What is the Safety Glass: More Application in Traffic Areas.

1. The introduction

One has the impression that awareness of building safety has increased in recent years. However, there is still a lot of ambiguity regarding the use of safety glass in traffic areas.

2. The safety glass - what exactly is it?

In the field of flat glass, there are various glass types. The basic product is float glass, which is almost completely flat and has the best optical quality, but the lowest strength. Glass can break due to tiny surface cracks and defects, which expand rapidly under tensile stress - float glass is very dangerous when it breaks. However, by pretreatment, stresses can be applied in the glass, which can influence its shattering pattern.

For example, ESG (tempered single-layer safety glass) is a heat-treated glass that cools relatively quickly, so that some of the prestress in the glass is "frozen". As the name suggests, it breaks into small, blunt, "safe" fragments with a low risk of injury. ESG can already achieve a certain degree of damage resistance as a single-layer glass. However, since the fragments are still interlocked, they can become dangerous in the form of large fragments if they fall from a greater height (e.g. 4 m>). However, one disadvantage of ESG is that nickel sulfide inclusions (NiS) can cause spontaneous shattering of the glass. Unfortunately, there is currently no way to prevent NiS components from entering the glass furnace during float glass production and causing contamination.

In the case of broken glass alone, there is no residual load-bearing capacity. However, the residual load-bearing properties can be improved by connecting multiple glass sheets, such as laminated glass (VG). This is a composite of a glass sheet and one or more other glass sheets. A suitable interlayer made of plastic forms the composite. Laminated tempered glass (VSG) is a laminated glass in which, in the event of shattering, the interlayer retains the glass fragments and limits the opening size. This provides a certain residual load-bearing capacity and reduces the risk of cuts and punctures.

In summary, safety glass refers to glass with safe shattering properties. These include tempered safety glass (ESG), homogeneous tempered glass (ESG-H), laminated tempered glass made of float glass (VSG), VSG made of ESG, VSG made of ESG-H and VSG made of partially tempered glass (TVG), which are considered to have safe shattering properties.

3. The requirements and solutions

There are uniform product standards for doors and gates in Europe, at least for outdoor access doors. As far as glass is concerned, there is only one thing to note, that is, the glass components must be designed in such a way that they do not constitute a hazard under normal operating conditions, or correspondingly safe glass must be used.

In Germany, we have also had general building regulations covering access safety for many years, as well as recognized technical rules, such as the current version of DIN 18008 in 2020. In this version, the building regulations have been concretized as far as glass in the construction industry is concerned:

"If protective measures for the glass are required due to legal requirements for access safety, this can be met by restricting access (barriers) or by using glass with safe shattering properties."

However, when does it become necessary to use which glass in which building product?

In 1957, architectural expert Obering.E.Haselberger mentioned in an article published in his professional journal: "In busy places, people rush around and children push and bump into each other, and safety hazards follow. These places should use proven laminated tempered glass to seal building components. It is a risk-free choice."

Figure 1 Glass door in Munich Airport

It is impossible to generalize which glass should be used in which building products, but there are some guiding suggestions that can help: For example, for the use of glass in doors and gates, the document "Safety of Glass Doors and Floor-to-ceiling Glass" (as of October 2019) jointly issued by ift Rosenheim, the German Federal Flat Glass Association (BF) and the Window and Curtain Wall Federation (VFF) provides relevant guidance.

