Impact of warm edge application on user experience and structural safety in glass curtain wall construction.

1. The definition of warm edge insulating glass

Warm edge insulating glass is relative to traditional aluminum and stainless steel spacer insulating glass. It is clearly defined as a thermally improved spacer in the international industry standard "Insulating Glass". The standard stipulates that the thermal conductivity factor is less than 0.007W/K. Generally speaking, spacers made of non-metallic materials or non-metallic and thin metal composites can basically meet the requirements of the standard, so they can be called warm edge insulating glass spacers.

2. The application of warm edge insulating glass

Many practices have proved that insulating glass can improve energy saving by 30%. As an environmentally friendly product, it is widely used. However, the actual energy saving target of 75% has not been achieved, mainly in the window frame position. In the test, this part often fails. Because the materials that can guarantee the corresponding structural performance on the market are all relatively high in thermal conductivity. Therefore, condensation, dew, and frost are prone to occur on the edge of the insulating glass. To improve such problems, the research direction focuses on the thermal properties of the spacer material. Therefore, warm-edge technology emerged. Its core is to use materials with lower thermal conductivity to replace traditional aluminum spacers, reduce heat conduction in this part, and play a higher energy-saving role.

3. More experiences brought to users by warm edge insulating glass

1) Warm edge spacers have low thermal conductivity and excellent thermal insulation properties, which prevent a large amount of heat from being lost through linear heat transfer at the edge. Due to its good thermal insulation properties, the surface temperature of the glass edge area on the indoor side in cold winter can be kept closer to the indoor ambient temperature and higher than the dew point temperature, avoiding condensation and frost on the surface, keeping the glass surface dry, and avoiding problems such as profile mildew, bacterial growth, damage, shortened life, and increased maintenance costs due to humidity. The indoor surface temperature is increased by more than 5°C, which effectively increases the comfortable use function. Even if you are close to the window, you will not feel the heat in the front and the cold in the back, and it can also effectively save energy.

2) The use of warm edge spacers can increase the temperature of the glass edge, thereby reducing the overall temperature difference of the glass, improving the temperature gradient distribution of the glass surface, reducing temperature stress, and thus reducing the risk of breakage.

3) When selecting the spacer, comprehensively consider the color and profile matching, surface glare, and other influencing factors to obtain a better appearance effect. Some non-metallic warm edge materials are matte materials with slow surface reflection and no glare. At the same time, it has a variety of color options to meet the matching of window frame profiles of different types, colors, and styles, and achieve a perfect overall window appearance effect, so that the warm edge can also become the finishing touch and decorative highlight of doors and windows, reflecting perfect quality.

4. More comparison of energy-saving calculations of insulating glass

To ensure the reliability of the calculation structure comparison, the meteorological parameters of the project location are given as the relevant parameters and calculation boundary conditions of the local standards around 35° north latitude in the northern hemisphere.

4.1 The insulating glass in the project does not adopt a warm edge design

4.1.1 Thermal calculation of glass curtain wall

Thermal analysis of glass model. After finite element analysis, the overall heat flow of the thermal node model is 7.962W/m, so the overall U value of the node is 0.995W/(m2·K).

4.1.2 Column thermal finite element analysis calculation

Calculate the most unfavorable position. After finite element analysis, the overall heat flux of the thermal node model is: 38.084W/m, the heat flux through the panel is 17.227W/m, the outdoor length of the node model is: 0.583m, the projection length of the node model plate is 0.401m, and the projection length of the node model frame is 0.098m. According to the "Regulations for Thermal Calculation of Building Doors, Windows and Glass Curtain Walls", ψ=0.132W/(m·K).

4.1.3 Beam thermal finite element analysis calculation

1) Thermal analysis U value calculation. After finite element analysis, the overall heat flux of the thermal node model is 12.438W/m, so the overall U value of the node model is 1.14W/(m2·K).

2) Calculation of the linear heat transfer coefficient of the joint between the frame and the glass system (or other mosaic panels). Finite element analysis shows that the overall heat flux of the thermal node model is 29.466W/m, and the heat flux through the panel is 19.511W/m. According to the "Thermal Calculation Code for Building Doors, Windows and Glass Curtain Walls", ψ=0.164W/(m·K).

4.1.4 Calculation of the overall U value of curtain wall/doors and windows

The heat transfer coefficient of a single curtain wall should be calculated according to the following formula: the U value is 1.694W/(m2·K).

