Electric Intelligent Glass Lifter Loading Suction Cup Car

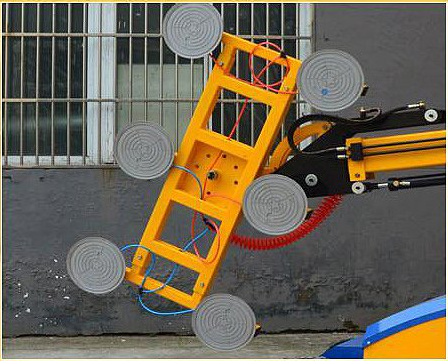

The electric glass handling suction cup car, it can realize electric walking without an external air source or power supply during the using. It has functions such as electric lifting and lowering, electric suction and deflation, manual rotation 360°, and manual flip 90°. The suction cup car comes with a vacuum pressure supplement system to ensure that the vacuum system maintains a relatively constant safe pressure value during the entire glass handling process. After an accidental power failure, the pressure maintenance function can prolong the emergency processing time and ensure safe use.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LIJIANG Glass Electric Intelligent Glass Lifter Loading Suction Cup Car

Details Display

It is mainly used for glass handling equipment, used in glass production and processing, glass curtain wall, construction site engineering glass installation, etc. The glass installation machine is suitable for handling insulating glass, tempered glass, glass curtain wall, glass transfer in the glass deep processing workshop, etc. The use of glass trucks for glass handling can not only greatly reduce the injury rate in glass building installation projects, but also improve the production efficiency in the process of material handling and installation, and save labor costs.

Electric Intelligent Glass Lifter Loading Suction Cup Car 1

Electric Intelligent Glass Lifter Loading Suction Cup Car 1

Benefits & Advantages

300mm suction cups

Imported silica gel suction cups are used, and the suction cups have three layers of sealing rings. The sealing performance is good, the material is soft, environmentally friendly and odorless, easy to clean, and has a long service life. It is suitable for glass curtain wall installation and glass deep processing and handling industries. And also, The high wear-resistant nitrile rubber suction cup is optional.

Imported silica gel suction cups

Imported silica gel suction cups

Adopts a dual control system

It adopts a dual control system of manual rocker and numerical control button handle, equipped with an air pressure gauge imported from Japan, and an air pressure pump imported from Europe, with stable quality and high safety performance.

The design of the remote control handle

The design of the remote control handle is humanized and suitable for a variety of workplaces

The design of the remote control handle

The design of the remote control handle

The wear-resistant outdoor drive wheels

Wear-resistant outdoor drive wheels, high-power motor, powerful power, solid wear-resistant front wheels, suitable for various occasions and outdoor operations

The wear-resistant outdoor drive wheels

The wear-resistant outdoor drive wheels

The design of multi-layer rocker

The multi-layer rocker design is used to facilitate the electric flipping of the glass panel

The design of multi-layer rocker

The design of multi-layer rocker

The design of side support legs

The design of side support legs can better maintain the stability of the body and ensure the safety of use

The design of side support legs

The design of side support legs

DIgital display

The negative pressure vacuum air circuit is adopted, and the negative pressure digital display is displayed. Compared with the traditional instrument display, the sensitivity is improved and the display is more accurate and intuitive, ensuring glass suction to a certain extent.

And with insufficient pressure alarm and automatic supplementary negative pressure, digital display vacuum pressure, and battery power gauge, you can monitor the operation of the equipment more clearly Ultra-high sensitivity, including a pinhole 1/10 the size of the leak can be on the digital display.

Intuitive display

The digital display is built into the operating electric cabinet, which can better protect the equipment from the impact of the harsh engineering environment and the damage caused by accidents. It is suitable for outdoor construction and installation of engineering glass.

Equipment performance

The frame is made of national standard materials, and the suction cup has high-temperature resistance and strong suction. It has high adsorption force when it touches a smooth surface and is easy to operate.

