Lavadora y secadora automática de vidrio

Here you can buy your perfect glass washing and drying machine with a fully automatic CNC control system for every need and budget, whether you're a small business owner or a large industrial manufacturer.

Are you doing research on buying affordable vertical or horizontal glass washer and dryer equipment for glass deep-processing with any budget in USA, UK, UAE, Canada, Australia, Russia, South Africa, China, India, or other countries from Asia, Europe, North America, South America, Africa, and Oceania?

Review 2024 best budget automatic glass washing machinery buyer's guide for glass workers, glass processing machinists, glass fabricators, builders, carpenters operators, craftsman, and beginners.

LIJIANG Glass will offer you 2024 top rated automatic insulating glass processing machines with custom CNC glass cutting, washing and drying, loading and unloading, tempering and Laminating, and insulating service to fit your glass processing projects, plans, and ideas in glass produce and process instruments.

Guía de compra de lavadoras de vidrio

La Guía de compra de vidrio de LIJIANG está aquí para usted: allí encontrará nuestras recomendaciones para la última pregunta: ¿Qué tipo de lavadora y secadora automática de vidrio debería comprar? Hay una colección de guías de compra por categoría.

¿Qué es la Lavadora de Vidrio Horizontal?

La lavadora de vidrio horizontal puede limpiar vidrio con un espesor mínimo de 25 mm, y el espesor de limpieza mínimo es de 1,1 mm, que es adecuado para lentes de vidrio, mosaicos de vidrio, etc.; el rango máximo de limpieza de vidrio es de 2500 mm, y el grosor se puede ajustar a 30 mm, que es adecuado para vidrio templado grande, que es vidrio para muebles más grueso, etc.

Know More

Las características de rendimiento de la lavadora de vidrio vertical.

Cuántas características y ventajas tiene la lavadora de vidrio vertical, simplemente desmonte toda la lavadora vertical y analice las características de rendimiento de la máquina de limpieza vertical desde la perspectiva de los sistemas de control mecánico, eléctrico y PLC...

Know More

¿Cuál es la diferencia entre las lavadoras de vasos verticales y horizontales?

La lavadora de vidrio es un equipo especial para lavar y secar la superficie del vidrio antes del procesamiento profundo, como la fabricación de espejos, el revestimiento al vacío, el templado, el doblado en caliente y el ensamblaje de vidrio aislante. Se puede dividir en lavadora secadora de vidrio horizontal y lavadora secadora de vidrio vertical. La lavadora de vasos se compone principalmente del sistema de transmisión, el sistema de lavado y secado, el sistema de control eléctrico, etc.

Know More

¿Cuáles son las características de la lavadora de vasos profesional actual?

Los requisitos de la industria moderna para las máquinas de limpieza de vidrio aumentan constantemente. En el proceso de producción de vidrio industrial, especialmente para el lavado y secado de vidrio, algunos fabricantes de vidrio cuentan con equipos de lavado automático para varios tipos de vidrio. Entonces, ¿cuáles son las características de la lavadora de vasos profesional actual?

