Analysis of typical failure modes of insulating glass in building curtain walls.

1. The preface

The development of high-efficiency and energy-saving glass is one of the important ways to reduce building energy consumption. Insulating glass is a glass product made of two or more pieces of glass, separated by a spacer frame with desiccant in the middle, and sealed around the perimeter. It has good thermal insulation properties and has been widely used in building doors, windows, and curtain walls. In the early 1960s, some developed countries began to develop insulating glass. In the early 1970s, trial production was successful and began to be applied. By the mid-1980s, after the first fully automated insulating glass production line came out, insulating glass manufacturing in various countries around the world entered a new stage. stage. So far, the annual production of insulating glass in the world has exceeded 1 billion square meters, of which China has become the country with the largest production and usage in the world, and has maintained steady growth for a long time. At present, insulating glass is the most widely used in new buildings. Insulating glass is also known as "today's glass" with a sense of the times. At present, the production technology and application technology of insulating glass in various countries around the world are quite mature, and their actual use range is very wide, which has brought significant energy-saving effects to glass buildings in various countries.The edges of insulating glass are made of organic materials (structural glue, polysulfide rubber, etc.), which have shortcomings such as easy aging, relatively poor weather resistance, air tightness, and water tightness. The energy-saving effect of insulating glass is easy to decline or even fail over time, and its durability is difficult to achieve. commensurate with the life of the building. At the same time, in the early days (early and mid-1990s), the insulating glass market was still relatively chaotic. To reduce costs, some manufacturers cut corners, insufficient glue width for insulating glass, and even used inferior structural glue, resulting in poor durability of insulating glass and prone to interfaces. Due to debonding and air leakage, this part of insulating glass is still in service in some buildings so far. In addition, after the insulating glass structural adhesive is used for a certain period, its physical aging will also weaken the strength of the bonding interface, causing interface cracking and air leakage under the action of environmental cyclic loads. Due to the huge usage of insulating glass and the factors of insulating glass itself, the quality and safety issues of insulating glass are relatively prominent. The LIJIANG Glass system summarizes the various failure modes of insulating glass on building curtain walls and analyzes their failure causes in detail. The analysis of this article is expected to guide relevant engineering technicians to design and use curtain wall insulating glass more rationally, reduce the occurrence of safety and quality accidents, and thereby improve the safety, reliability, and durability of insulating glass.

2. The typical failure modes of insulating glass

2.1 Dew point, condensation, and water accumulation of insulating glass

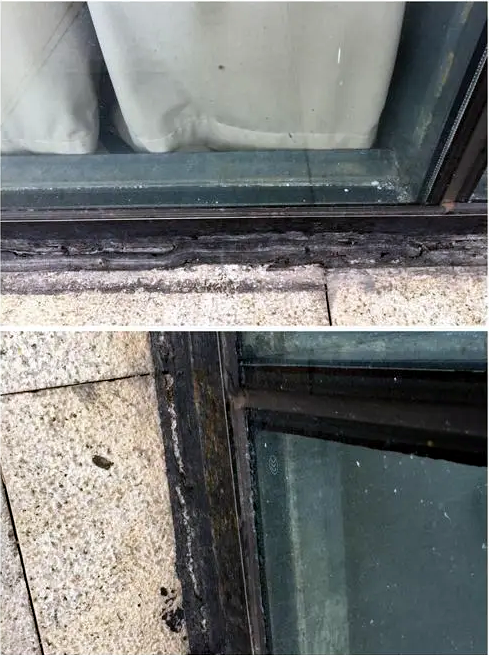

Dew point and condensation in insulating glass are the most common failure modes. In the production process of insulating glass, if a sealant with a large gas permeability coefficient is selected, it will easily lead to poor sealing of the insulating glass, or the sealing components of the insulating glass may be debonded or broken, or the sealant may fail or age. The watertightness of the sealing components is insufficient; for some oversized insulating glass, the sealing components at the edge of the insulating glass are dislocated and deformed due to temperature differences or during installation, resulting in sealing failure. The various factors mentioned above create channels for water vapor to enter the open space of the insulating glass, causing the dew point of the insulating glass, and even water accumulation in the cavity (as shown in Figure 1), which directly causes the insulating glass to fail. When the insulating glass is coated glass, due to the action of water vapor, the rainbow phenomenon will appear in the coated insulating glass cavity or the film layer will be corroded, oxidized, etc.

