The cutting and edge bending quality control of ultra-thick and ultra-long float glass.

Ultra-thick float glass is widely used in museums, car 4S stores, hotel ground floors, high-end display windows, airports, and sports venues. Due to the particularity of the use field, ultra-thick glass is mostly presented in ultra-large and ultra-long large-sized forms. Due to the difficulty of actual manufacturing, it has become a high-value product. Since ultra-thick glass is mostly 7000mm and above ultra-long and large-sized products, the edge cutting and stripping lines are long, so the key points of its edge quality control are mainly reflected in the edge bending link. If it is not properly controlled, it will bring two hidden dangers: one is safety hazards. If the edge is jagged, the cross-section is concave and convex, or small cracks appear, there may be risks of splinters in the warehouse or during transportation. The second is poor processability. Smooth edges can improve the utilization rate of glass and reduce the difficulty of processing. Therefore, a soft and regular cutting section can not only reduce the loss of cutting fragments, improve the safety of storage and transportation of large-sized glass products, and improve the processability of products, but also make the glass look more refined and more beautiful overall. It is also a reflection of the technical capabilities of the production line.

1. The principle of float glass cutting

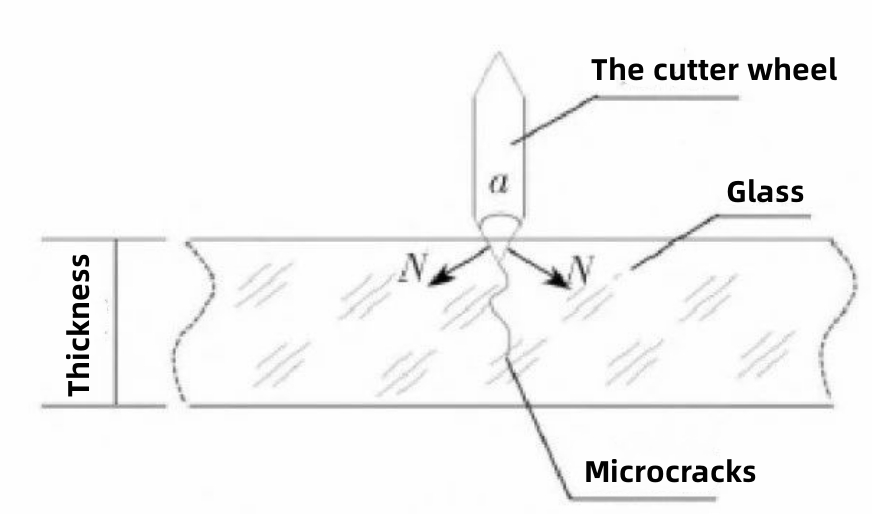

Float glass online cutting generally uses carbide cutter wheels, polycrystalline diamond cutter wheels, etc., fixes the blade on the cutter holder, and transmits pressure through the solenoid valve to achieve online glass cutting. The cutting wheel is pressed on the glass surface under a certain pressure. When the pressure at the pressure contact position is greater than the strength of the glass surface, a tiny crack will be generated on the glass surface. When the cutter wheel rolls on the glass surface, the crack continues to expand under and in front of the cutter wheel, forming a continuous cutting crack, that is, the cutting line, as shown in Figure 1.

Figure 1 The schematic diagram of glass cutting

The knife wheel presses on the crack, wedge-pressing the crack expansion. The depth of the knife wheel's cutting is usually between several hundred and one thousand microns (the depth depends on many factors, including input pressure, knife wheel material, shape, blade size, and quality, cutting speed, etc.). In the subsequent breaking process, under the action of external force, the upper surface of the glass at the cutting line is subjected to a large tensile stress, which causes the cutting crack to quickly expand through the entire glass thickness, thereby breaking the glass plate. While completing the above-mentioned cutting process, the knife wheel also has some adverse effects on the glass surface. The contact stress applied by the knife wheel on the glass surface creates a micro-damage area on the glass surface with a depth ranging from tens to hundreds of microns, producing tiny debris. This debris sometimes appears in the form of larger fragments on the edge of the glass, affecting the cutting quality. In mild cases, the surface of the glass section is not smooth, and in severe cases, it forms a jagged shape, or there are obvious small cracks on the section. In severe cases, the glass is broken in fragments during transportation, storage, or transportation.