Know MoreLavadora de vidrio en venta

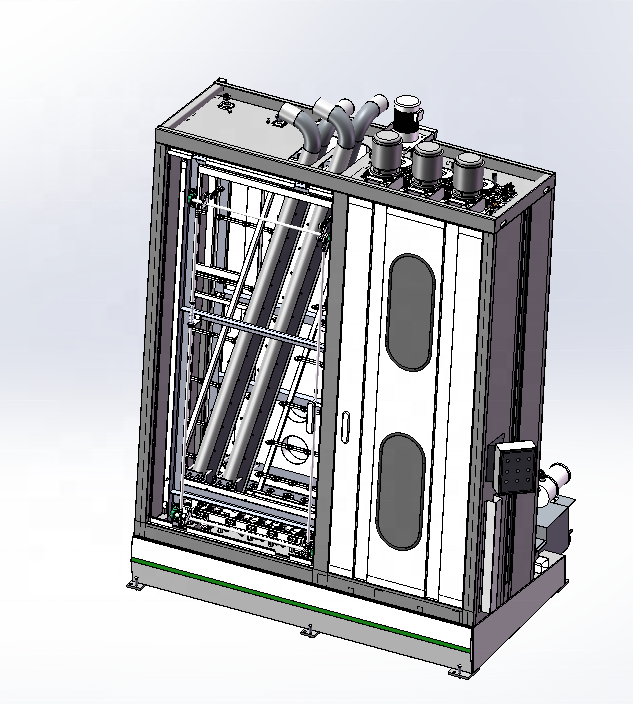

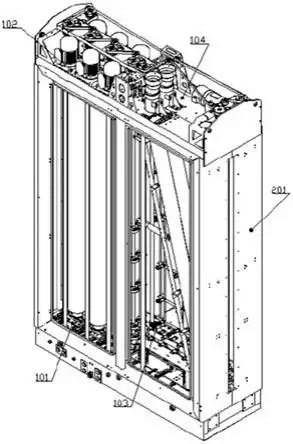

Lavadora y secadora de vidrio vertical

Principio de funcionamiento básico

Know More

Pasos de trabajo detallados

- El cepillo cilíndrico en la parte de limpieza es transportado por una correa independiente del motor. El cepillo está hecho de material resistente a los ácidos y a altas temperaturas de alta calidad, que tiene un buen efecto de limpieza y una larga vida útil.

- Adopta un sistema de transmisión preciso y una regulación de velocidad de conversión de frecuencia, que se puede operar directamente en el panel para ajustar la velocidad de limpieza arbitrariamente.

- Los rodillos de goma transportadores de alta calidad están densamente dispuestos y pueden procesar diferentes tamaños de vidrio. Combinado con la transmisión de engranajes, la transmisión de vidrio es más estable.

- Usando un sistema eficiente de limpieza y secado al aire, el vidrio de diferentes espesores se puede limpiar y secar automáticamente; se limpia con un cepillo, se seca con un rodillo de esponja de alta calidad y luego se seca con aire caliente una vez para garantizar que el efecto de limpieza del vidrio sea limpio y brillante sin dejar rastros de manchas de limpieza.

Saber más

Parámetro técnico

- Tamaño máximo del vidrio: 2000 mm x 2500 mm

- Tamaño mínimo del vidrio: 2500 mm x 3000 mm

- Dirección de trabajo frente al equipo

- Velocidad de lavado: 2-10 m/min

- Espesor del vidrio: 3-15 mm

- Espesor del vidrio aislante: ≤40 mm

- Suministro de agua: 0,5 toneladas/día de agua circulante, conductividad ≤40μS

- Velocidad de lavado: 2-10 m/min

- Altura de trabajo: 580 mm

- Alimentación: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, según DIN 40040

- Humedad relativa del aire: ≤ 75 %, según DIN 40040

Saber más

Descripción técnica

Lavadora y secadora de vidrio vertical

Principio de funcionamiento básico

- Sistema de Autodiagnóstico con pantalla táctil en ordenador.

- Arandela de acero inoxidable con 8 (6) cepillos, cepillos suaves de MONFORTS de Alemania, los cepillos duros se abren automáticamente cuando entra vidrio de baja emisividad.

- Gire la velocidad del control de frecuencia del cepillo. (opcional)

- El cuchillo de aire de acero inoxidable se ajusta automáticamente según el grosor del vidrio, grosor máximo de 19 mm.

- Limpieza de alta velocidad (máx. 14 m/min), bajo nivel de ruido (máx. 70 dB), funcionamiento de alta disponibilidad. (25 segundos/unidad)

- Detección automática de vidrios Low-E y alarma por recubrimiento en reversa. (opcional)

- Estructura escalonada y unidad IG de tres capas disponibles. (opcional)

- Precisión de la prensa de placas: ±0,3 mm

Saber más

Pasos de trabajo detallados

- La lavadora de vidrio puede limpiar vidrio plano común o vidrio revestido con un espesor de 3 a 12 mm;

- El área de limpieza utiliza 3 pares de cepillos u opcionalmente 4 pares de cepillos (o cepillos suaves importados, de recubrimiento o especiales LOE), limpieza con dos o cuatro aguas;

- La máquina adopta una estructura vertical inclinada, el vidrio plano se coloca en el rodillo transportador, pasa por la sección de alimentación, la sección de limpieza y secado y llega a la sección de descarga para completar la tarea de limpieza del vidrio;

- El área de limpieza y el tanque de agua están hechos de acero inoxidable y materiales resistentes a la corrosión; el cuchillo de viento inclinado con viento fuerte puede secar la superficie del vidrio;

- La sección de descarga está equipada con lámparas de inspección para verificar la calidad de limpieza del vidrio. La máquina es fácil de operar y los botones de operación se concentran en la mesa de operaciones.

