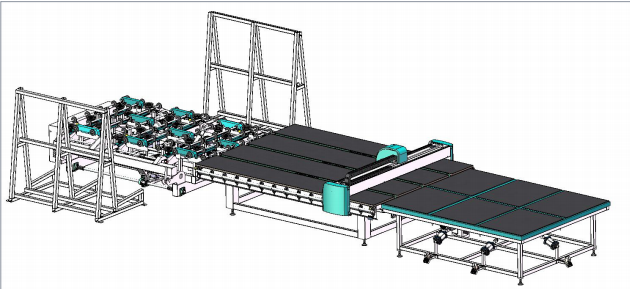

CNC2620 Automatic Glass Cutting Machine Cutting Line with Breaking Table

LIJIANG Glass CNC2620 Cutting Machine, which is the type of fully automatic high-speed glass cutting line, is composed of three parts: automatic loading table, automatic glass cutting machine and automatic breaking table, realizing the assembly line operation of loading, cutting and breaking.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

Equipment Overview

1. Motion controller

1) The movement speed is fast, the action is stable, the control precision is high, and the controller is modularized.

2) The human-machine interface is simple and elegant, and parameter adjustment is simple.

3) Photoelectric positioning cutting mode, direct cutting mode, oil-free cutting mode, automatic/blank mode switching can be realized at any time during glass processing.

4) Library nesting programming, select the special shape from the library, set the relevant parameters, and the glass processing quantity can be directly nested and cut.

5) The complete glass pressure library is stored, and the cutting pressure of various thicknesses can be input and saved at one time, and can be called directly next time.

6) Real-time tracking and display of processing path, timely recording of motion coordinates, axis status, I/O status, fault diagnosis and automatic alarm recording.

7) It supports a variety of processing file types, accepts standard G codes of nesting software such as Optima and Guiyou, and DXF format files of AUTOCAD. The graphics editing software that comes with the system can adjust the direction of the tool path and delete line segments.

8) Various protections: including soft limit, cutting limit, external emergency stop, etc.

2. Optimize the software

1) The optimization results done in the office can be imported, and the optimization in the office in advance can save time and improve efficiency.

2) The cutting order can be manually edited

3) A variety of glass original sheets and small sheets can be optimized at the same time

4) Optimized typesetting without size limitation, optimized results, rotation and mirror management and other practical functions

5) Priority management for optimization of cutting small pieces of glass

6) Priority management of glass original sheet optimization

7) Original glass inventory management

8) A variety of efficient optimization algorithms

9) Cutting graphics can be edited

10) Label design and label printing

11) The optimization result report is clearly printed

12) Supports the import of Excel data files

13) The special-shaped glass cutting library contains more than 350 parametric graphics, including all commonly used graphics for glass cutting.

