LJBZ2535DGF Vertical Insulating Glass 2.5m Air-floating Double Channel Argon Gas Filling Production Line

Compared with the ordinary insulating glass production line, LIJIANG Glass LJBZ2035GF vertical 2.5m air-floating double channel argon gas filling insulating glass production line adopts the air-floating backing plate, which can prevent the glass from being scratched during processing and avoid the contamination of glass roll marks...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJBZ2535DGF Vertical Insulating Glass 2.5m Air-floating Double Channel Argon Gas Filling Production Line

Technical parameter

- Processing glass size: minimum 400 mm * 300 mm, maximum 3000 mm * 2500 mm (length*height)

- Output: 110 pieces/hour

- Original glass thickness: 3-12 mm

- Thickness of processing insulating glass: maximum 50 mm

- Power supply: 380 v, 50 Hz

- Total power: 44.3 Kw (including heating power 16 kw)

- Working direction: the right to left is the positive direction - the operator faces the front of the device (the direction can be requested by the user).

- Working speed: cleaning speed: 3-9 m/min, transmission speed after cleaning: 15-45 m/min

- Dimensions: 24000 mm * 2500 mm * 3680 mm

- Total weight: 9500 Kgs

Main performance features

1. Identification of Low-E coated glass

It can identify the film layer of the coated glass, ensure the correct position of the film surface, and avoid unqualified products caused by the wrong position of the film surface.

2. To ensure that the coating layer is not scratched when making the coated insulating glass, three sets of soft brushes are used to work at the same time; the cleaning and drying section shield and the wheel frame are all made of food-grade 404# stainless steel, and the parts in contact with water are made of Stainless steel and other corrosion-resistant materials; high-pressure fans, sealed sound-absorbing materials and circulating air devices not only reduce secondary pollution but also reduce energy consumption and noise, ensuring long-term optimal cleaning effect and service life. The shell of the washing machine is made of stainless steel, and the upper and lower top plates are made of 5 mm thick stainless steel plates.

3. Increase the transmission section, and greatly improve the work efficiency

The conveying section is increased to two sections, which can store more glass after cleaning, avoiding the production bottleneck caused by the slow cleaning speed, and thereby improving production efficiency.

4. Energy-saving intermittent automatic work

When the glass runs to the end of the lamp inspection section and stops, the brush and the water pump also stop working, the fan damper is closed and the power is reduced to a minimum. After the front glass is assembled, the brush, water pump, and fan will automatically return to normal work.

5. Reasonable aluminum strip positioning design

The glass is stopped and positioned at the end of the positioning section of the aluminum frame, that is, the aluminum bars are placed. The side positioning and lower positioning of the aluminum frame are manually and steplessly adjustable, and the scale is displayed, which is convenient for adjustment. In addition, while the glass on the segment is automatically combined, aluminum bars can be placed in the positioning segment of the aluminum frame, which greatly reduces the average production time of each piece of glass and improves production efficiency.

6. Automatic detection of glass height

The segmented lifting beam is equipped with a glass detection device, which always stops at a position 10cm above the glass, without having to go up and down every time, which greatly improves the speed of splicing. The positioning of the second piece of glass on the combined segment is accurate, and it is completed by the manipulator, which does not require manual push to assist with the positioning, and truly realizes the automatic combination.

7. Externally combined double insulating glass

According to production needs, in addition to making single-layer insulating glass, it can also automatically combine double-layer insulating glass in the splicing segment to meet market demand and increase market competitiveness.

8. Secondary plate pressing

When the length of the glass is greater than the length of the plate pressing section, secondary pressing can be performed. The plate pressing surface can be fine-tuned.

9. After the plate pressing section is a vertical conveying section

After the plate is pressed, the next section is a vertical conveying section, which is convenient to connect with the automatic gluing machine and improve the automation degree of the equipment.

10. Touch screen monitoring and display system, automatic diagnosis of equipment failure

Equipped with a 10.4-inch touch screen man-machine interface, it can automatically display the production process of insulating glass and the operation of the equipment, and automatically diagnose equipment failures. The system is set with a pause function. When there is a problem with the glass, press the emergency stop button, put the glass in its original position after processing it, turn on the emergency stop button, and press the reset button, and the system will return to its original working state. Improve work efficiency and reduce labor intensity.