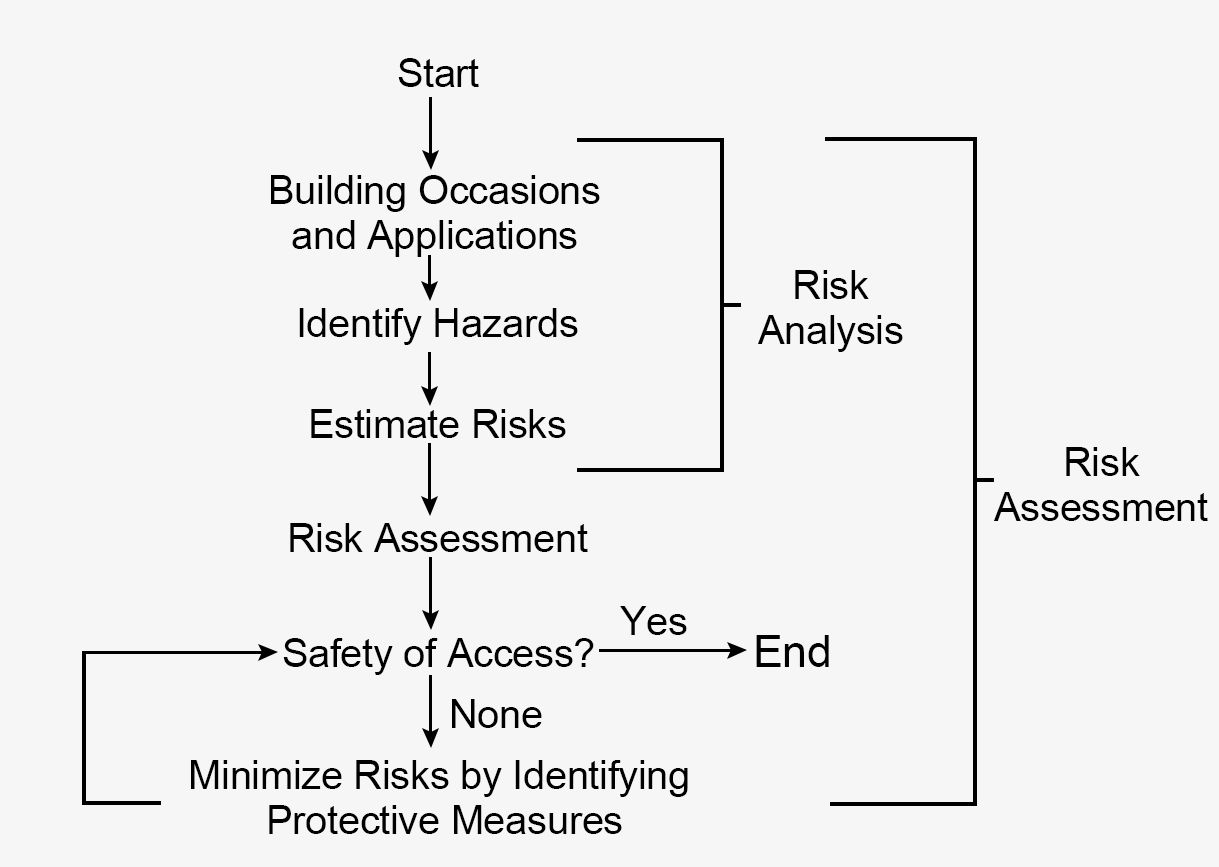

Figure 2 Procedure for risk assessment of access safety

(Source: "Access safety in glass doors and floor-to-ceiling glass without fall protection" - BF, October 2019)

This document contains the procedure for assessing access safety risks, distinguishing between "very low probability of glass breakage" and "high probability of glass breakage".

Very low probability of glass breakage means:

- Clear opening size of insulating glass ≤ 300mm or ≤ 0.2m², or single-layer glass ≤ 200mm

- Floor-to-ceiling windows outside the sidewalk (e.g. behind fixed furniture)

- Balcony doors with a short distance in front of or behind the glass window

- Uncommon rooms (e.g. storage rooms, cellars)

High probability of glass breakage includes:

- Glass in the direction of the sidewalk

- Opening sashes extending into the walkway

- Glass doors and full-glass doors with injury risk

- Glass partitions

- Glass outside the entrance and passage areas

In addition to using safety Glass with full shatter characteristics (minimizing damage), also involves other protective measures:

- Applying protective film

- Setting up barriers, such as steps or platforms, determined by height (≥200mm) and depth (≥200mm)

- Installing crosspieces and front frames

- Setting up railings

- Placing radiators in front of the glass

- Green protection strips

- Setting up window sills or beams in front of the glass

- Guiding or restricting the use of people

- Specially marking movable facilities that block access in front of the window (e.g. by stickers, printing or embossing)

For further help, see the BF's "Information on safety glass in the new DIN 18008". The VFF's document V.05–2020-03 "Recommendations for the use of safety glass in the construction industry" provides specific usage recommendations in the form of tables and was prepared in cooperation with the BF, the glass industry BIV, ift Rosenheim, Tischler Schreiner Deutschland and UBF.

4. The conclusion

It is not possible to give a general answer to which glass should be installed in which building product and in which door. Some auxiliary materials can help, such as various manuals and recommendations compiled by independent associations. At the same time, the level of technology is also a factor to consider.

Ultimately, designers, architects and owners must determine which glass ensures the safety of the traffic area. Although there is no explicit requirement to use safety glass, this does not mean that float glass can meet all needs.

Author

Carolin Lamprecht, ift Rosenheim

References

[1] BF-Information 016 / 2020 – Änderungsindex 0 – April 2020

Information on glass in the new DIN 18008 – Glass is the glass of the Flachglas Bundesverband e. V, Troisdorf

[2] VFF-Merkblatt V.05 “Einsatzempfehlungen for glass in Bauwesen“ Verband Fenster + Fassade, Frankfurt 2020