Figure 1 The dew point, condensation, and water accumulation caused by seal failure of insulating glass

2.2 Insulated glass sealant flows and leaks oil

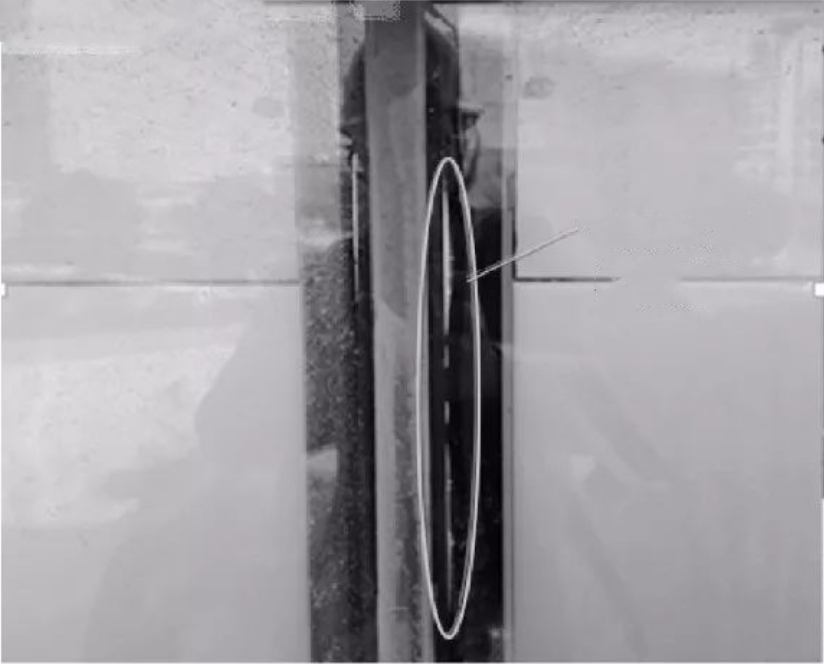

Silicone sealants are produced with hydrogen-terminated polysiloxane as the base material and dimethyl silicone oil as the plasticizer. The product quality is stable. As market competition becomes increasingly fierce, some companies incorporate low-boiling point substances, such as white oil, into silicone sealant products to replace dimethyl silicone oil to reduce costs, greatly reducing the durability of the product. White oil is a colorless, odorless white oily long-chain alkane produced by high-pressure hydrogenation and refining of petroleum lubricating oil. It is often used as a textile lubricant and coolant. When used in trace amounts, it can improve the surface gloss of sealant products. The basic composition of white oil is a saturation structure. It has a small molecular weight, low boiling point, and is easy to volatilize. Especially when the ambient temperature is high, the white oil will volatilize and ooze out, and the silicone glue will gradually harden over time, shrink, or even crack, resulting in bond failure (see Figure 2). The main component of butyl glue, the first sealant used in insulating glass, is polyisobutylene. Its molecular chain is dominated by C-C bonds, which are similar to white oil, and the polarity between the two is similar. According to the principle of similar miscibility, when butyl sealant encounters white oil, it will be swollen and dissolved, causing the insulating glass sealant to flow (see Figure 3). Once the insulating glass sealant flows and leaks oil, the insulating glass seal will also fail.

Figure 2 The three-layer sealant of insulating glass hardens, shrinks, and cracks

(The card can be inserted into the gap formed by the debonding)

Figure 3 The state of oil leakage inside the insulating glass sealant

2.3 The outer piece of insulating glass falls off

There are mainly four factors that cause the outer piece of insulating glass to fall off:

(1) The bonding strength between the insulating glass sealant and the glass does not meet the relevant requirements.