The Air-floating Glass Transmission Section

At present, with the development of technology and market demand, the insulating glass format of glass curtain wall buildings continues to expand and its thickness continues to become thinner. Therefore, the production technology of the insulating glass automated production line is required to be higher. At present, large-sized hollow front flat glass is mostly transported by contact transmission rollers. These contact methods can easily cause scratches and contamination to the flat glass, and can easily cause the glass to break, thus seriously affecting the quality of the product and thus the production efficiency.

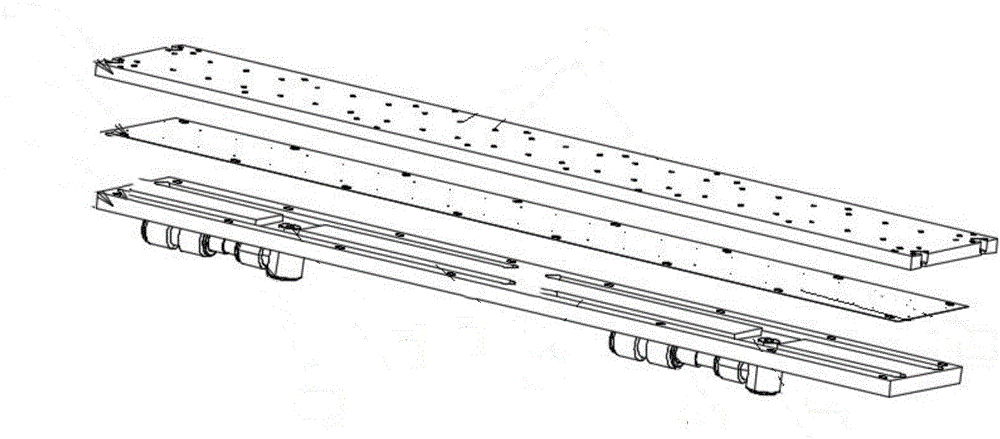

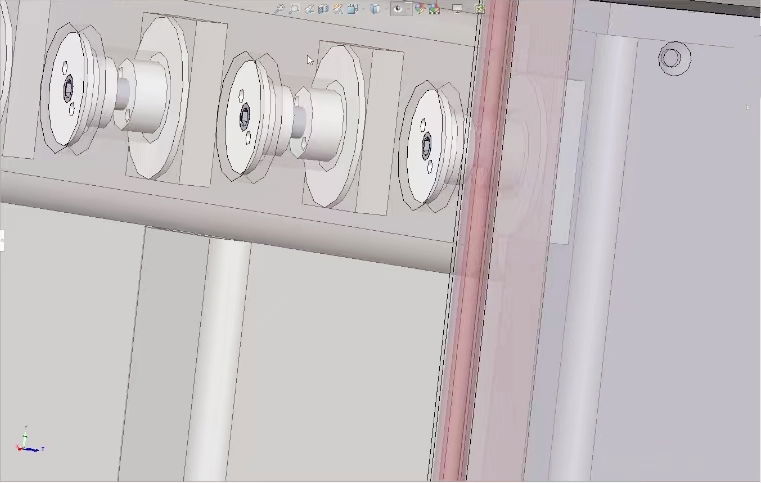

Figure 1 The Air-floating Glass Transmission Section 1

Figure 1 The Air-floating Glass Transmission Section 1

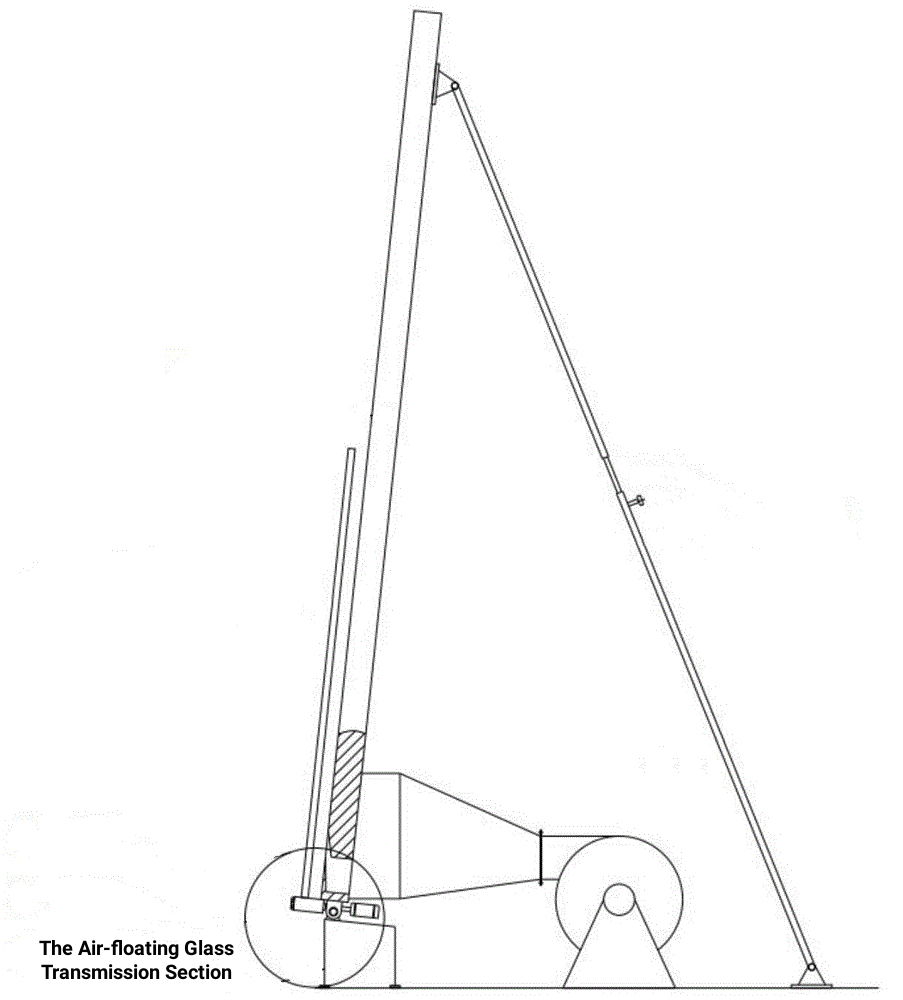

Based on the phenomena of scratches and contamination that often occur among glass deep processing practitioners, LIJIANG Glass independently developed and produced an air-floating glass transmission section, which is used for air-floating transportation of large-scale glass, including a bracket and an air-floating transportation platform installed on the bracket. , the air flotation conveying platform is assembled and spliced by several air flotation conveying plates; several floating holes are distributed on the air flotation conveying plate, and a conveying channel is opened inside the air flotation conveying plate, and the conveying channel runs through the side of the air flotation conveying plate, Each of the floating holes is connected to a transportation channel inside the air flotation transport platform; the floating holes are in the shape of a funnel with an upward opening, and diversion grooves are evenly provided around the edges. The new air-floating glass transmission section has a simple structure, easy processing, and flexible operation. Through airflow control, specific airflow distribution can be achieved to achieve air-floating lifting with uniform lifting force, stable load-bearing of large glass, and convenient transportation.