14) Software operation with multiple language options

Equipment Pictures

LIJIANG Glass CNC2620 Cutting Machine 1

LIJIANG Glass CNC2620 Cutting Machine 1

LIJIANG Glass CNC2620 Cutting Machine 2

LIJIANG Glass CNC2620 Cutting Machine 2

LIJIANG Glass CNC2620 Cutting Machine 3

LIJIANG Glass CNC2620 Cutting Machine 3

LIJIANG Glass CNC2620 Cutting Machine 4

LIJIANG Glass CNC2620 Cutting Machine 4

LIJIANG Glass CNC2620 Cutting Machine 5

LIJIANG Glass CNC2620 Cutting Machine 5

Equipment Configuration

| Object / Parts Name | Manufacturer Brand / Trademark |

| Optimization Software | Optima |

| Cutting Software | EOS-NC |

| Servo Motor | YASKAWA |

| Proportional Electromagnetic | SMC |

| Inverter | Delta |

| Touch Panel | Delta |

| Programmable Controller | Delta |

| Photoelectric Switch | Otonmic / Mibo |

| Proximity Switch | Mibo |

| Middle Relay | IDEC |

| Motor Circuit Breaker | Schneider |

| AC Contactor | Schneider |

| Gear Motor | BFL |

| Air Cylinder | XingYu |

| Bearing | NSK / HRB |

| Spline and Gear | Lead Rack |

| Bezel Panel | Density Doard |

| Table Board | Industrial Blankets |

| Centrifugal Fan | SN |

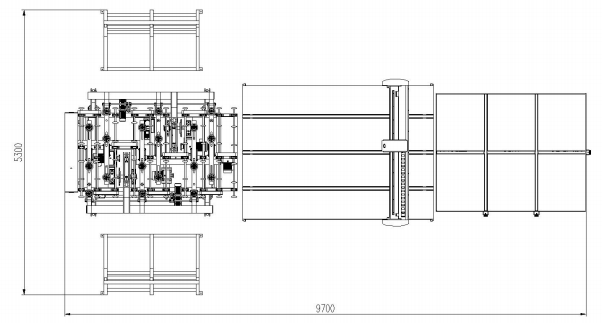

Equipment Appearance Diagram

Equipment Appearance Diagram of Glass Cutting Machine 1

Equipment Appearance Diagram of Glass Cutting Machine 1

Equipment Appearance Diagram of Glass Cutting Machine 2

Equipment Appearance Diagram of Glass Cutting Machine 2

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

11 Common Problems of Full-automatic Glass Cutting Machines

Troubleshooting method: (1) Open the cover of both sides of the panel; (2) Loosen the tension sleeves on both sides; (3) Adjust the tightness of the timing belts on both sides to be consistent.

2. The cutting line is not transparent and cannot be broken: it may be caused by the wrong angle of the cutter wheel or the knife pressure being too small. Troubleshooting methods: (1) Adjust the angle of the cutter wheel; (2) Replace the appropriate cutter wheel.

3. The edge of the cutting line is broken: the possible reason is that there is no oil injection or the cutting pressure is too high. Troubleshooting methods: (1) Fill oil; (2) Reduce knife pressure.

4. The cutting size of the fully automatic glass cutting machine becomes larger or smaller. Troubleshooting method: Adjust the settings of the cutting machine driver.

5. No floating function: It may be caused by the blockage of the air path, damage to the fan, or blockage of the air source triple. Troubleshooting method: (1) dredge the air path and triple parts; (2) replace the fan.

6. Cannot return to the mechanical origin. It may be that the proximity switch for returning to the mechanical origin is damaged. Troubleshooting method: Replace the origin switch.

7. Positive and negative limits are not allowed. Reason: The positive and negative limit switches are damaged. Troubleshooting method: Replace the limit switch with a new one.

8. The computer cannot find the board (hardware). Usually caused by poor contact on the board. Troubleshooting method: Take out the board from the PCI slot and reinsert it tightly.

9. Multifunctional glass cutting machine servo overvoltage alarm. It is caused by the wrong connection between the servo motor power supply and the ground wire, as long as the wrong wire connection is corrected.

10. Encoder communication protection. The encoder address book line is weakly welded or broken, just re-solder the encoder line.

11. The servo motor vibrates too much. Reason: The fasteners are loose or the motor is too rigid. Troubleshooting method: (1) Adjust the tightness of the rotating parts; (2) Reduce the rigidity of the servo motor.

9 Methods of Glass Cutting Machine Use and Maintenance

2. The equipment should be kept clean frequently, and the upper and lower guide rails and gear racks should be wiped and refueled every shift.

3. After the equipment is out of service, the computer will shut down the computer and the power supply after saving the data, and prevent non-operators from damaging the equipment and changing the data.

4. Frequently check whether there is any abnormal sound in the moving parts. If any abnormality is found, stop the machine immediately for inspection and eliminate the fault.

5. After troubleshooting and before starting the machine, check whether the cutter wheel returns to the original point, to prevent the beam from rushing out of the guide rail after starting the machine. (Special attention points)

6. The equipment should use clean compressed air to avoid premature damage to the air circuit components.

7. The power supply of the cutting machine should be grounded to prevent leakage.

8. When forming an assembly line with the loading machine and the turning machine, the cutting machine should be 2-5mm lower than the loading machine and 2-5mm higher than the breaking machine.

9. When cutting glass, the cutter wheel must be refueled (kerosene is used), and the lower fuel tank should be checked frequently for lack of oil, and it should be replenished in time when it is lacking.