Excellent cutting should be continuous and without flying chips (i.e. no fragments are generated on both sides of the cut), which can make the glass crack along the cutting line under a small breaking force. Many factors affect the cutting quality, such as glass composition, chemical uniformity of glass, stress relief during glass annealing, etc., but the angle of the cutting wheel and the matching of the size of the cutting pressure with the glass thickness also greatly affect the cutting quality of the glass. The same cutting line depth has different weakening effects on the local strength of a glass of various thicknesses. The thicker the glass, the less the weakening effect of the cutting line on the glass's strength. Therefore, ultra-thick glass requires greater cutting pressure and depth of pressing into the glass, and its cutting is more difficult.

2. The force analysis and selection principles of the cutting wheel

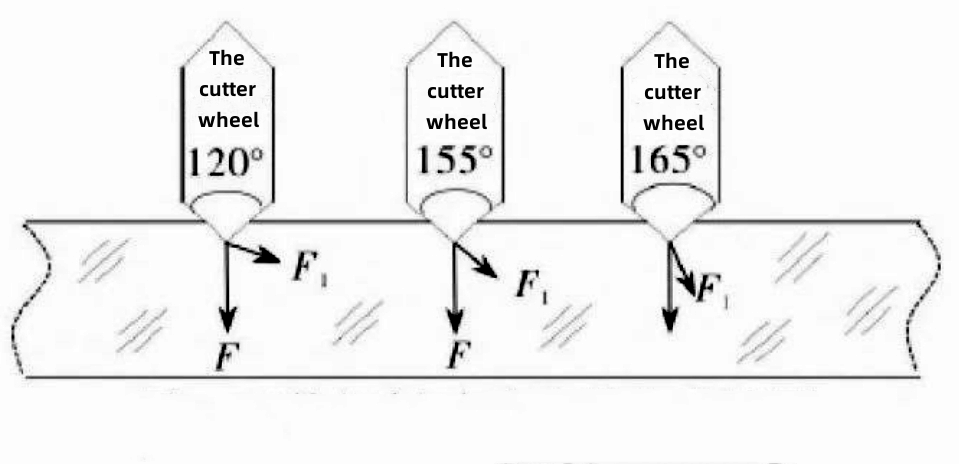

The cutting wheel angle refers to the angle between the two inclined surfaces of the wheel. Glass of different thicknesses uses cutting wheels of different angles. The stress generated by the cutting wheel inside the glass is mainly: downward pressure F and component force F1 perpendicular to the angle of the wheel, as shown in Figure 2.

Figure 2 The analysis of glass force during knife wheel cutting

The downward pressure F is the compressive stress required for cutting, and the force component F1 perpendicular to the angle of the knife wheel affects the cutting quality. Due to the influence of the knife on the edge breaking quality: unreasonable stress distribution will cause the glass to have sawtooth, concave and convex edges, bevel edges, small cracks, and even breakage or fragmentation when cutting and breaking the edge.

Impact on cutting performance: unreasonable stress distribution will make the cutting process more difficult, stress will dominate the fracture path, and the glass cracks will follow the direction of stress distribution, thereby affecting the accuracy and stability of cutting. When the stress is too large, the glass fracture does not follow the cutting line, resulting in incomplete cutting or failure to perform normal cutting. The direction and size of F1 acting on the inside of the glass are different for different wheel angles.

The lateral force component F1 generated by the small-angle cutting knife wheel is large and unfavorable to cutting. If a small-angle cutter wheel is used for cutting when producing thick glass, when the cutting pressure increases to a certain extent, the lateral force will scrape the glass, and a large amount of broken glass will be generated on both sides of the cutter wheel, thereby continuously releasing the pressure applied to the cutter wheel, so that the actual downward pressure of the cutter wheel on the glass is very small, and it is impossible to cut out effective and conducive to breaking the cutter marks. Therefore, ultra-thick glass generally uses a large-angle cutter wheel, which can provide more positive pressure and produce less lateral force when pressurized. Therefore, ultra-thick glass of 15mm and above generally uses a cutting cutter wheel of 155°~165°.

The basic principle of selecting a cutter wheel is: to use a small-angle cutter wheel as much as possible while ensuring smooth edge breaking and match the smallest possible cutting pressure to minimize the damage to the glass surface. However, in actual production, due to internal factors such as residual stress in the glass, it is difficult to achieve an ideal cutting state, so reasonable adjustments need to be made according to actual conditions.