Saber más

Parámetro técnico

- Tamaño máximo de vidrio: 2000 mm * 2500 mm

- Tamaño mínimo de vidrio: 2500 mm * 3000 mm

- Dirección de trabajo frente al equipo

- Velocidad de lavado: 2-10 m/min

- Espesor del vidrio: 3-15 mm

- Espesor del vidrio aislante: ≤40 mm

- Suministro de agua: 0,5 toneladas/día de agua en circulación, conductividad ≤40 μS

- Velocidad de lavado: 2-10 m/min

- Altura de trabajo: 580 mm

- Potencia: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, según DIN 40040

- Humedad relativa del aire: ≤ 75 %, según DIN 40040

Saber más

Descripción técnica

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More

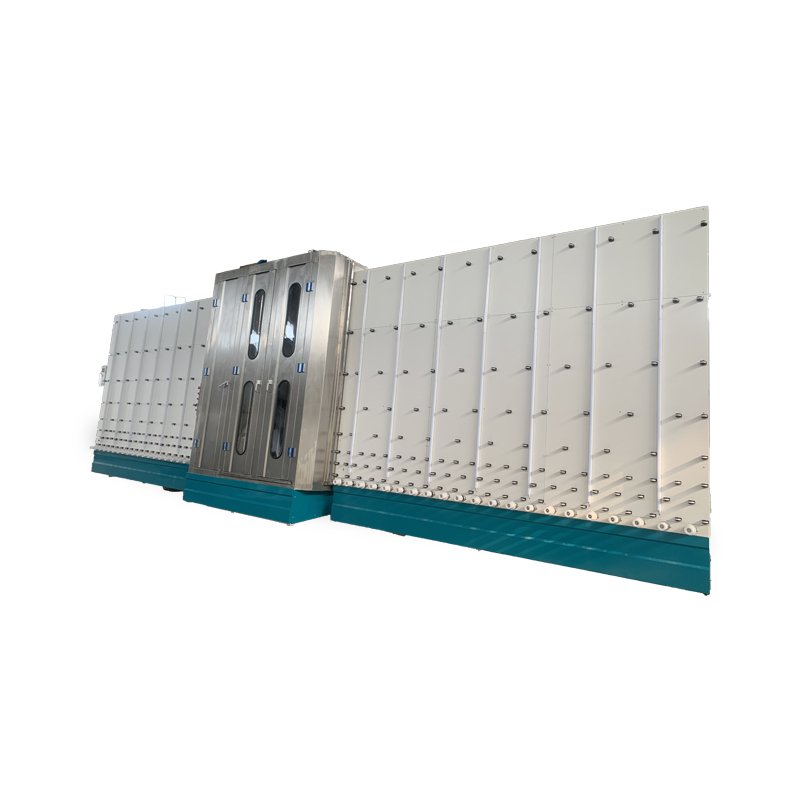

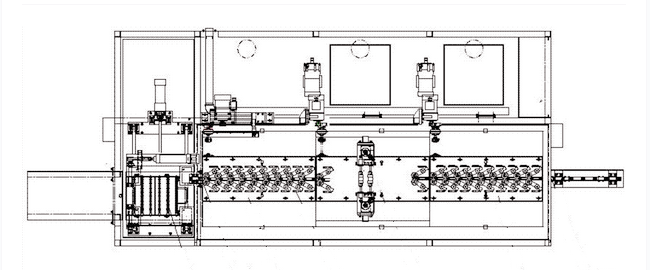

Lavadora y secadora de vidrio horizontal

Principio de funcionamiento básico

Saber más

Pasos de trabajo detallados

1. Aluminum alloy assembled structure, no scrap concept, permanent use,high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift:350 mm,easy to clean and maintain;

6. Three pairs of brush(Ø 150 mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display, the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10. Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11. Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12. Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

Know More

Parámetro técnico

| Item. | Spec. |

| Maximum glass width | 2500 mm (effective maximum: 2650 mm) |

| Minimum glass specification | 400 mm*400 mm (limited to single row on left and right sides) |

| Glass thickness | 3 mm-25 mm (digital display) |

| Speed range | glass thickness within 3-25 mm V max=1-12 m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25 mm |

| Total power | 42 KW(water-bearing wind heating: 15 KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length*width*height) | approximately 6260 mm*4800 mm*3100 mm |

| Weight | 3940 kgs |

Know More

Descripción técnica

The Imported Components

Using imported frequency converter and PLC control system, the speed of entering and exiting the glass can be adjusted freely, and the processing of clear glass can be maintained at a constant speed for a long time.