4.2 The insulating glass in the project adopts a warm-edge design

4.2.1 Curtain wall thermal calculation

1) Calculation of glass curtain walls in various directions.

The parameters listed in Table 1 are substituted into Acw for calculation, not the specific area.

(1) The heat transfer coefficient is UCwD=1.560W/(m2*K).

(2) The shading coefficient is SCCwD=0.253W/(m2*K).

(3) The visible light transmittance is: TcwD=0.338W/(m2*K).

(4) The heat transfer coefficient of the transparent part is UAv=1.560W/(m2*K).

(5) The heat transfer coefficient of the transparent part is UAv=0W/(m2*K).

Table 1 More values of various parameters

| Parameters | n | Ucw | SCCW | rCW | nAr | UcwAcw | SCcwAcw | rcwAcw | Ag | Ap | Ug | Up |

| Values | 0.73 | 1.511 | 0.256 | 0.361 | 6.845 | 1.103 | 0.187 | 0.264 | 0.73 | 0.000 | 1.511 | 0.000 |

2) Calculation of thermal performance of the grid scheme.

(1) Calculation of optical thermal performance of transparent panel (glass) is shown in Table 2.

Table 2 Calculation of optical and thermal properties of transparent panel (glass)

| No. | Name | A | g | U | SC | r | Inclination |

| 1 | 8 + 1.52PVB +Double Silver 8 Low-E + 12AR+ 12 (warm edge) | 1.006 | 0.252 | 1.277 | 0.289 | 0.418 | 90 |

(2) Results.

Heat transfer coefficient:

4.2.2 Summary of Curtain Wall Thermal Performance

1) Panel calculation results are shown in Table 3.

Table 3 The panel calculation results

| Name | U | SC | τ | Inclination |

| 8 + 1.52PVB +Double Silver 8 Low-E + 12AR+ 12 (warm edge) | 0.277 | 0.289 | 0.418 | 90 |

2)Thermal calculation results of curtain walls in various directions are shown in Table 4.

Table 4 Summary of thermal calculation results of curtain walls in various directions

| Name | A | U | SC | τ | Ag | Ug | Ap | Up |

| East, South, North, and South orientation | 1 | 1.560 | 0.253 | 0.3338 | 1 | 1.560 | 0.000 | 0.000 |

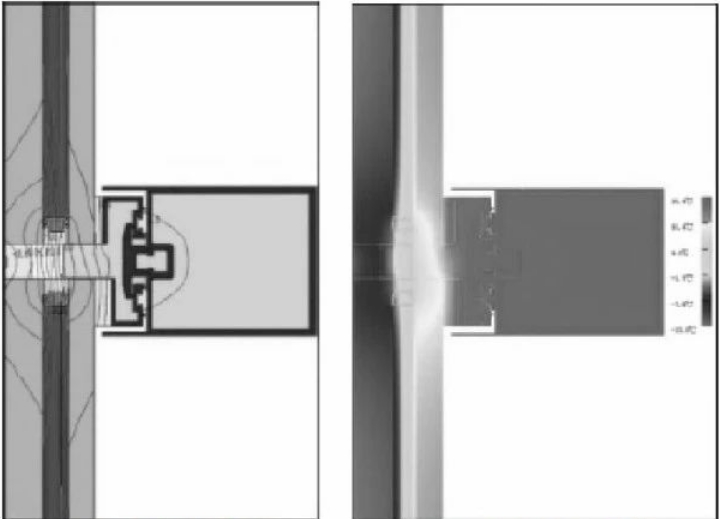

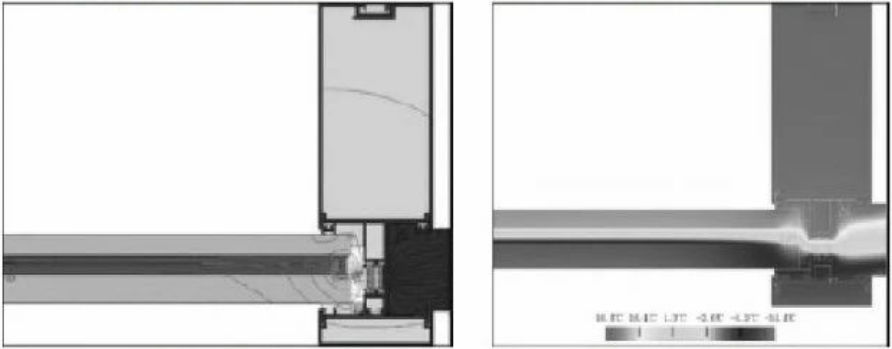

4.2.3 Frame two-dimensional heat transfer calculation diagram

Calculation parameters are shown in Table 5, and calculation results are shown in Figure 1.