3. The brief analysis of stress of ultra-thick glass

3.1 The impact of unreasonable stress distribution on cutting and edge-breaking quality

For ultra-thick glass, it is necessary to pay attention not only to the lateral stress distribution of the glass but also to pay special attention to the stress in the thickness direction of the glass. Unreasonable stress distribution will have a serious impact on the cutting and edge-breaking quality of ultra-thick glass.

Impact on edge breaking quality: unreasonable stress distribution will cause sawtooth, concave and convex edges, bevel edges, small cracks, and even breakage or fragmentation of the glass when cutting and edge breaking.

Impact on cutting performance: unreasonable stress distribution will make the cutting process more difficult, and stress will dominate the fracture path, so that the glass cracks follow the direction of stress distribution, thereby affecting the accuracy and stability of cutting. When the stress is too large, the glass fracture does not follow the cutting line, resulting in incomplete cutting or inability to perform normal cutting.

3.2 Stress distribution of ultra-thick glass

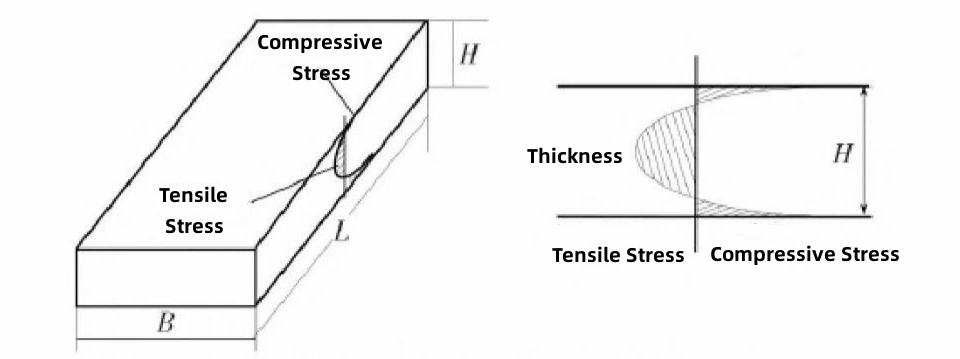

Stress distribution in the thickness direction of ultra-thick glass: Glass is a poor conductor of heat. During annealing and cooling, because the glass surface is always colder than the center when the glass surface temperature drops to room temperature, the glass center temperature is still higher than room temperature. As the center of the glass continues to cool down to room temperature, the surface has stopped shrinking, but the center of the glass will continue to shrink, causing the surface to be in compressive stress, while the center of the glass will be in tensile stress, as shown in Figure 3.

Figure 3 The schematic diagram of stress distribution in the thickness direction of glass

Under the same cooling conditions, the thicker the glass, the greater the temperature difference between the glass surface and the center, and the greater the stress generated. When the value of the tensile stress in the center of the glass is very high, it will cause cutting problems, such as rough surface, sawtooth, etc., that is, when the compressive stress on the upper surface of the glass is relatively high, it will cause the glass not to crack along the cutting line.

Transverse stress distribution of ultra-thick glass: For ultra-thick glass produced by the edge drawing machine method, the thickness of the edge of the glass ribbon (except the edge drawing machine indentation) will be significantly lower than the thickness of the middle part. Therefore, when the ultra-thick glass ribbon enters the annealing furnace, within the same width range, the heat brought into the edge glass ribbon will be much lower than that of the middle glass ribbon. Because the edge glass ribbon is thinner than the middle, its cooling speed will be faster under the same conditions; and because the temperature of the edges on both sides of the annealing furnace is usually lower than that of the middle. Therefore, the edge temperature of the glass ribbon that passes through the annealing furnace and enters the cutting area is lower than that of the middle. Similar to the principle that stress is generated due to temperature differences in the thickness direction of glass, the lateral stress distribution of the glass ribbon is generally in the state of compressive stress at the edge and tensile stress in the middle. If the compressive stress at the edge is too large, it will be difficult to bend the glass edge.

