The development direction of complete sets of insulating glass processing equipment: for beginner guide

As an energy-saving material, insulating glass has a wide range of uses, and it belongs to a class of glass deep-processing products. With the rapid popularization of some special products, which are only favored by high-end buildings in recent years, towards ordinary buildings, air-conditioned passenger trains, display cabinets, refrigerators, and other fields, coupled with people's increasing awareness of environmental protection, energy conservation, and energy conservation policies, And the mandatory implementation of environmental protection standards in some developed countries, the insulating glass market is developing rapidly, and the quality requirements are getting higher and higher. This article briefly introduces the composition and technological process of insulating glass and discusses the research and development direction of the complete set of processing equipment for insulating glass based on understanding the complete sets of equipment required for the processing of insulating glass.

1. Composition and basic manufacturing process of insulating glass

1.1 Composition of insulating glass

The composition of any kind of insulating glass includes the following 3 parts:

(1) The original glass that constitutes the insulating glass.

These original glass sheets can be ordinary float glass, laminated glass, solar control glass, Low-E glass, colored glaze glass, fireproof glass, etc. The original glass used is different, and its function and use location are also different, and according to different needs, 2-layer, 3-layer, or even multi-layer original glass and composite insulating glass can be used;

(2) Space spacer layer and gas.

This is a key factor in ensuring the performance of insulating glass. Aluminum/steel partitions are commonly used with pins and bends, and there are three kinds of gases commonly used in the spacer layer, namely argon, air, and vacuum. To ensure the drying of the gas and prevent the generation of dew point, the spacer is filled with a molecular sieve with strong hygroscopic ability. The needs of glass buyers are different, and the thickness of the insulating glass spacer layer and the choice of the gas inside are also different;

(3) Edge sealing system.

At present, there are two types of insulating glass edge sealing systems recognized in the international market: the traditional cold edge sealing system (trough aluminum type) and the warm edge sealing system (composite rubber strip type, which is improved based on the traditional method. , greatly improve the thermal insulation and sound insulation performance of insulating glass, including single-component insulating glass hot melt adhesive, two-component silicone insulating glass sealant, two-component polysulfide insulating glass sealant, butyl sealant, etc., and Double sealing can prolong the service life of the insulating glass.

1.2 The basic manufacturing process of insulating glass

The thickness of the original glass is generally 3~12 mm, and it is cut by a manual or automatic cutting machine, it is necessary to ensure that the size meets the requirements. Workers should avoid scratches on the glass surface during the operation, and select the original sheet without obvious defects such as air bubbles, slag inclusions, uneven endoplasmic quality, color difference, and delamination. The whole manufacturing process of insulating glass is as follows: cleaning one sheet, one pressing, one gluing; cutting the spacer to a curved frame or pin, pouring molecular sieve, and playing with butyl glue.

