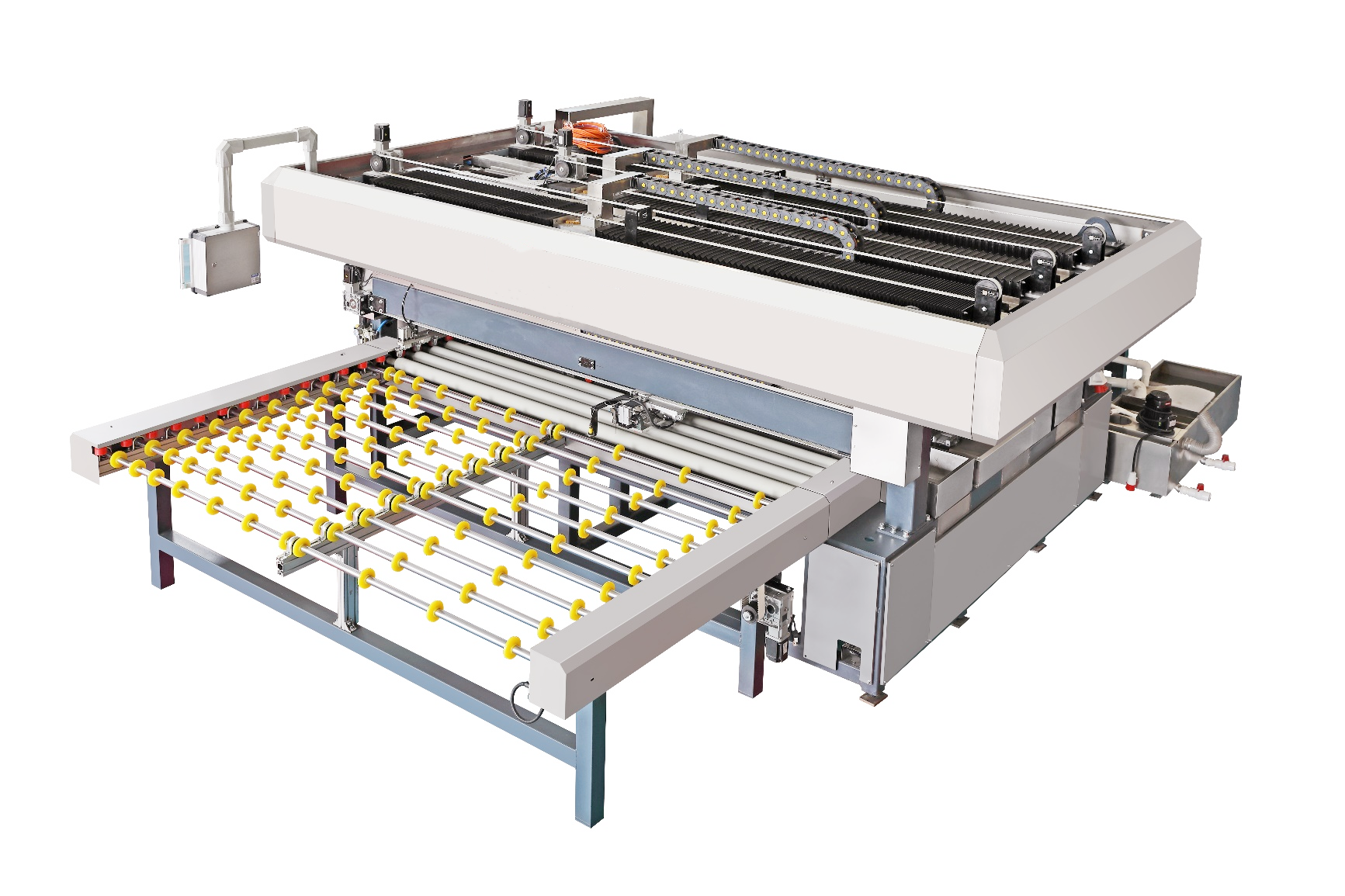

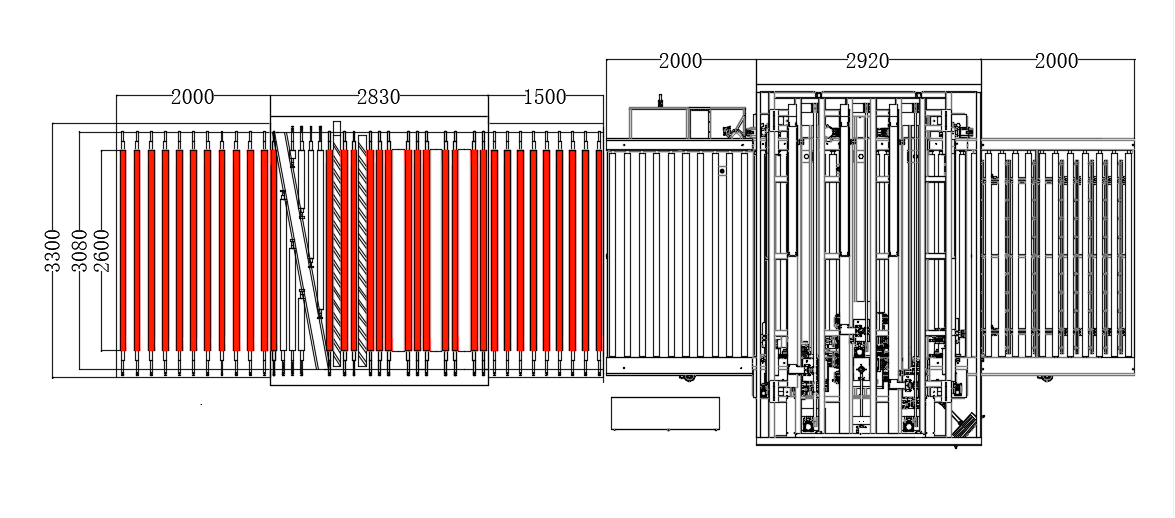

The fully automatic horizontal glass four-sided linear edging machine is divided into three parts: the film entry table, the edge grinding frame, and the film discharge table. The film entry table and film exit table are used in conjunction with the edge grinding frame to grind glass. The edge grinding stand has 2 sets of grinding heads. Each group of grinding heads has two grinding wheels. The edging process is simple, first grind the head of the glass, then rotate the grinding head 90 degrees, cooperate with the grinding wheel on the side to grind the two sides of the glass, and then rotate the grinding head 90 degrees again to grind the tail of the glass, complete the entire edge grinding process. After grinding, the rotation returns to zero and waits for the next piece of glass to be ground. The craftsmanship is smooth and natural, and the fit is tight. It compresses the edge grinding time to the maximum extent and greatly increases the speed of glass edge grinding.

Fully automatic horizontal glass four-sided linear edging machine 1

Fully automatic horizontal glass four-sided linear edging machine 1

Benefits and Advantages