Electric Intelligent Glass Lifter Loading Suction Cup Car 2

Electric Intelligent Glass Lifter Loading Suction Cup Car 2

More Details of Glass Lifter Loading Suction Cup Car 1

More Details of Glass Lifter Loading Suction Cup Car 1

More Details of Glass Lifter Loading Suction Cup Car 3

More Details of Glass Lifter Loading Suction Cup Car 3

More Details of Glass Lifter Loading Suction Cup Car 4

More Details of Glass Lifter Loading Suction Cup Car 4

The Using Instructions

1. The glass suction cup lifts and starts

Turn on the power switch on the control box, start the vacuum pump, and first evacuate the air in the accumulator to ensure sufficient vacuum, when the pressure is lower than 50%, the sound and light alarm lamp will alarm until the required vacuum pressure is reached. When the pressure reaches the set pressure, the vacuum pump will automatically stop running to save power. At this point, the vacuum lifter is in a ready state.

2. Glass suction cup positioning

Control the movement of the lifting equipment so that the suction cup of the suction hoist is close to the glass surface. At this time, the suction cup of the suction hoist is fully fitted and sealed with the glass surface;

3. Glass adsorption

Push the manual hand slide valve on the operating handle. At this time, the suction cup is connected to the vacuum system, and the suction hoist automatically absorbs the glass. The vacuum pressure gauge will display the vacuum degree (pressure) at this time. When the pressure gauge shows that the vacuum degree reaches 55%. (-0.55kg/f), it means that it can be transported, and this process takes about 2-3 seconds;

4. Glass flipping:

Pull out the locking shaft pin, and push the suction cup holder hard, so that it can drive the workpiece to turn upwards until it reaches the position of about 90 degrees, the shaft pin will automatically lock the suction cup holder, and at this time, the workpiece can be turned 90 degrees vertically.

Electric Intelligent Glass Lifter Loading Suction Cup Car 3

Electric Intelligent Glass Lifter Loading Suction Cup Car 3

Main Technical Parameter

| Item. | Spec. |

| Power | 0.37KW (50Hz) |

| Vacuum pressure | -0.05~-0.08Mpa |

| Power-off holding time | ≥20min |

| Vacuum pressure dropped from | -0.08 Mpa to -0.045 Mpa |

| Suction lift Z small glass size | 600 mm * 800 mm |

| Suction glass size | 4000 mm * 6000 mm |

| The number of suction cups | Could 4 cups to 12 cups |

| Suction weight | 300kg |

| Glass installation robot | LJXPC | ||||

| Load capacity(kg) | 300 | 350 | 400 | 500 | 600 |

| Manual rotating(°) | 360 | 360 | 360 | 360 | 360 |

| Lifting height(mm) | 3500 | 3500 | 3500 | 3500 | 3500 |

| Manipulation | Walkie Type | ||||

| Battery(V/A) | 2*12/80 | 2*12/90 | 2*12/100 | 2*12/120 | 2*12/120 |

| Charger(V/A) | 24/12 | 24/12 | 24/15 | 24/18 | 24/18 |

| Drive motor(V/W) | 24/1200 | 24/1200 | 24/1200 | 24/1500 | 24/1500 |

| Lift motor(V/W) | 24/2000 | 24/2000 | 24/2000 | 24/2200 | 24/2200 |

| Overall width(mm) | 810 | 810 | 810 | 810 | 810 |

| Overall length(mm) | 2660 | 2660 | 2660 | 2800 | 2800 |

| Driving wheel dimension(mm) | 250*80 | 250*80 | 250*80 | 300*100 | 300*100 |

| Pads diameter(mm) | 300 | 300 | 300 | 300 | 300 |

| Glass size(mm) | 3660*2440 | 3660*2440 | 3660*2440 | 3660*2440 | 3660*2440 |

Package and Shipping

The Package Process of Glass Lifter Loading Suction Cup Car 1

The Package Process of Glass Lifter Loading Suction Cup Car 1

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.