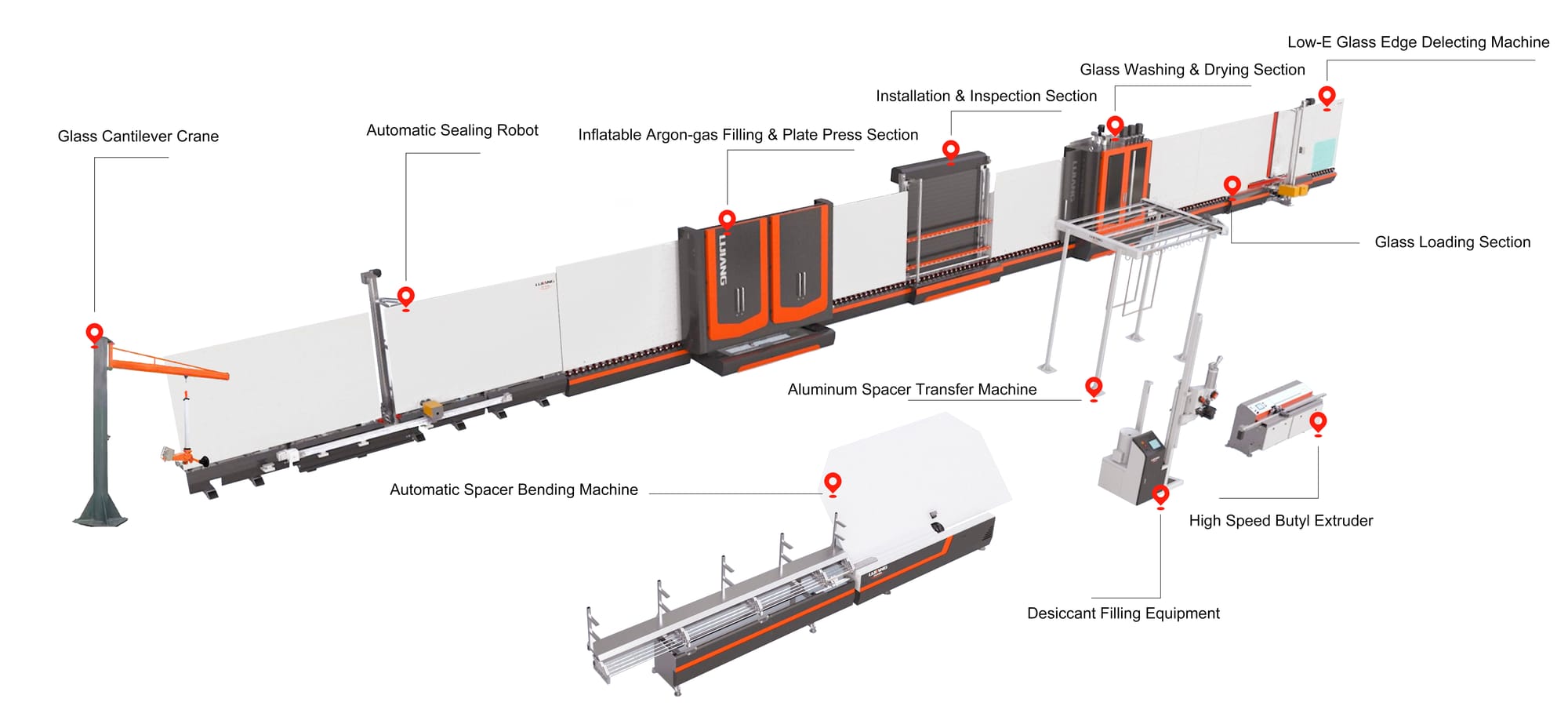

Figure 1 The LIJIANG aluminum spacer strip transfer equipment

(1) Glass washing and drying.

This process must be washed by machine, and manual washing cannot guarantee the washing quality. 5MΩ deionized water is used to ensure the bondability of sealant and glass, and it can also be recycled by filtering the water. Check whether there are residual water droplets or water stains on the glass surface by light. If there is, you can adjust the running speed of the machine, the gap between the brushes, the air volume, and the heating temperature before checking. The assembly of insulating glass should be completed within 1 h after cleaning.

(2) Assembly of rubber strip type insulating glass and aluminum strip type insulating glass.

First, the adhesive tape is pasted and cut. Assembling the strip-type insulating glass requires the processing temperature of the lamination room to be 10~20°C in winter and 20~30°C in summer. When filling the molecular sieve, because the desiccant of the strip type insulating glass is powder, it should be mixed with glue. The effect is slow after homogenization, so relatively low humidity should be ensured in the assembly area of the strip. The processing temperature required to assemble the aluminum strip type insulating glass is in the range of 10~30 °C, and the relative humidity is normal, but a qualified desiccant should be selected and used up within 24 hours after opening. To strengthen the seal, double glue is often used for sealing, butyl glue is the first seal, and polysulfide glue is the second seal.

(3) Glass pressing.

When pressing the rubber strip type insulating glass, pay attention to the alignment of the edges of the laminated glass, and reserve a small opening at the back when pressing, so that the dried gas can overflow from the small opening, or it can be filled with inert gas and then sealed immediately.

(4) Manual or automatic sealant.

For aluminum strip type insulating glass, there should be a distance of 5~10 mm from the outer edge of the aluminum frame to the edge of the glass after lamination, which is used to apply the second sealant. The polysulfide glue should be evenly coated along one side to prevent the inclusion of air bubbles in the middle, and scrape off the residue on the glass surface after coating. So far, the processing of aluminum strip-type insulating glass is completed.

(5) Placement of insulating glass

Whether the insulating glass is placed correctly or not will also have an impact on the final quality of the insulating glass. Whether it is in production, transportation, or storage at the construction site, the design of the stacking rack should take into account the characteristics of the insulating glass, and the stacking rack should be inclined to a certain extent. However, the bottom plane and the side should always maintain an angle of 90°, to ensure that the bottom edges of the two pieces of insulating glass can be placed vertically on the stacking rack. In addition, ensure that the bottom of the glass is not stained with lime oil stains or the like, so as not to erode the second sealant and affect the sealing performance of the insulating glass.With the continuous promotion and application of insulating glass, the requirements of glass buyers and end users are getting higher and higher. Therefore, we should continuously improve the processing technology of insulating glass, vigorously improve the technical level and product quality, and strive to promote the development of insulating glass in the direction of automation and intelligence of glass deep processing.