Table 5 The calculation parameters

| Heat transfer coefficient UW/(m2*K) | Total sunlight transmittance/g | Direction of gravity | Frame projection length/mm | Linear heat transfer coefficient w/(m*K) |

| 0.924 | 0.025 | downward | 70.000 | 0.090 |

(a)Beam temperature line diagram (b)Beam temperature field diagram

(c)Column temperature line diagram (d)Column temperature field diagram

Figure 1 The aluminum frame 2D heat transfer calculation diagram

5. The comparison of insulating glass structure calculation

5.1 The insulating glass in the project did not use warm edge structure calculation

5.1.1 Glass calculation

1) Glass area. B: 1.85m, H: 3m, A: 5.55m2.

2) Glass panel deadweight. GSAk: Average deadweight (excluding aluminum frame): G=5.541kN.

3) Glass strength calculation. The selected panel material is 10(TP)+12+10(TP)+12+10(TP) double insulating glass.

Combination of wind load and earthquake load: q=2.101kN/m2.

h, n, r3: Load distribution coefficient of outer, middle, and inner glass, r1=0.366, r2=0.333, r3=0.333.

The surface loads on each layer of glass under the combined action of surface load design value are: q1=0.770kN/m2, q2=0.700kN/m2, q3=0.700kN/m2.

The loads on each layer of glass under the standard value of surface load are: qk1=461kN/m2, qK2=0.419kN/m2, qk3=0.419kN/m2.

Parameter 9 calculation: According to the "Glass Curtain Wall Engineering Technical Specifications", after checking the table, η1=0.979, η2=0.985, η3=0.985.

Stress calculation of each layer of glass: According to the "Glass Curtain Wall Engineering Technical Specifications", it is obtained: σw1=13.129N/mm2, σw2= 12.001 N/mm2, σw3=12.001N/mm2. Through calculation, it is found that the glass stress is less than fg=84N/mm2, and the strength is full.

4) Calculation of glass mid-span deflection. According to the specification "Glass Curtain Wall Engineering Technical Specifications," The result is df=7.678mm≤dflim=833mm, the deflection meets the requirements.

5.1.2 Calculation of crossbeam

To ensure the safety of glass installation, the specification of the glass crossbeam is 75x75x2.5(H).

1) Calculation of crossbeam strength.

(1) Bending moment of crossbeam under deadweight (kN-m).

Hh: 3m, Bh: 1.85m, GAkhu: 0.8kN/m2, GAkhd: 0.4kN/m2.

Standard value of crossbeam deadweight load (kN/m): Ghk=2.4kN/m,

Design value of crossbeam deadweight load (kN/m): Gh=3.12kN/m,

The gravity load borne by the end of the crossbeam is Gh=2.886kN,

Bending moment under deadweight load (kN m): Mhg=1.334kNm.

(2) Calculation of combined loads on the beam.

Load combination: qAk=1.177kN/m2, qAU=l.990kN/m2, qAd=l.878kN/m2.

(3) Bending moment of the beam under combined load (kNm): Mh=0.721kNm.

(4) Beam strength: Calculated strength of the beam (N/mm2):

σ=79.227N/mm2<fa=140N/mm2,

σd=145.207N/mm2<fad=215N/mm2,

the positive stress strength of the beam meets the requirements.

3) Calculation of beam stiffness.

(1) Verification of deflection of the main section of the beam. U=3.041mm<20mm, Du=0.001<1/180, Dg=0.001<1/500, so the deflection of the main section of the beam meets the requirements.

(2) Deflection verification of the composite section of the beam. The comprehensive bending is U=3.041mm<20mm; Du=0.001<1/250; Dg=0.001 <1/500, the deflection of the composite section of the beam meets the requirements.

4) Calculation of the shear strength of the beam.

(1) Q: Design value of the shear force of the beam under combined load (kN).

The combined load line distribution of the upper part of the beam is triangular distribution Qu=0.851kN; the combined load line distribution of the lower part of the beam is trapezoidal Qd=0.375kN.

(2) Shear force on the beam: Q=1.227kN.