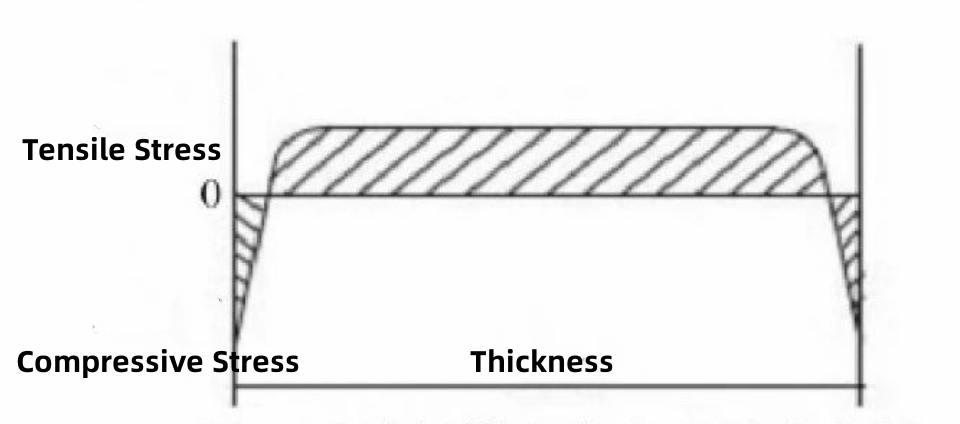

3.3 Ideal stress distribution state of glass

When the annealed glass ribbon reaches the cutting area, temporary stress and some permanent stress remain inside. The magnitude and distribution of stress are directly related to the annealing process. The ideal lateral stress distribution curve of the well-annealed glass ribbon is shown in Figure 4. The ideal stress state of the glass ribbon that is conducive to cutting is that the edge is subjected to a smaller compressive stress and the middle is subjected to a smaller tensile stress. The sum of all compressive stresses is equal to the sum of all tensile stresses. In other words, if the glass edge is under high-pressure stress, then the middle of the glass ribbon will produce high tensile stress. The tensile stress in the middle of the glass is too high, which is not conducive to cutting.

Figure 4 The ideal distribution diagram of transverse stress of glass plate

4. The control of cutting edge of ultra-thick glass

4.1 Parameters of cutting the wall of thick glass

The ultra-thick glass is generally 155° and above angle cutter wheels. For the blade wheel with an angle of 1.00mm or above, the longitudinal cutting direction and cutting pressure adjustment range can be referred to in Table 1.

Table 1 Common cutting parameters for ultra-thick glass

| Glass thickness/mm | Cutting blade stroke/mm | Blade wheel angle/° | Cutting pressure/N |

| 15 | 14.5 | 155~160 | 160~200 |

| 19 | 18.5 | 160~165 | 200~240 |

According to the cutting condition and the actual edge bending condition, it is possible to consider increasing or reducing the pressure appropriately. If there is serious debris on both sides of the blade mark but the edge bending is still not ideal, the blade needs to be replaced; if the new blade wheel has the above phenomenon, the influence of annealing quality should be considered. If the compressive stress on the upper surface of the glass is too large, it is necessary to cool down the inner side of the cutting line in advance (such as adding water to the edge for cooling, etc.), increase the tensile stress at the cutting line to facilitate edge bending and peeling.

4.2 Cutting oil selection

Cutting oil plays a triple role in ultra-thick glass cutting. It protects the cutting wheel and prolongs its service life; it adheres to debris and avoids splashing; and the most important role is to protect the cut marks - through the infiltration and cooling of the cut marks by the cutting oil, the cutting oil continues to penetrate toward the center of the glass along the micro-cracks at the cut marks, not only forming certain tensile stress near the glass surface (in the depth direction) but also reducing the tendency of small defects at the cut marks to expand, which is beneficial to improving the edge bending quality. Therefore, if the evaporation rate of the cutting oil is too fast, it is not conducive to the infiltration and cooling of the cut marks, and it is easy to expand small defects at the cut marks during the edge bending process, thereby affecting the edge bending quality of the glass.

Currently, the commonly used cutting oils are aviation kerosene, glass cutting fluid, cutting agent, etc. From the actual production and long-term use, it is recommended to use glass cutting fluid or cutting agent in the production of ultra-thick glass, which has a better edge bending effect.

4.3 Auxiliary edge bending measures

From the horizontal view of the glass ribbon, the edge temperature of the ultra-thick glass is low, the middle temperature is high, the tensile stress in the middle is large, and the compressive stress at the edge is large; in the thickness direction, because the ultra-thick glass core cools slowly and the upper and lower surfaces cool quickly, the tensile stress in the glass core is large and the compressive stress on the upper surface is large. This makes it difficult to control the edge bending quality of ultra-thick glass after cutting. This stress distribution condition is inevitable in the production of ultra-thick glass, but the severity is different. To improve the edge bending quality, auxiliary measures are mainly taken in the cutting area to change the pressure near the cutting line of the glass ribbon.