2. Complete sets of processing equipment for insulating glass

As mentioned above, the main raw materials for the production of insulating glass mainly include glass, aluminum spacers, corner bolts, butyl rubber, polysulfide rubber, desiccant, etc. The main complete sets of processing equipment required for the production of the corresponding insulating glass involve: the aluminum trough insulating glass equipment is equipped with a butyl glue coating, simple auxiliary equipment, washing and drying machines, etc.; large-scale processing plants should be equipped with a glass chamfering machine, washing and drying machine, butyl extruder coating machine, two-component sealant spreading equipment, auxiliary equipment, automatic insulating glass production line. The composite rubber strip type insulating glass equipment is equipped with a rubber strip assembly table, heated roller press, portable installer, glass washing and drying machine, rubber strip assembly table, glass splicing table, heated roller press, portable installer, etc.; large-scale configuration There are glass chamfering machine, cleaning and drying machine, glue strip assembly table, glass lamination table, heating roller press, glass conveying table, portable installer. Combined with the main testing indicators of insulating glass, the research and development direction of the complete set of processing equipment for insulating glass is discussed.

2.1 Main testing indicators of insulating glass

(1) Initial dew point: test whether the air in the insulating glass is dry.

The international industry standard stipulates that the dew point is ≤-40℃.

(2) Ultraviolet irradiation

Test whether the insulating glass sealant contains organic volatiles that affects sight. After the insulating glass sample is continuously irradiated by a 300W UV lamp for 168 hours and stored at a temperature of 23±2℃ for one week, the inner surface of the insulating glass should not appear foggy, oily, or other contaminants.

(3) Sealing inspection

The test the softness and hardness of insulating glass sealant and whether there is leakage. The sample is kept under the condition of 10±0.5 kPa lower than ambient air pressure for 2.5 h, and the thickness growth deviation should be less than 15%.

(4) High temperature and high humidity test

mainly test the adhesive force of the sealant, the water vapor transmission rate, and the effective adsorption capacity of the molecular sieve. The samples were subjected to 224 cycles under high temperature and high humidity test conditions (humidity > 95%, the temperature varied regularly between 25 and 55 °C). In each cycle, the gas in the insulating glass has to undergo an expansion and contraction, so there is a higher requirement for the adhesive force of the sealant. In addition, due to the high humidity, the water vapor transmission rate of the sealant should be low, and the molecular sieve should have a strong adsorption capacity.

(5) Climate cycle test

To test the anti-aging ability of insulating glass, it is an investigation of the comprehensive performance of insulating glass. It stimulates the four-season climate (cold, hot, wind, and rain) in a year. Each cycle has to go through 3 stages heating, natural cooling, and forced cooling, and a total of 320 cycles are carried out. The easy problem during the inspection is that the insulating glass bursts and final dew point rise. As a deep-processed product of glass, insulating glass is expensive. Once it is damaged after installation and use, it is difficult to replace and the cost is high. Therefore, the raw materials of insulating glass should be carefully selected, and the production process should be carried out in strict accordance with the operating procedures. Only in this way can the overall production quality of insulating glass be improved.

2.2 Development direction of complete sets of processing equipment for insulating glass

The good performance of insulating glass is gradually recognized by glass buyers, and its penetration rate is getting higher and higher. The deep processing equipment of insulating glass should develop in the direction of a high degree of automation, stable product quality, good energy saving and heat insulation effect, and long service life.

(1) Online Low-E glass film removal machine

Because of the current application of coated glass such as Low-E Glass and solar control film in the hollow market, the glass film layer must be removed at the butyl coating, otherwise, the service life will be affected, so the surface film must be removed mechanically. The recommended parameters for the film removal wheel of the automatic film removal line are air pressure 0.8~1.2 MPa, rotation speed 1 8007 900 r/min; the grinding wheel is made of emery or stainless steel wire below 0.15mu (100 mesh). There is no residual trace on the surface after removing the film. The development direction is to set the grinding wheel pressure according to different film systems.

Figure 2 The LIJIANG online Low-E glass film removal machine

(2) Online chamfering machine

At present, much insulating glass is inlaid inside the window frame, and the glass edge grinding requirements are not high. However, to prevent edge cracks and residual stress, it is necessary to grind the edges and corners on both sides. The online chamfering machine is characterized by its high speed and efficiency. Soon to be applied to the hollow wire group line. The speed of chamfering should be strictly controlled, usually by frequency control. The speed of the high-speed chamfering machine can reach more than 10 000 r/min, and the chamfering size is 0-6 mm, which can be adjusted. At present, there are mainly two types of grinding wheels and abrasive belts, each with its advantages. The key is how to prolong the service life of the grinding wheel and realize the adjustable chamfer angle and online special-shaped chamfer under the condition of high speed.