The 3 Pairs of Rubber Rollers

3 pairs of rubber rollers are used to press the glass sheets, which can achieve the effect of increasing the pressing strength in sequence, and the glass thickness tolerance is smaller than others suppliers.

The High-power Fan

The washing and drying equipment could be equipped with a high-power fan, the drying effect is better, and the cleaning effect of the glass is fully guaranteed.

The Gradient Pressing Method

According to the direction from the glass input to the output, the glass is gradually pressed by using a gradient pressing method. The pressing effect is better than other suppliers.

Know More

Lavadora y secadora de vidrio horizontal

Principio de funcionamiento básico

Saber más

Pasos de trabajo detallados

- Horizontal structure, simple operation. The machine frame adopts heavy thickness aluminum alloy to avoid to be out of shape when working for a longtime.

- With stainless steel water sink and high pressure pre-spraying (high pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps.

- Brush: The top and bottom brushes transmit by 1 motor respectively.

- Water tank (with heater):

- 2 water tanks total, 1 for pre-wash, another for washing section.

- Blower: Low noise and vibration.

- Conveying adopts frequent converter, digital display and convenient operation, which do good to connect with double edging line, hollow glass line, safety glass line, etc. Table rollers adapt superior rubber and transmitted by gear wheel which makes a stable working.

- Side covers and tanks and any other water touched material adopt stainless steel 201.

- Washing and Drying section can be lifted to Max. 400 mm by adjustment on electrical board with 4 legs(corners) increasing through motors and encoder.

- 2 pairs air knives adopt advanced technique device, large power and quick air dry.

Know More

Parámetro técnico

| Item. | Parameter. |

| Max. width | 2500mm |

| Min. size | 400*400mm |

| Glass thickness | 3~28mm |

| Working table height | 900mm±30mm |

| Blower power | 22kw |

| Total power | 32kw |

| Weight | 3000kg |

| Dimension | 5700*3300*2500mm |

| Low-e require | Yes |

| Water heater | Yes |

| Processing speed | 0.5~12m/min |

| Processing-speed suggestion as follow: | |

| 4mm~8mm thickness, speed suggested to 8-12m/min | |

| 10mm~12mm thickness, speed suggested to 4~6m/min | |

| 15mm~19mm thickness, speed suggested to 2-3m/min | |

| 20mm and more, speed suggested to 0.5-1.5m/min | |

| Item. | Spec. |

| Main machine frame | Aluminum alloy + steel, no deformation. |

| High pressure pump | China famous brand: Shanqing |

| Frequency converter of conveying | China famous brand: Kailida |

| Brush motor | China famous brand: Jinxing |

| Bearing | China famous brand: HRE |

| Electrical Appliance | Schneider |

| Rubber roller | NBR Perduran(sour liquid forbiddion), stainless steel 304 shaft |

| Water tank, sink, side covers, all parts touch water | Stainless steel 201 |

| PLC | Siemens |

Know More

Descripción técnica

The Aluminum Alloy Structure

The whole cleaning equipment adopts aluminum alloy assembled tripod, which is stable and durable, not easy to change. The surface of the aluminum alloy aluminum profile adopts negative oxidation treatment, which is not easy to be corroded by water.

The Water Tank Adopts #201 Stainless Steel

The water tank, the shield and the place in contact with the water are made of #201 stainless steel, which is harder than #304 stainless steel and contains high manganese. Chromium-rich oxides will be formed on the surface of the steel body to protect the steel body from water rust

The Gear Transmission

The equipment adopts gear transmission as a whole, and the transmission efficiency is high, generally η=0.94~0.99; the transmission ratio has a wide range, especially when planetary transmission is used, the transmission ratio can reach 100-200 (single-stage), which is suitable for deceleration or Speed-increasing transmission; reliable operation and long service life.

The Lifting System

The lifting system is driven by a servo motor, driven by a lifting screw, and combined with a gear drive. It has the characteristics of low friction loss, high transmission efficiency, and high axial rigidity. In addition, the starting torque of ball screw pair is Smaller, there will be no crawling phenomenon like sliding motion, and it can ensure the realization of precise micro-feed and high-speed feed.