The stability of the insulating glass system is achieved by the insulating glass sealant. At present, the sealing structure of insulating glass used on curtain walls is mainly a double-pass sealing structure, which consists of two sealants. Butyl hot melt adhesive is usually used as the first seal, coupled with structural sealant, such as polysulfide sealant or silicone sealant serves as the second seal. For some glass curtain walls that adopt a hidden frame structure, during the use of the insulating glass, the weight of the outer sheet of the insulating glass is completely borne by the second sealant. Once the second sealant has insufficient bonding performance or causes bonding due to aging, etc. Performance degradation and other phenomena can cause the outer piece to fall off as a whole, causing serious safety hazards. In addition, some insulating glass in developing country uses polysulfide sealant as the secondary sealant. Due to the poor UV resistance of polysulfide sealant, the sharp decline in bonding strength with the glass after aging, and its insufficient strength, when this type of glass is used in When the frame glass curtain wall is hidden, it is very easy to cause the outer piece of insulating glass to fall. "Technical Specifications for Glass Curtain Wall Engineering" and "Silicone Structural Sealant for Insulated Glass" both put forward requirements for the compatibility of the secondary sealant of insulated glass and the materials in contact with it. Before use, silicone structural sealants should be tested for compatibility with glass, metal frames, spacers, positioning blocks, and other sealants. They can only be used after passing the compatibility test. If the silicone structural sealant is incompatible with the materials in contact with it, the bonding strength of the secondary sealant will be reduced or completely lost, and it will not be able to withstand the wind load of the outer glass and the weight of the glass, resulting in the appearance of the insulating glass.

(2) The width of the second sealant injection for the insulating glass does not meet the requirements.

"Insulated Glass" stipulates that the width of double-pass sealing outer sealant injection is 5~7mm, and products with special specifications or special requirements shall be agreed upon by both parties. In the "Technical Specifications for Glass Curtain Wall Engineering", it is stipulated that silicone structural sealants should be subjected to load-bearing limit state calculations based on different stress conditions. The bonding width and bonding thickness should be determined through calculation respectively, and the bonding width of structural adhesives It should not be less than 7 mm, and the bonding thickness should not be less than 6 mm. The "Quality Inspection Standards for Glass Curtain Wall Projects" stipulates that the width of the secondary silicone structural sealant layer of insulating glass should meet the structural calculation requirements. "Technical Specifications for Glass Curtain Wall Engineering" is the basic basis for the design and calculation of glass curtain walls. It stipulates that the width and thickness of the load-bearing silicone structural sealant in hidden frame and semi-hidden frame glass curtain walls should be determined through calculation, and stipulates minimum width and thickness. For insulated glass used on hidden frame or semi-hidden frame glass curtain walls, the second layer of silicone structural sealant bears wind load, earthquake load, and self-weight load. The injection width and thickness should also be calculated based on the load of the insulating glass. The "Insulating Glass Production Regulations" also stipulate that the width and thickness of silicone structural sealant injection should meet the design requirements, the width should not be less than 7 mm, and the thickness should not be less than 6 mm. The requirements for the injection width and thickness of insulating glass are the same and consistent with relevant industry standards. There is air leakage in the insulating glass sealing component (the gas in the insulated layer is connected to the outside atmosphere). When air leakage occurs in the insulating glass sealing components (such as secondary sealant debonding, breakage, etc.), at this time, in addition to the failure of the heat insulation function of the insulating glass, the load-bearing performance of the insulating glass is also changed. Figure 4 is a schematic diagram of the load-bearing between the insulated layer of insulating glass and the outside atmosphere in the case of sealing and air leakage. In the sealed state, when external load (wind load) acts, since the gas in the sealed insulated layer of the insulating glass, has the function of transmitting load, at this time, the inner and outer sheets of the insulating glass bear the load at the same time. However, once the gas in the insulated layer of the insulating glass leaks, the gas in the insulated layer has no role in transmitting load, and all the external load is borne by the piece of glass that directly bears the load. The load-bearing performance of the insulating glass at this time drops by about half. In particular, when the outer sheet of insulating glass is under negative pressure, for hidden frame glass curtain walls, the negative pressure acting on the glass panel will be transferred to the secondary sealant at the edge of the insulating glass and cause it to be subjected to tensile force. Repeating the above situation can easily cause damage to the secondary sealant of the insulating glass, increase the probability of debonding and failure, and cause the outer sheet to fall off.Initial state (unloaded)/sealed state (loaded)/permeability leakage state (loaded)

Figure 4 Schematic diagram of the load-bearing performance of insulating glass under sealing and air leakage conditions

(3) The secondary sealant bears long-lasting and vibration load effects.

When assembling the insulating glass used in hidden-frame curtain walls, if there is no supporting block under the hidden-frame glass, the second sealant will always bear the long-term self-weight load of the glass, causing it to creep and fatigue failure. In particular, some curtain wall opening fans use insulating glass assembled with hidden frames. Since the opening fans are subject to constant artificial opening and closing, the second sealant bears the dynamic load of the glass gravity, which is prone to dynamic fatigue damage and accumulation, accelerating the process. The debonding failure of the second sealant caused the entire outer piece of the opening fan's insulating glass to fall off.