(3) Vertical washing and drying machine

It is required that Low-E glass, thin film photovoltaic glass, and ordinary float glass can be cleaned. It is an efficient glass washing equipment, which integrates glass washing and drying. It can be used for washing and drying before manufacturing insulating glass to ensure insulating Glass clean surface. During research and development, attention should be paid to the material, diameter, conductivity of pure water, parallelism, and material of the roller brush, and electric heating and hot air devices should be provided. When processing, it is necessary to use 5 MQ or more deionized water, use it when heated to 30 °C, and control the speed of the roller brush, the pressure and angle of the air duct, and the return water at the outlet from the details.

Figure 3 The glass washing and drying function from LIJIANG Production Line

(4) Automatic bending frame and upper frame, online butyl rubber machine, molecular sieve filling

The equipment involved in this process should meet the needs of both aluminum frames and stainless steel frames. Online two-component sealant is the mainstream, and attention should be paid to the glue material, pressure, electric heating, etc.

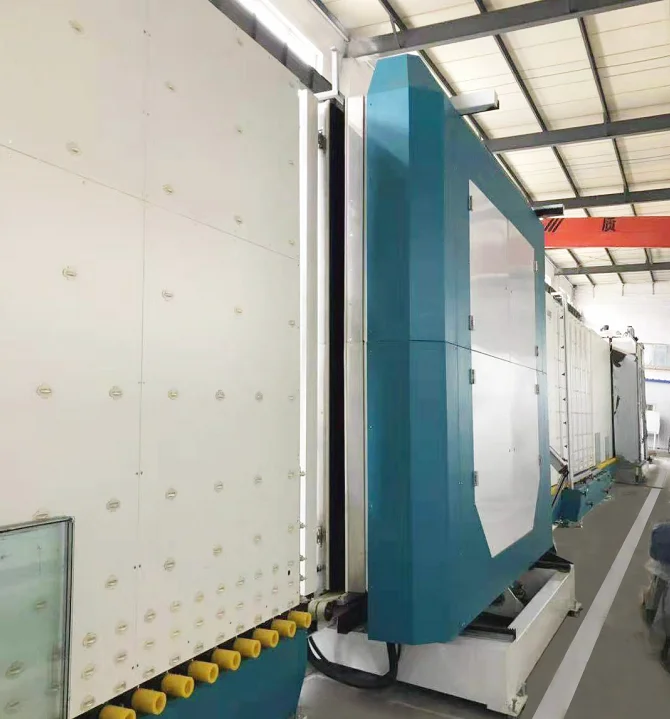

(5) Glass press equipment

There are two ways of internal and external pressing, among which the external pressing is more flexible, and the flatness and pressure of pressing are the keys. The pressing equipment should have the function of vacuuming or adding inert gas online inflation or off-line inflation.

Figure 4 The glass press function of LIJANG Production Line

(6) Online coating machine

Generally divided into one-component and two-component glue machines, mainly use polysulfide glue, the pressure is generally 0.5~0.8 MPa, and the glue depth is 5~10 mm. The two-component gluing machine is generally controlled by digital and analog PLC, and the number is manually input on site according to different insulating glass. The key to research and development is the stability of glue pressure, the control of glue pressure and glue volume at the corners, the improvement of glue dispensing speed, automatic identification of width and depth, automatic glue dispensing, and identification of unequal sides and special-shaped insulating glass.

Figure 5 The LIJIANG online two-component coating machine

(7) Front and rear hanger suction cups

Used for glass edging machines, glass adsorption, and handling tools, there are single-claw suction cups, double-claw suction cups, three-claw suction cups, etc. The suction force of the front and rear hanger suction cups is 500 kg and 1000 kg respectively, which can reduce the operator's handling labor intensity and reduce the number of staff.

Figure 6 The LIJIANG front and rear hanger suction cups

(8) Fully automatic control

The combination of centralized signal control and on-site control of the whole line should be focused on research and development: automatic identification of film system and detection of glass position; automatic detection of hollow thickness and aluminum strip width; automatic adjustment of the lamination pressure according to the hollow size; automatic glue application and automatic identification of glue depth and width. Width, automatic adjustment of glue pressure and flow, program optimization of the in-line frame, and automatic adjustment of pressing pressure.

3. Conclusion

Insulating glass is currently the most widely used deep-processed glass in the construction market. Its manufacturing equipment, the insulating glass production line, is gradually popularized, but most of them are semi-automatic production lines with low stability, efficiency, and quality. Therefore, the fully automatic line in the true sense can not only save a lot of labor, increase production capacity, and improve product quality, but also can upgrade the replacement equipment online (such as adding insulating glass gas filling, vacuuming glass, etc.) R&D and manufacturing are of great significance.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.