(3) According to the "Technical Specifications for Glass Curtain Wall Engineering" , the shear stress of the beam profile is calculated to be τ=9.737N/mm2≤81.2N/mm2; the superimposed section profile τd=8.451N/mm2≤125N/mm2, and the shear strength of the beam meets the requirements.

5.2 Calculation of the warm edge structure of insulating glass in the project

5.2.1 Glass calculation

1) Glass area. B: 1.85m, H: 3m, A: 5.55m2.

2) Glass panel deadweight: average deadweight (excluding aluminum frame): G=5.171kN.

3) Glass strength calculation.

Selected panel material defect: 8(TP)+1.52+8(TP)G2+12(TP) laminated insulating glass; q=2.087kN/m2.

The current glass structure is 8(TP)+1.52+8(TP)+12+12(TP) laminated insulating glass: r1=0.204, r2=0.204, r3=0.627.

The surface loads on each layer of glass under the combined effect of the surface load design value are: q1=0.427kN/m2, q2=0.427kN/m2, q3=1.310kN/m2.

The loads on each layer of glass under the surface load standard value are: qki=0.257kN/m2, qk2=0.257kN/m2, qk3=0.789kN/m2. Parameter 8 calculation, under the surface load standard value, according to the formula 6.123 of "Glass Curtain Wall Engineering Technical Specifications" (JGJ102-2003), we get: t)2=0.959, q3=0.990.

Stress calculation of each layer of glass: According to the formula of Article 6.1.2-1 of the specification "Technical Specifications for Glass Curtain Wall Engineering", we can obtain: σw1=11.129N/mm2, σw2=11.129N/mm2, σw3=15.672N/mm2.

Through calculation, it is found that the stress of glass is less than fg=84N/mm2, and the strength of glass meets the requirements.

4) Calculation of glass mid-span deflection. According to the calculation in the "Technical Specifications for Glass Curtain Wall Engineering", dr=8.322mm<dflim=30.833mm is obtained, and the deflection meets the requirements.

5.2.2 Calculation of crossbeam

To ensure the safety of glass installation, the specification model of the glass crossbeam is proposed to be 65x90x3(H).

1) Calculation of the strength of the crossbeam.

(1) Bending moment of beam under dead weight (kNm): G: 0.7m, Bh: 1.85m, GAkhu: 0.5kN/m2, GAkhd: 0.5kN/m2.

The standard value of the deadweight load of the beam (kN/m): Ghk=0.35kN/m,

The design value of the deadweight load of the beam (kN/m): Gh=0.455kN/m,

Gravity load is borne by the end of beam: Grh=0.420kN,

Bending moment of beam under deadweight load (kN*m) Mhg=0.194kN*m.

(2) Calculation of combined load borne by the beam.

The standard value of the combined load on the beam surface: qAk=1.173kN/m2,

The combined design value of the combined load on the beam surface: qAu=1.900kN/m2, qAd=1.900kN/m2

(3) Bending moment of the beam under combined load (kN m): Mh=0.772kNm.

(4) Beam strength: Calculated strength of the beam (N/mm2): σ=52.696N/mm2≤fa=140N/mm2, positive stress strength meets the requirements.

The combined bending is: U=Uhu+Uhd=2.519mm<20mm, Du=0.001<1/180, Dg=0.0006<1/500, deflection meets the requirements.

The combined load line distribution of the upper part of the beam is trapezoidal distribution Qu=0.498kN, and the combined load line distribution of the lower part of the beam is triangular distribution Qd=0.813kN.

The shear force on the beam is Q=1.311kN.

According to the specification "Technical Specifications for Glass Curtain Wall Engineering", the shear stress of the beam profile τ=6.625N/mm2≤81.2N/mm2 Is calculated, and the shear strength meets the requirements.

6. The conclusion

Through the comparison of insulating glass energy saving and structural calculation, it is not difficult to find that the heat transfer coefficient of insulating glass using a warm edge is relatively low. Since the thermal conductivity of each unit glass is comprehensively evaluated, and the general thermal conductivity calculation is affected by the frame, in other words, the thermal conductivity of the frame is reduced, and the corresponding glass part can reduce the energy-saving effect, and the corresponding glass size can be reduced. The self-weight of the glass is reduced, and the cross-sectional size of the glass beam is reduced. Therefore, the use of warm edge technology reduces energy-saving losses, increases structural stability, reduces engineering costs, and increases the living experience of residents.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.