2.4 Environmental temperature difference and pressure difference cause breakage and deformation of insulating glass

There is often a certain difference between the ambient temperature and air pressure corresponding to the insulated glass during production and service, which will cause the gas sealed in the hollow layer to expand or contract. When the insulated glass is in service, the ambient temperature is higher than the temperature during empty production, or If the atmospheric pressure is lower than the atmospheric pressure during production, the insulating glass will expand outward, otherwise, it will be concave. When the recess is severe, the inner and outer pieces of the insulating glass may stick to each other, as shown in Figure 5.

Figure 5 The temperature difference causes the inner and outer sheets of insulating glass to come into contact

When the ambient temperature or pressure difference changes large enough, it will have a very adverse impact on the insulating glass, and even directly cause the insulating glass to break and fail. LIJIANG Glass was once exposed to a curtain wall project in which the insulated glass cracked due to differences in air pressure. After the insulated glass was produced and transported to the glass curtain wall construction site, the phenomenon of expansion occurred. Among them, the insulated glass made of untempered glass was damaged during transportation. A large number of cracks occurred and continued to crack after being installed on the curtain wall. The probability of damage reached more than 30%, and even some tempered insulating glass also cracked. Therefore, the problem of insulating glass rupture caused by severe environmental pressure differences requires sufficient attention, and sometimes corresponding measures must be taken, such as using a pressure balancing device inside the insulating glass.

2.5 Temperature changes cause deformation and failure of insulating glass sealing components

During the service of insulated glass, due to the cyclic effects of indoor and outdoor temperature differences, changes in ambient temperature, and other factors, the sealing unit of the insulated glass product will undergo certain expansion and dislocation deformation.

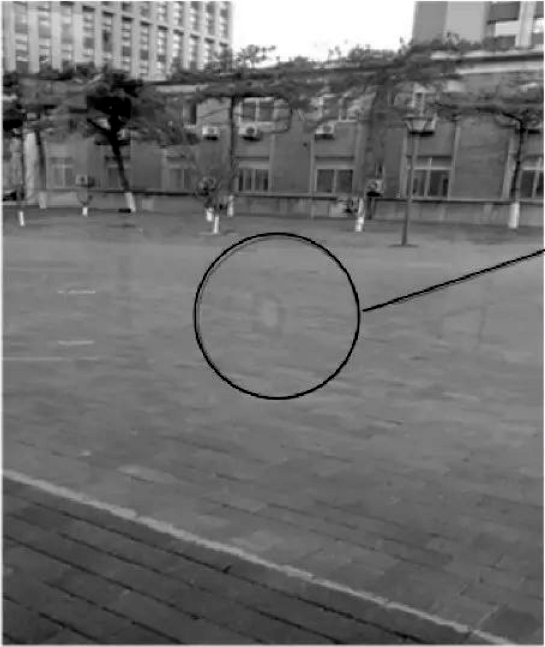

Once the edge sealing component deforms too much, it will cause the first sealant to be extruded, resulting in insufficient width and thickness of the sealant, or even degumming and breakage, accelerating the airtight failure of the insulating glass, causing dew point and condensation of the insulating glass, and affecting the service life of the insulating glass. During the inspection of the existing glass curtain wall, the author found that it is very common for the first sealant (butyl extruder) of the insulating glass to be squeezed out, causing the glue to break and the aluminum frame strips to be exposed (see Figure 6). This phenomenon The situation is not caused by the quality of the medium glass itself, but by changes in ambient temperature.

Figure 6 The phenomenon of butyl extruder being squeezed out of insulating glass

In addition, as the application of insulated glass continues to become larger and larger, manufacturers and designers are also very concerned about the reliability of edge-sealing components. Because the size of insulated glass increases, the ambient temperature will cause greater edge dislocation and deformation, thus causing greater edge dislocation and deformation. It is more likely to cause the insulating glass sealing component to fail. As LIJIANG Glass mentioned, the use of Automatic jumbo-size insulating glass sealing lines can effectively solve the above problems.

2.6 Tempered glass explodes

The self-explosion of tempered glass is common during the service of insulating glass. Especially when the outer piece self-explodes, the tempered glass fragments fall from high altitudes, which can easily cause safety accidents. The fundamental factor causing the self-explosion of tempered glass is the impurities inside the glass (mainly NiS impurities). Since the self-explosion of tempered glass is difficult to predict and control, it is considered a "cancer of glass". After the self-explosion of tempered glass, the obvious white explosion source can be seen in the damage morphology, and it is in the shape of a "butterfly spot", as shown in Figure 7.