Figure 2 The Air-floating Glass Transmission Section 2

Figure 2 The Air-floating Glass Transmission Section 2

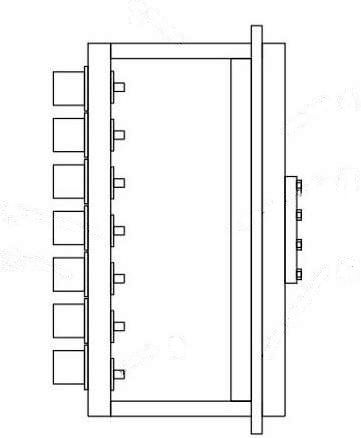

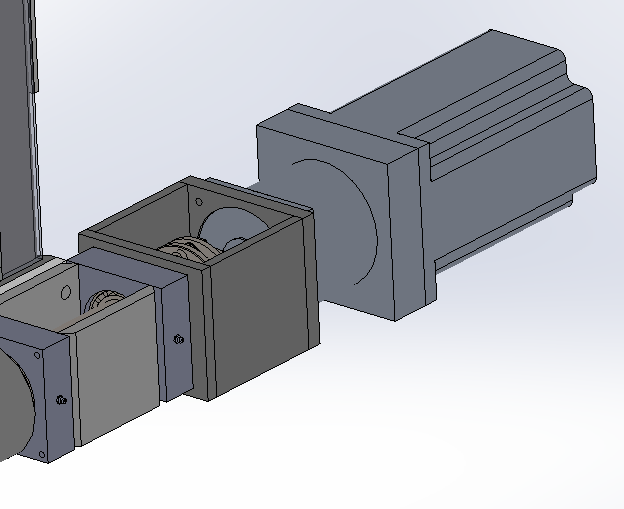

The External Plate Pressing Structure Section

Most of the insulating glass plate pressing structures currently in use use ball screws and hydraulic pressure. In the actual production process, most of the production line equipment and transportation structures require the insulating glass to be transported at an angle, resulting in subsequent plate pressing. The structure is also tilted. After long-term use, the plate-pressed structure is prone to metal fatigue, causing the insulating glass to collide with the plate-pressed structure, causing fragmentation and delaying the production progress. Secondly, during the subsequent plate pressing process, the hydraulic pressure The mechanism and ball screw are easily prone to stroke deviation, resulting in uneven subsequent plate pressure, which may lead to loose sealing or fragmentation.

In response to this problem, LIJIANG Glass independently developed and produced an automated insulating glass outer sheet pressing production line using a plate pressing device. Through storage boxes, buffer rods, buffer springs, mounting blocks, balls and negative pressure suction cups, it can ensure During the process of extrusion and transportation, the insulating glass is in a relatively stable state and will not be dislocated, which avoids the problem of loose sealing and improves the quality stability of the product. Through the limiting frame, limiting rollers, plate surface and base, The working stroke of the limiting plate can be limited to avoid the problem of uneven force, which may lead to broken insulating glass or loose sealing.