PLC is used to control the manual interface operation, and the 12-axis servo motor control system can choose three working modes with different functions (including chamfering, edge grinding, and film removal). The processing speed of edges and corners can reach 25 m/min. When grinding the bottom edge at the same time, the speed is 20 m/min. The glass size can be automatically identified efficiently without manual input of the glass size. Glasses of different specifications can be loaded continuously. The work efficiency is high. It is an efficient, energy-saving, and automatic grinding machine. Edge processing equipment, in terms of specific energy saving, includes electricity cost, water cost, grinding wheel cost, human resource cost, and space-saving. It can be combined with cutting lines, automatic loading and unloading tables, cleaning machines, tempering furnaces, and other equipment to form a fully automatic system. The glass processing unit is the most powerful supporting equipment for edge grinding processing of building insulating glass, curtain wall glass, door and window glass, laminated glass, and other categories.

Main structure of automatic glass seaming machine

Main structure of automatic glass seaming machine

(3 crossbeams, 4 grinding heads)

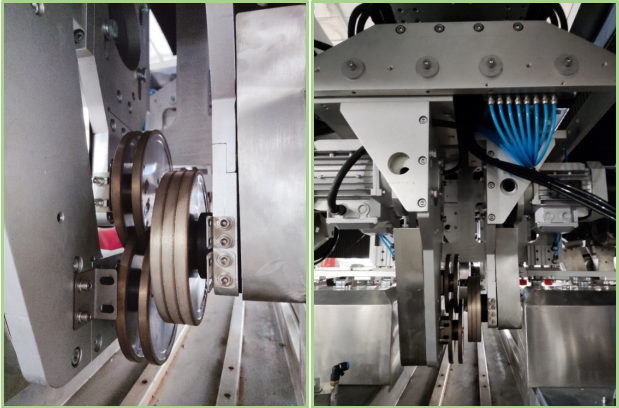

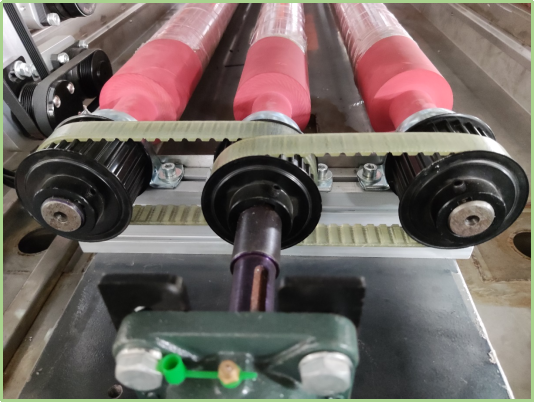

Synchronous belt transmission: Little distance, no swing, high precision of transmission

Synchronous belt transmission: Little distance, no swing, high precision of transmission

IGrinding head structure: Arris + base grinding wheel. Aluminum alloy metal part.

