Causes and measures for fogging in insulating glass of doors and windows.

With the improvement of the level of modern home decoration, people tend to enjoy a quiet and comfortable living environment. Therefore, when choosing doors and windows, they prefer to choose aluminum alloy insulated glass windows. However, what puzzles many glass window and door suppliers is that the insulated glass of doors and windows will fog up. , what's going on?

This fogging phenomenon is caused by the unqualified manufacturing process of insulating glass for aluminum alloy doors and windows. To understand the causes and solutions, we must first understand the manufacturing process of insulating glass.

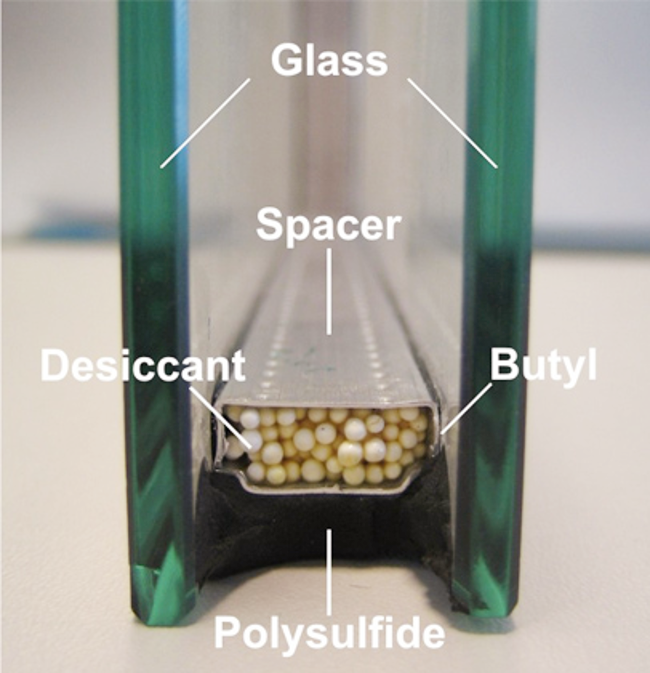

The basic production process of insulating glass consists of glass washing and drying, filling with molecular sieves, application of butyl sealant, plate-sheet combination, and application of the second sealant. Every link is related to the selection of materials, the proficiency of the operators, and the quality of processing.

Figure 1 The fogging phenomenon in insulating glass of doors and windows

The glass washing and drying

The cleanliness of the glass is the primary measure of appearance quality. However, in current production, many manufacturers, especially developing manufacturers, often do not pay enough attention to washing glass, resulting in a large number of substandard products flowing into the market. If the oil stains and sweat on the glass cannot be thoroughly washed, the adhesion of the sealant to the glass will be greatly weakened, thereby reducing the sealing effect of the insulating glass. Therefore, the sealing performance of insulating glass is closely related to whether the glass is clean to a large extent.

The desiccant molecular sieve filling

The purpose of adding desiccant is to maintain a qualified initial fog point of the insulating glass. Therefore, a qualified desiccant must simultaneously meet the three functions that a desiccant should have. If the desiccant has poor adsorption capacity and cannot effectively absorb moisture that enters the air layer through diffusion, it will cause moisture to accumulate in the air layer, increase the moisture pressure, and increase the fog point of the insulating glass, so atomization is very likely to occur.

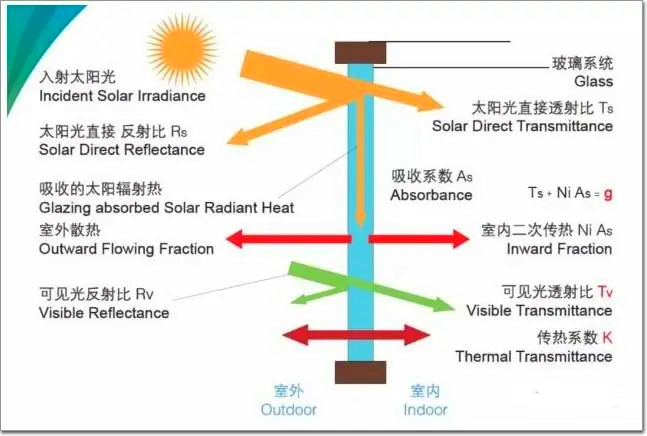

Figure 2 The insulated glass internal structure

The failure of the edge sealing of the insulating glass means that the doors and windows lose their proper functions. Not only does the design energy-saving performance of the doors and windows fail to meet the requirements, but consumers cannot see the outside world clearly through the fogged air layer, which affects the transparency of the insulating glass. It also reduces the thermal insulation effect. Long-term fogging will also cause mildew or alkali accumulation on the inner surface of the glass, resulting in white spots, which seriously affects the appearance quality of the insulating glass.

It can be seen that choosing high-quality insulating glass sealant is the first and key to prevent insulating glass from atomizing. The selected insulating glass sealant should meet the requirements of industry standards, and the first and second sealants of double-layer insulating glass should be suitable and cannot dissolve or react with each other. Otherwise, it may cause contamination of the glass surface and even aging.

Figure 3 The first and second sealants of double-layer insulating glass

The combination-sealing

The combination and second sealant determine the overall quality of the insulating glass. If there is a gap between the two sealants, it will cause air leakage. At the same time, you should pay attention to applying a second sealant that is too thin. After installation and use for some time, the sealant will deteriorate due to changes in ambient temperature, sunlight, and wind pressure. Cracks will form (even if very small cracks exist), and water vapor may slowly enter the glue layer, forming atomization, and losing its sealing property and sealing effect.

The finished double-layer insulating glass needs a storage period of about 3 days so that the double-layer insulating glass sealant has sufficient time to chemically bond and achieve the best sealing state. If the parking period is too short, the sealant will not have enough time to bond. After transportation, vibration, sunlight, and especially rain, the sealing effect of the sealant will be greatly reduced. In severe cases, fog will appear in a short period.

Figure 4 The combination and second sealant sealing

The assembly of insulated glass producing

When assembling insulating glass, if the insulating glass sealant comes into contact with other sealing materials (especially curtain wall weather-resistant sealant), and these sealing materials contain plasticizing components that can dissolve butyl sealant, these plasticizing components will pass through the insulating glass. The second seal of the glass migrates to the surface of the first sealant, thereby dissolving the first sealant and causing phenomena such as thinning and flowing. Therefore, when assembling insulating glass, it is necessary to conduct corresponding compatibility tests and select matching sealing materials that are compatible with the insulating glass sealant. It is best to use sealing materials from the same manufacturer to reduce the occurrence of such phenomena.

Reducing and eliminating the fogging phenomenon of insulated glass of aluminum alloy doors and windows depends on every aspect of the production of aluminum doors and windows. The entire production process needs to be closely monitored to eliminate substandard products.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.