Figure 3 The External Plate Pressing Structure Section 1

Figure 3 The External Plate Pressing Structure Section 1

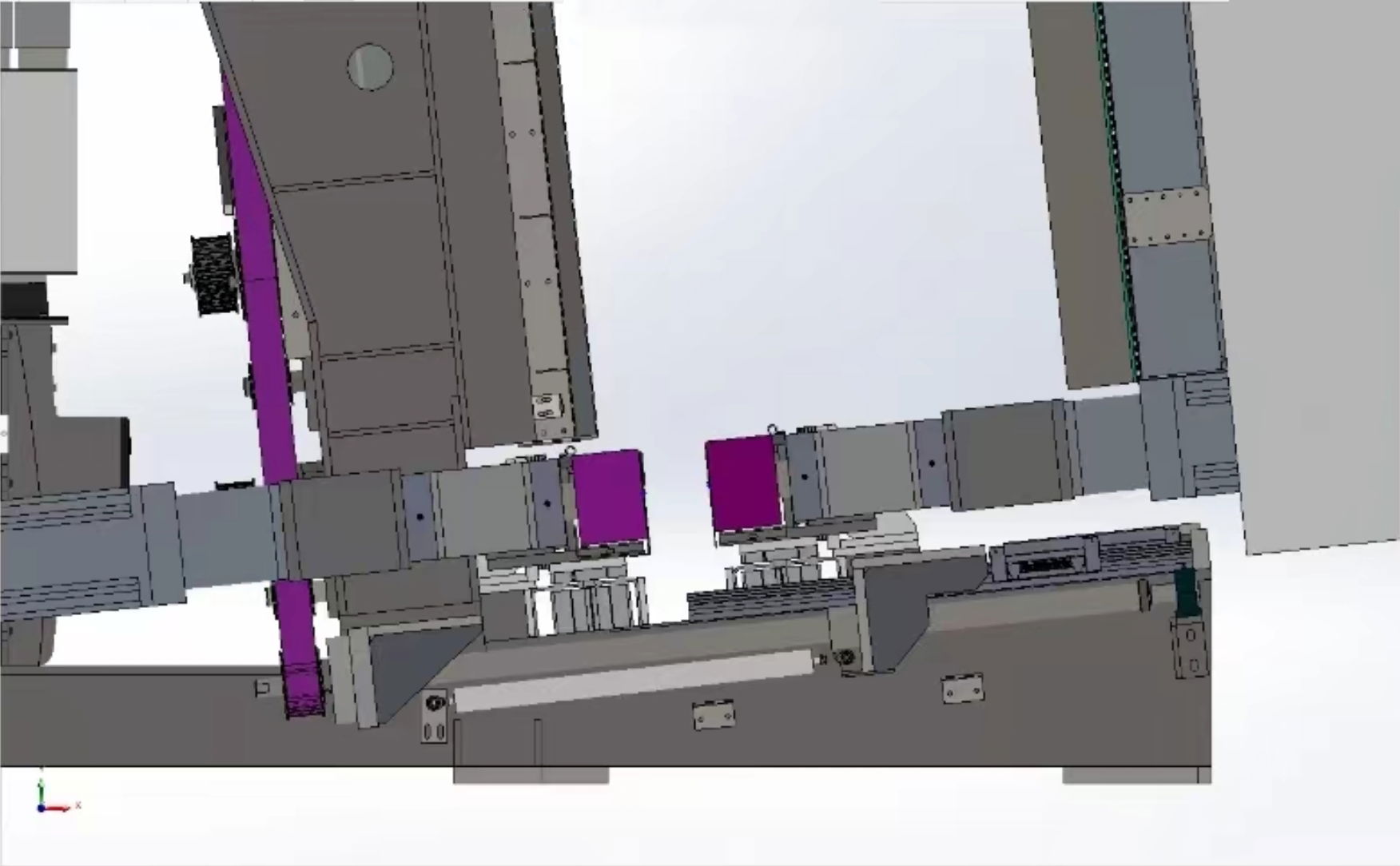

Figure 4 The large piece of laminated glass + small piece of laminated glass can be dragged and combined separately

Figure 4 The large piece of laminated glass + small piece of laminated glass can be dragged and combined separately

Figure 5 The plate pressing section can be adjusted in sections to avoid deformation caused by multiple plate pressing at the same position.

Figure 5 The plate pressing section can be adjusted in sections to avoid deformation caused by multiple plate pressing at the same position.

Figure 6 The glass lifting of the plate pressing section adopts synchronous belt transmission instead of roller transmission

Figure 6 The glass lifting of the plate pressing section adopts synchronous belt transmission instead of roller transmission

Figure 7 Using high-power Siemens servo motor + driver to drive the plate pressure structureImage caption

Figure 7 Using high-power Siemens servo motor + driver to drive the plate pressure structureImage caption