First, a water cooling device can be set inside the cutting line for cooling and cooling, increasing the tensile stress at the cutting line to facilitate the edge bending process.

Secondly, two-edge bending is adopted. That is, two cuts are made on the edge, and two longitudinal cutting lines are left on the edge of one side of the glass strip at the same time. The outermost part of the glass edge is first removed from the first cutting line close to the edge, which will release part of the compressive stress; the edge is removed again at the second cutting line, which will have better-cutting quality. This method is more effective for the difficulty of cutting and edge bending caused by too high stress, but it is ineffective for the case of too low stress.

5. The edge bending method and selection of ultra-thick glass

According to the pulling volume scale of the float production line and the annealing quality control, there are many options for edge bending.

5.1 Automatic pressure wheel roller pressure edge bending

In the case of a good annealing effect, the tensile stress value in the center of the glass is very low and the compressive stress on the surface is also low. When the cutting wheel passes through the glass, the compressive stress on the surface of the glass will be released, and the glass can be broken along the cutting line with a little external force. At this time, a relatively gentle rolling method can be used, such as using a rolling device to lift the glass strip by 1~2mm at a position about 50mm inside the glass cut and using a pressure wheel to roll at a position about 120mm outside the cut (side of the edge drawing machine tooth mark). The glass edge is gradually peeled off as the glass plate moves forward, which has a good effect on improving the quality of the glass edge section.

5.2 Automatic stamping and edge pressing

Currently, there are two methods used: single-point stamping and multi-point pressure relief. Single-point stamping edge bending is too concentrated, which easily expands the impact of small defects at the stamping point on the quality of the glass edge, so it is very easy to produce concave edges or bevels at the stamping position; multi-point pressure relief edge pressing method can reduce such defects because the glass force points are relatively dispersed and uniform.

5.3 Manual edge bending

Since most ultra-thick glass products are large (mainly long), and the length of some products even exceeds the limit length of the edge bending mechanism in the cutting area (especially some old production lines that have been in operation for more than 10 years), manual edge bending is the norm in the edge bending process of ultra-thick and ultra-long glass. The manual edge bending device generally uses a conical plastic hammer or an iron hammer to expand the cut mark by knocking and vibrating below the glass cutting production line, and the glass edge cracks along the cutting line. To minimize the impact of the knocking action on the edge quality, the manual knocking method needs to be adjusted according to the actual annealing situation.

First, try to use secondary edge bending to release stress through primary edge bending and reduce the impact of secondary edge bending on edge quality.

Secondly, if the annealing is good (i.e. the edge is easy to crack along the knife mark after knocking), you can tap the starting position at the lower part of the cutting line to produce cracks, and then tap the edge of the glass on the upper surface of the edge drawing machine or the outer edge of the indentation to make the glass edge crack along the knife mark and extend backward. This is equivalent to the action of gradually "breaking apart", reducing the vibration impact caused by knocking on the lower surface, thereby reducing cross-sectional defects.

Third, for glass plates with poor annealing quality, because the knocking method on the upper edge cannot make the cracks completely along the cutting line, at this time, only the knocking vibration on the lower surface of the glass plate can be used, and handled in a "high frequency and small amplitude" manner. Since poorly annealed glass plates are prone to missing corners or large bevels, the initial knocking action is best about 300mm away from the front end of the glass plate, and then knock forward after the crack appears, which can reduce the chance of missing corners. The premise of using this method is to accurately judge whether the problem lies in the cutting wheel, cutting pressure, or poor annealing, otherwise, improper measures will be counterproductive.

6. The conclusion

6.1 The influence of internal stress on the cutting and edge breaking of ultra-thick and ultra-long float glass cannot be ignored. Reasonable analysis and control of internal stress can not only reduce cracks and damage during the cutting process but also improve cutting quality and efficiency.

6.2 Selecting a suitable cutting wheel and pressure and taking reasonable auxiliary measures are necessary conditions to ensure cutting quality. The angle of the cutting wheel should match the thickness of the glass. Reasonable pressure and auxiliary measures can reduce the occurrence of cutting and edge-breaking defects.

6.3 The glass edge breaking method is an important step to ensure the quality of the section of ultra-thick and ultra-long glass after cutting. Using appropriate edge breaking methods (including different manual edge knocking methods based on annealing conditions) can improve the edge quality of ultra-thick and ultra-long glass to a certain extent.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.