The Rubber Roller Transmission

The feeding port and the discharging port of the equipment adopt frequency conversion transmission, and the operation screen is displayed for easy operation. The rubber roller is made of high-quality nitrile rubber, driven by gears, and runs smoothly. It can be connected with edging line, hollow line and laminated line for data connection and unified control.

The Imported PLC Control System

The PLC control system can be equipped with the Taiwan Delta or Germany Siemens control system according to the actual requirements of the customer. The PLC control system can be directly connected to the network, connecting the loading and unloading CNC robots to achieve a smart factory with integrated operation.

Know More

Advantage 1. Improve the corrosion resistance of aluminum profiles

The main component of aluminum alloy profiles is aluminum, which is an active metal that reacts with oxygen in the air to produce aluminum oxide. Due to the uneven oxide film formed naturally, the oxide film is very thin, easily scratched, and has weak corrosion resistance. The artificial oxide film produced by anodizing is uniform, dense and corrosion-resistant.

Advantage 2. Improve wear resistance

The hardness of aluminum alloy cannot be compared with that of steel. The aluminum profile substrate is particularly easy to scratch and wear. The surface of the anodized industrial aluminum profile is very hard and is not easy to scratch by other objects!

Advantage 3. Improved decoration

The base color of the aluminum profile is relatively single, which cannot meet the needs of customers. To improve the aesthetics of the aluminum profile, the aluminum profile processing factory will color the surface of the aluminum profile and anodize the aluminum profile. Thereby, the color of the surface of the aluminum product is diversified.

Servicio y Demanda Personalizados

Adquisición de otras máquinas procesadoras de vidrio

Más popular- Compre otros equipos automáticos de procesamiento de vidrio (como la máquina de templado de vidrio y la máquina de vidrio aislante) y expórtelos junto con los mismos contenedores. Sin costo de abastecimiento de compra.

Instalación y orientación del equipo en el sitio

Más popular- Es necesario enviar ingenieros de servicios posventa con algunos años de experiencia con orientación sobre instalación y puesta en marcha de equipos automáticos en el sitio por 200 dólares por día con esos usuarios de terminales.

Cuidar el mantenimiento del ciclo de vida completo de los equipos

Más popular- Proporcionar una copia de los repuestos y piezas frágiles comúnmente utilizadas en la máquina automática de vidrio aislante y comprarlas juntas, se hace responsable del mantenimiento del ciclo de vida completo de la máquina automática de lavado de vidrio.

Make an Appointment for Production

- The main drive of this equipment adopts simons servo frequency conversion motor, and the brush is independently driven, with stable rotation speed and longer service life;

- The digital display shows glass thickness, working speed and other processing data;

- It is equipped with three pairs of brushes and 3 sets of independent water tank chambers, which can effectively wash the Low-E coated glass, and the special wind knife blows the glass with strong wind, which has a better air drying effect.

Primero, debe comprender sus necesidades de lavado. Esto incluye el tipo de vidrio que necesita lavar (p. ej., vidrio plano, vidrio curvo, vidrio revestido, etc.), el tamaño y grosor del vidrio y el efecto de lavado que espera. Estos factores determinarán qué tipo de lavadora necesitas.

2. Salida

Sus necesidades de producción también afectarán su elección. Si sus necesidades de producción son grandes, es posible que necesite una lavadora de vidrio eficiente y totalmente automática. Si sus necesidades de producción son pequeñas, una lavadora semiautomática o manual puede ser suficiente.

3. Presupuesto

Su presupuesto también es una consideración importante. Las lavadoras totalmente automáticas suelen ser más caras que las semiautomáticas o manuales. Debes sopesar tus necesidades y tu presupuesto para elegir el equipo que mejor se adapta a ti.

4. Marca y servicio postventa

Elegir una marca conocida normalmente puede garantizar la calidad y el rendimiento del equipo. Además, también es muy importante un buen servicio postventa. Si hay un problema con el equipo, un buen servicio posventa puede ayudarle a resolver el problema rápidamente y reducir el tiempo de inactividad.

En general, elegir una lavadora de vidrio que se adapte a sus necesidades debe considerar sus necesidades de limpieza, requisitos de producción, presupuesto, marca y servicio postventa, así como el factor de protección ambiental.

Promoción de ventas y descuentos

LIJAING Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional glass washing machine suggestions for any specific events.