IGrinding head structure: Arris + base grinding wheel. Aluminum alloy metal part.

Feed in section: Universal wheel with cylinder lifting, rubber roller conveyor, aluminum alloy support bar, side bar

Feed in section: Universal wheel with cylinder lifting, rubber roller conveyor, aluminum alloy support bar, side bar

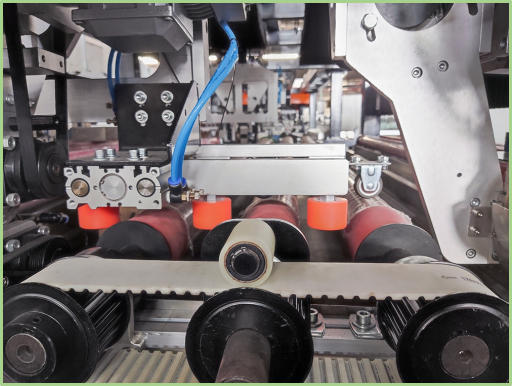

Roller side transmission structure: Double belt, firm structure without slipping.

Roller side transmission structure: Double belt, firm structure without slipping.

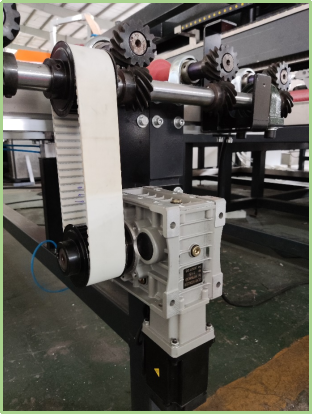

IRoller main transmission structure: Synchronous belt with reducer

IRoller main transmission structure: Synchronous belt with reducer

Equipment Configuration

| Item. | Spec. |

| Main machine frame | Strong welding annealing steel, no deformation. |

| Grinding wheels motor | Triple-phase asynchronous motor |

| Linear rail | Taiwan Hiwin |

| Pneumatic elements | Taiwan Airtac |

| Photoelectric switch | Germany Pepperl+Fuchs |

| HMI | Beijing Kunluntongtai MCGS 10.1 inch |

| Control system(PLC / CPU) | Shenzhen Gugao |

| Servo motor | Shenzhen Motong |

| Rotary switch, emergency stop | Chint |

Contractor, thermal relay | Schneider |

| Transformer | Tengen |

| Low pressure breaker | Schneider |

Work Efficiency

| Arris width size range | Grind speed | 1000mm*1000mm(pcs/h) | 2000mm*2000mm(pcs/h) | 1555mm*520mm(pcs/h) | |

| Arris only | 0.8~1mm | 35 | 300 | 180 | 220 |

| 1~1.5mm | 30 | 270 | 160 | 180 | |

| 1.5~2.5mm | 25 | 240 | 100 | 110 | |

| Arris +surface | 0.8~1mm arris width+0.5~1mm surface width | 20~25 | 180~200 | 90~100 | 130~150 |

Spare Parts List

| Item | Name of spare parts | Quality(pcs) |

| 1 | Side wheels | 20 |

| 2 | Pressure wheel | 20 |

| 3 | Transmission belt | 3 |

| 4 | Bearing | 10 |

| 5 | Tool case | 1 |

Fully automatic horizontal glass four-sided linear edging machine 2

Fully automatic horizontal glass four-sided linear edging machine 2

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Why we need the Glass Edge Grinding and Polishing Machine

The edges of glass that were ground by hand in the past were not perfect.

Glass edging machine is used in the modern glass deep processing industry. It is one of the most widely used cold processing machinery and equipment in the production of glass deep processing equipment. It is mainly suitable for the processing of civil glass, architectural glass, and craft glass. The basic function is to smooth glass and make some special-shaped glass materials.

The working principle of the glass edge grinding machine is to grind and polish the edge of the glass through the grinding head motor and grinding wheel. Ordinary single-sided or double-sided edge grinding machines can achieve rough grinding, fine grinding, and polishing in one go. According to different processing requirements, different grinding wheels can be selected.