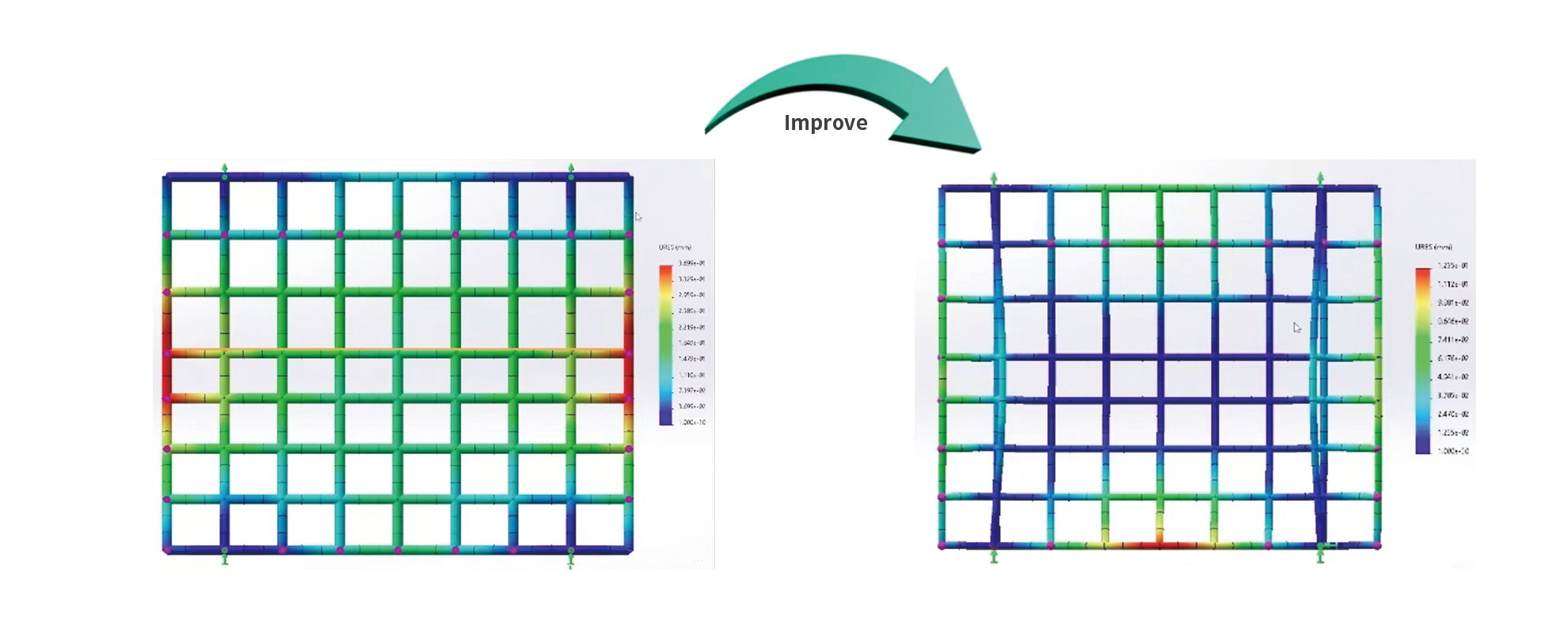

Figure 8 Simulation check, improve the plate pressure section based on actual test results;Remove stress, and extend the service life of the plate pressure section

Figure 8 Simulation check, improve the plate pressure section based on actual test results;Remove stress, and extend the service life of the plate pressure section

Video 1 The inflatable section display: naturally inflated from bottom to top

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Frequently Asked Questions about Screw Plate Pressure Section of Insulating Glass Production Line.

Reason: The plate pressure counting switch did not count.

b. Failure: After the plate pressure enters the front piece of glass, the side positioning structure is not lifted, and the glass stops inside the plate pressure after part of it comes out. The plates are pressed together and held up by the lower positioning.

Reason: Manually check whether side positioning is working.

c. Failure: After the plate pressure entered the front piece of glass, the side positioning structure did not lift, and the plate pressure conveyor wheel did not stop after part of the glass came out.

Reason: Check the plate pressure internal detection switch.

d. Failure: After the plate pressure enters the front piece of glass, it does not come back after the pressing is completed, and the sound of the suction cup closing is not heard.

Reason: Check the micro switch in the smaller area inside the plate pressure.

e. Failure: The 1800 screw-type production line does not stop when the reference process is in place.

Reason: When returning to the screw line, the plate pressure must be opened past the plate pressure deceleration switch point before returning to the reference. Check whether there are signals from the proximity switches of the reference point and deceleration point during the reference return process.

f. Failure: It has been used for a period of time, and the detection glass is not cleaned after the glass is cleared out of the cleaning section.

Reasons:

1. Check whether the water quality is clean and replace the water. Clean the fan inlet filter.

2. If it is in the shape of uniform horizontal strips, check whether there is any dirt on the surface of the last rubber roller.

3. If there are oblique marks on the surface, check whether there is a gap in the middle of the last rubber roller, and adjust the rubber roller bearing seat spring if necessary.

g. Failure: The glass was broken during the pressing process of the plate. Reason: There are many factors involved in broken glass during the plate pressing process. The reasons should be found based on the actual situation.

Reasons:

1. The suction cup cannot hold the glass. Adjust the air pressure controlling the suction cup to 7-8MPa, and check whether the suction cup in contact with the glass is working. If not, adjust the solenoid valve and the microswitch of the corresponding suction cup.