Figure 7 Self-explosion rupture morphology of tempered glass caused by heterogeneous particles

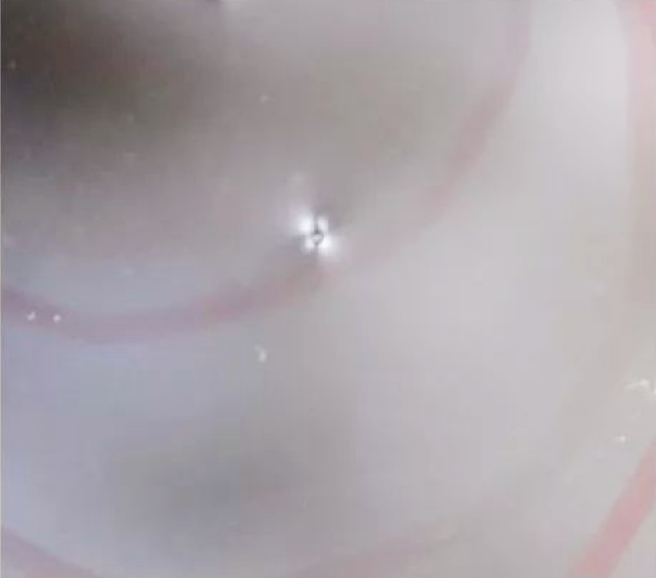

Near the "butterfly spot", through a magnifying glass, a heterogeneous particle can often be seen, see As shown in Figure 8.

Figure 8 Magnified view of heterogeneous particles from the self-explosion source of tempered glass

Domestic self-destruction rates vary among manufacturers, ranging from 3% to 0.3%. Generally, the self-explosion rate is calculated based on the number of pieces, without considering the area size and thickness of the single piece of glass, so it is not accurate enough and cannot be compared with each other more scientifically. To uniformly calculate the self-destruction rate, unified assumptions must be determined. Unified conditions are stipulated: every 5 to 8 tons of glass contains one nickel sulfide sufficient to cause self-explosion; the average area of each piece of tempered glass is 1.8 square meters; the nickel sulfide is evenly distributed. Then it is calculated that the self-explosion rate of 6mm thick tempered glass is about 3‰~5‰. This is consistent with the actual value of high-level glass processing enterprises in some developing countries.

The degree of stress concentration is affected by many factors, and the defects or impurities that cause this stress concentration are also diverse. Detecting or predicting every defect or impurity is much more difficult and cumbersome than detecting stress concentrations. Therefore, we only need to find ways to detect stress concentration points to find the source of self-explosion risk. For transparent materials such as glass, stress concentrations with large stress gradient changes can easily be determined using the photoelastic method. As long as there is stress concentration inside the tempered glass, it can be detected by the photoelastic meter. A large amount of testing experience has shown that by irradiating the glass with a photoelastic instrument and viewing it with the naked eye, stress spots caused by heterogeneous particles above 0.1mm inside the tempered glass can be found. Using ordinary industrial cameras for inspection, the stress spots caused by heterogeneous particles above 0.3mm inside the tempered glass can be identified. The morphology of the heterogeneous particles inside the tempered glass and the stress spots nearby are shown in Figure 9. Therefore, the photoelastic method is used to detect the self-explosion source of tempered glass and evaluate its self-explosion risk, which has good accuracy and operability.

(a) Heterogeneous particles inside tempered glass

(b) Stress spot near heterogeneous particles

Figure 9 Tempered glass self-explosion source and its stress photoelastic spots

3. Summary

The safe and reliable service of insulating glass is directly related to the performance of building curtain walls. During the service process of insulating glass, it is subject to the effects of temperature, wind load, vibration load, rain, and direct sunlight, etc., which will cause it to produce various failure modes.

LIJIANG Glass Comprehensive analyzes the typical failure modes and causes of insulating glass sealing failure, outer sheet falling off, and tempered glass self-explosion, to provide relevant engineering and technical personnel with a more reasonable design and use of curtain wall insulating glass, reduce the occurrence of safety and quality accidents, and improve the use of curtain wall insulating glass. Life span provides a certain reference basis.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.