(The picture below shows the rough grinding and fine grinding produced in the factory)

Four-sided high-speed grinding finished product

High-speed automatic grinding of finished products

Double straight edge finished product

There are many kinds of glass edge grinding machines, with different needs for the deep processing of glass and different functions.

1. Double straight edge grinding machine

The double-straight-edge grinding machine is suitable for grinding double-straight edges of flat glass, rough grinding, and polishing at one time. The grinding head seat slides using double linear rolling guides and double ball screw drive to achieve a stable moving speed, eliminate moving gaps, reduce resistance and wear, and ensure repeated positioning. The PLC control system (i.e., a new generation of industrial control devices formed by introducing microelectronics technology, computer technology, automatic control technology, and communication technology based on traditional sequence controllers) sets processing parameters through the interface to complete processing in one go. The conveyor belt drive adopts variable frequency motor speed control, with constant power and constant torque output, which is stable and reliable. Polishing adopts a pneumatic automatic compensation device. Especially suitable for processing furniture glass and architectural glass.

Large-scale double straight-edge edging machines generally have 16 grinding heads, 20 grinding heads, 26 grinding heads, and 28 grinding heads double straight-edge edging machines. The double-sided edging machines have high processing efficiency, but the price is relatively high, and they are suitable for large-scale Tempered glass factories. Double straight-edge grinding machines, glass transfer tables, glass cleaning machines, and other equipment form a production line, which is also one of the more expensive equipment production lines.

(The picture below shows the connection of our factory’s precision grinding lathe)

Let’s see what it looks like after fine grinding

2. Fully automatic glass four-edge grinding machine

The fully automatic horizontal four-sided glass edging machine is divided into three parts: the film input table, the edge grinding frame cleaning table, and the film output table. The film entry table and film exit table are used in conjunction with the edge grinding frame to grind glass. The edge grinding stand has 2 sets of grinding heads. Each group of grinding heads has two grinding wheels. The edge grinding process is simple. First, grind the head of the glass, then rotate the grinding head 90 degrees, and use the grinding wheel on the side to grind both sides of the glass. After that, the grinding head rotates 90 degrees again to grind the tail of the glass. , complete the entire edge grinding process, and then send it to the cleaning table to air dry. After grinding, the rotation returns to zero and waits for the next piece of glass to be ground. The craftsmanship is smooth and natural, and the fit is tight. Minimize the edging time and greatly increase the speed of glass edging.

3. Fully automatic edge grinding production line

The fully automatic glass edge grinding production line is an advanced and efficient glass processing production line. It is generally composed of two double-edge grinders and a transitional edge turning device and can be formed into a straight line. Fully automatic control, accurate positioning, and high precision, it can complete the grinding of four sides at one time.

How to properly maintain a glass edge grinding machine?

2. When changing the water, please unplug the power plug first and then take out the water tank. After draining the wastewater, clean the scale in the water tank and on the filter.

3. After processing operations, a large amount of foam may be produced in the water tank. A defoaming agent can be added when replacing the processing water, and the foam generated can be eliminated by spraying it 7 to 10 times. When there are particularly many bubbles, you can directly spray 2 to 3 times at the bubbles, and the effect will be better after stirring.

4. Clean the water nozzle. Once the water spray port is clogged, the water volume will be reduced or there will be no water, resulting in reduced processing capacity or even failure to work. When cleaning the water nozzle, please unplug the nozzle and use a fine needle to clear the blockage inside the nozzle.

5. Clean the waterproof cover of the edger. Working for a long time will cause cutting dust to adhere to the waterproof cover. If not cleaned in time, the cutting dust will solidify and be difficult to remove. Thereby affecting the observation line of sight. After daily processing, it needs to be cleaned with brushes and water spray containers.

6. Clean the edge grinding room. Long-term processing will cause cutting dust to adhere to the clamp shaft, chuck, and the wall of the grinding chamber. If not removed in time, it will scratch the lens. It will also cause the clamp shaft sealing ring to wear and cause water to enter the machine head.

There are two cleaning methods:

(1) Clean directly with a brush and water spray container.

(2) Enter the machine cleaning mode for cleaning. This method can also clean the water supply pipeline inside the machine.

7. Clean the edge grinder and scanner housing. The machine must be cleaned immediately after use every day. Otherwise, the cutting powder will solidify on the casing and be difficult to remove. When cleaning, please use a soft cloth dipped in neutral detergent to clean the casing.

8. Dress the grinding wheel. When the grinding wheel is dull, the processing time becomes longer, so the grinding wheel should be repaired in time.