2. The hydraulic pressure is too large. Adjust hydraulic pressure.

3. The pressure plates before and after plate pressing are not parallel. Adjust the front pressure plate.

4. There are high points in the plate pressure, mainly due to glue or other foreign matter. Clean up.

h. Failure: glass misalignment.

Reason: The misalignment of the glass is mainly due to the change in the size or speed of the glass causing the glass to not hit the position. Adjust the delay time in the touch screen. If it is a 1600 production line, adjust the deceleration time of the inverter.

i. Failure: The plate pressure section cannot absorb the glass.

Reasons:

1. Check the air pressure.

2. Check the solenoid valve that controls the suction cup and the corresponding micro switch.

j. Failure: After the finished glass product is pressed, the side positioning is opened during the removal process.

Reason: Check whether the facade of the flip section is higher than the plate pressure and whether the universal wheel affects the glass when the glass is coming out. Adjust flip segments.

k. Failure: After the glass-pressed product is completed, the plate pressure does not return.

Reason: Check whether the finished product in place switch behind the plate press is on.

l. Failure: After the glass-pressed product is completed, the plate press takes a long time to return.

Reason: Check the finished product in place switch behind the plate pressure.

m. Failure: After the glass-pressed product is completed, the turning table does not transport, and the plate-pressing section does not rotate either.

Reason: Check the travel switch and photoelectric switch behind the turning table. Check the limit switch of the turning table when it is turned in place. ,

n. Failure: The motor does not rotate.

Reason: Check manually. If it does not turn on, check whether the circuit breaker in the electric control box has power.

o. Failure: After the front piece of glass is pressed, the second piece rushes out, and the conveying of the plate pressing section stops.

Reason: The glass does not touch the plate pressure counting switch and adjust the switch. Do not touch the counting switch with your hands when installing the aluminum frame.

p. Failure: After the front piece of glass is pressed, the second piece rushes out, and the plate pressing section still does not stop.

Reason: The glass does not touch the detection switch behind the plate pressure section, adjust the switch.

q. Failure: After the screw line plate is pressed against the front glass, the plate pressure crashes.

Reason: The main reason is that the actual opening distance of the plate pressure does not match the servo setting, or the actual thickness of the glass does not match the machine setting thickness. First, adjust the glass thickness. You can increase the glass thickness setting. If the difference is large, you need to adjust the reference point position setting in the plate parameters.

r. Failure: A certain section of the production line is no longer driving, and the inverter generates a start emergency signal. Reason: Check according to the inverter startup emergency signal information, see the inverter manual. Check the equipment according to the instructions. If it is overloaded, you need to maintain the bearings of the equipment and check whether there are any damaged bearings. It can be reset by pressing the SHOP key on the inverter.

s. Failure: The cylinder in the plate pressure section does not work.

Reason: You can check manually first. If the working instructions indicate that there is no problem with the circuit part. If there is a problem, check the solenoid valve and use the manual switch of the solenoid valve itself to check. If there is no action, there is a problem with the mechanical part of the cylinder itself. If there is any movement, replace the solenoid coil and test.

t. Failure: The machine program is disordered.

Reason: The regulations were not implemented during the operation. Turn off the main power supply and then restart it.

u. Failure: The glass deviates during operation, causing the small glass to fall or the switch cannot be detected.

Reason: Manually slow down the speed, check which wheel the glass is deflecting from, and adjust the wheel.

v. Failure: The glass comes out of the cleaning box and the second half cannot be blown dry.

Reason: The speed of segment 03 is faster than the cleaning speed, so adjust it slowly.

w. Failure: The plate surface before and after plate pressing is uneven, resulting in broken glass or an excessive difference in glass flatness.

Reason: Mainly caused by transportation or assembly. If you need to fine-tune the hydraulic line, you only need to adjust the adjustment screws on the four sidebars behind the plate pressure. If larger adjustments are needed, loosen the tightening connecting sleeves on the four corner gears, press the front and rear plates flat until there is no gap, and then tighten the connecting sleeves. If it is a screw cable, you need to remove the chain surrounding the plate pressure screw, make the front and rear plate surface flat, and then connect the chain.