Automatic Glass Drilling Machine

At present, the cutting tools used by Automatic Glass Drilling Machine to process glass generally use diamond grinding heads, which are matched with the high-speed rotation of the spindle of 24,000 to 40,000 rpm. The actual processing is grinding rather than cutting. With a special grinding head, it can achieve processing functions such as drilling, grooving, one-time upper and lower beveling of ultra-thin glass, precise cutting of special-shaped glass, shape processing, chamfering, etc. The error can be controlled within ±0.02~±0.05mm. And the edge of the glass is not easy to chip or break.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LIJIANG Glass Automatic Glass Drilling Machine

LIJIANG Glass Automatic Glass Drilling Machine fixes the glass pneumatically and drill with the upper and lower, double drill bits. The pneumatic working table for supporting large size glass is equipped with high efficiency and easy operation. It is one of the indispensable machines in modern glass industry.

Equipment Instructions

The automatic glass drilling machine is a machine specially used for glass drilling. It is mainly divided into base, operating table, drill bit, motor, etc. It has a large drilling diameter and a large overhanging space on the machine base. It can drill various sizes of glass. The workbench is low in height and easy to operate. The lower drill bit adopts air pressure speed regulation and the speed is stable. It is an ideal machine for glass deep processing enterprises for glass drilling.

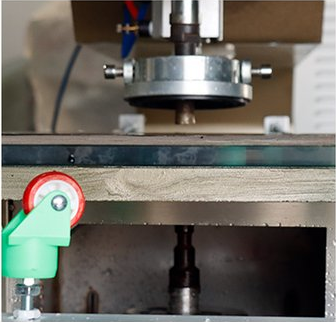

Figure 1 Automatic Glass Drilling Machine

Figure 1 Automatic Glass Drilling Machine

1. When drilling glass, the lower drill bit makes it easy to crush the glass. Therefore, when drilling thin glass, the drilling pressure must be adjusted as low as possible. It can be adjusted in the range of 0.18Mpa~0.3Mpa. When drilling thick glass, the drilling pressure can be increased to About 0.46Mpa.

2. When starting drilling work, you should first inject lubricating oil into each oil injection part, and check the tightness of the belt, whether there are any abnormalities in the operation of the upper and lower drill shafts, and whether the drill bit is worn. Work can only start after everything is normal.

3. The core material in the material receiving drawer should be cleaned in time, otherwise, too much accumulation of core material will jam the material receiving device. Especially when drilling large holes with a diameter greater than 100mm, it should be cleaned every few holes drilled.

4. When cleaning the core material, the material catcher should be in the correct material receiving position so that the material receiving drawer can be pulled out smoothly. When cleaning the core material, the drill bit should be installed before starting the rotation.

PLC controls the drilling program, the glass processing hole diameter is of good quality and the operation is simple.

Figure 2 Double-sided automatic drilling

Figure 2 Double-sided automatic drilling

Three-stage pulley speed regulation to cope with different drilling hole diameters.

Figure 3 High speed motor

Figure 3 High speed motor

Using laser positioning and movable positioning devices, it can be used to adjust the size of glass drilling holes in mass production.

Figure 4 Laser positioning

Figure 4 Laser positioning

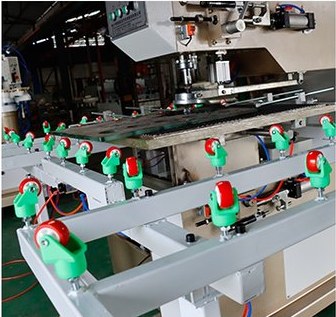

Equipped with a pneumatic lifting worktable, which can be used for drilling and processing of large plate glass.

Figure 5 Automatic lifting platform

Figure 5 Automatic lifting platform

Equipment Precautions

1. Pay attention to safety when debugging and using the glass drilling machine. Workers should not touch moving parts or live parts when the machine is started.

2. Do not place maintenance tools such as wrenches, screwdrivers, and other objects on the conveyor guide rails and hood.

3. In case of an emergency, immediately press the "emergency stop" button or pull down the air switch.

4. Pay attention to the grinding condition of the glass drilling machine at all times, and the grinding wheel loss must be compensated in time.

5. Keep the cooling water in the water tank sufficient and clean at all times to avoid burning the grinding wheel and glass. Clean the grinding impurities in the inlet and outlet pipes in time to keep the water channels open.

6. Before use, check whether the travel switches of all glass drilling machines are working properly and whether the control direction is correct. If the control direction is wrong, stop the machine immediately for inspection, otherwise, direct glass drilling will cause damage.

7. Protect personnel and wear goggles and anti-cut gloves. Clothing that exposes skin is prohibited to prevent cuts.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.