How to select the secondary sealant for insulating glass: the structural adhesive.

With the improvement of modern decoration level, insulating glass is a kind of energy-saving glass that has been widely used in commercial office buildings, large shopping malls, high-rise residential buildings and other buildings. It has excellent heat insulation, sound insulation performance and is beautiful and practical. Sealant for insulating glass does not account for a high proportion of the cost of insulating glass, but it is very important for the durability and safe application of insulating glass. So how to choose the better insulating glass secondary sealant?

1. About insulating glass

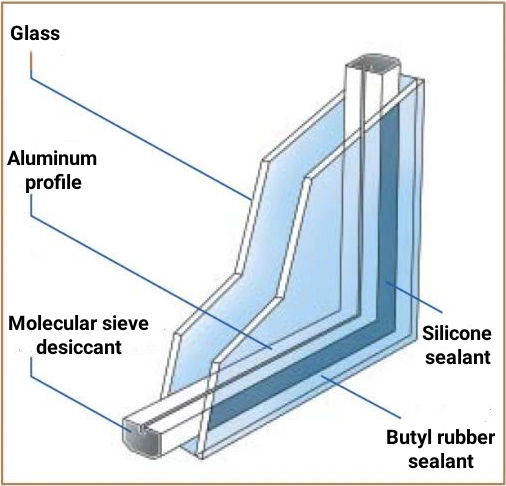

Insulated glass is made up of two (or more) pieces of glass bonded with spacers. There are two main types of sealing: the strip method and the glue bonding method. At present, the double sealant in the insulating glass sealant bonding method is the most commonly used sealing structure. The structure is as shown in the figure: two pieces of glass are separated by spacers. Butyl extruder sealant is used between the spacers and the glass for front-end sealing using a fully automatic butyl extruder coating machine. Molecular sieves are filled inside the spacers, the gap formed between the edge of the glass and the outside of the spacer is sealed with a second layer of sealant and a fully automatic insulated glass sealing robot line.

Figure 1 The Insulating Glass

Figure 2 The insulating glass sealants

The function of a sealant is to prevent water vapor or inert gases from entering and exiting the cavity. Butyl extruder sealant is generally used because the water vapor transmission rate and inert gas transmission rate of butyl extruder sealant are very low. It is the sealant between the aluminum strip side and the glass. The most effective barrier to moisture vapor. However, butyl extruder sealant itself has low bonding strength and low elasticity, so the overall structure must be fixed with a second sealant to bond the glass plates and spacers together so that the first sealant can maintain good performance when the insulated glass is under load. The sealing effect is excellent, while the overall structure is not affected.

2. Types of secondary sealants for insulating glass

There are three main types of secondary sealants for insulating glass: silicone, polyurethane and polysulfide. However, due to the poor UV aging resistance of polysulfide sealant and polyurethane sealant, if the bonding surface with the glass is exposed to sunlight for a long time, degumming will occur. This phenomenon will cause the outer piece of the insulating glass of the hidden frame glass curtain wall to fall off or the sealing failure of the insulating glass of the point-supported glass curtain wall. The molecular structure of silicone sealant makes silicone sealant have excellent high and low temperature resistance, weather resistance and UV aging resistance. It also has low water absorption, so silicone is the main product on the market.

| Sealing materials | Water vapor permeability resistance | Water vapor transmission rate | Argon gas retention capacity | UV resistance | High temperature resistance | Low temperature resistance |

| Hot melt butyl adhesive | Excellent | 0.65 | Good | Good | Good | Generally |

| Silicone sealant | Poor | ≥200 | Poor | Excellent | Excellent | Excellent |

| Polysulfide sealant | Good | 40~65 | Good | Good | Good | Good |

| Polyurethane sealant | Good | 15~40 | Generally | Good | Good | Good |

3. Hazards of improper application

The problems caused by improper selection of the secondary sealant can be divided into the following two categories: one is the loss of the use function of the insulating glass, that is, the original function of the insulating glass is lost; the other is related to the safety issues of the application of insulating glass - —That is, the safety hazard caused by the fall of the outer piece of insulating glass.

3.1 Loss of function of insulating glass

The common reasons for insulating glass seal failure are:

- Butyl extruder sealant itself has quality problems or is incompatible with silicone sealant;

- The insulating glass is filled with mineral oil with a secondary sealant;

- Contact with oil-filled sealant, such as weather-resistant sealant for curtain wall joints or sealant on doors and windows;

- Other factors such as desiccant or processing technology.

Figure 3 The condensation phenomenon on insulating glass

The sealing failure of insulating glass occurs. After several years of use, the insulating glass will show obvious condensation and water accumulation, and prematurely lose the effects of heat insulation, sound insulation and waterproofing. These problems are closely related to the quality of butyl glue, molecular sieve quality and processing technology used to seal the insulating glass, but the quality and performance of the second sealant cannot be ignored. Because the insulating glass structure must rely on two layers of sealant to fix the overall structure, bonding the glass panels and spacers together. Some insulating glass glue manufacturers lack experience in product formulas or have low quality control levels, resulting in fluctuations in product performance. The second sealant has poor adhesion to the glass and spacers, or has compatibility with the first seal butyl extruder sealant. Problems seriously affect the service life of insulating glass.

Figure 4 The insulated glass "oil flow" phenomenon

The most common reason for the failure of insulating glass due to silicone glue is: the secondary sealing silicone glue used for insulating glass is inferior and cheap oil-filled sealant. Will the oil filling of the secondary sealant of insulating glass cause the failure of the insulating glass?

In order to reduce costs, some insulating glass secondary sealants on the market are filled with a certain amount of mineral oil. Mineral oil, commonly known as white oil, is an alkane-based substance that has poor compatibility with silicone sealant. After a certain period of time, it will migrate and ooze out, forming "iridescence" or "oil flow", which will eventually lead to the failure of the insulating glass. The cause of the "iridescence" phenomenon is the migration of mineral oil into the inner cavity of the insulating glass. The reason for the "oil flow" phenomenon is that mineral oil migrates and dissolves the sealing butyl glue of the insulating glass, resulting in black oil spots or stains.

Because silicone base polymers account for a large proportion of the cost of silicone sealants, reducing the content of silicone base polymers can reduce costs. Unscrupulous manufacturers use some low-priced mineral oil to replace the silicone base polymer. At the same time, mineral oil also has the effect of significantly reducing the viscosity of the sealant. Therefore, a large amount of fillers can be filled in the formula to further reduce the content of the silicone base polymer. The excellent weather resistance of silicone sealants is due to the silicone base polymer containing silicon-oxygen bonds as the main chain. If the content of the silicone base polymer decreases, the durability of the silicone sealant will inevitably decrease, thus affecting the service life of insulating glass.

3.2 The outer piece of insulating glass falls

Figure 5 The outer piece of insulating glass building curtain walls falling

Insulating glass is widely used on building curtain walls, and the second sealant must be used according to specifications. The outer glass of the insulating glass curtain wall often falls, seriously endangering personal safety. The phenomenon of glass falling from the outer piece of insulating glass of glass curtain wall mainly exists in the fixed and opening parts of hidden frame, semi-hidden frame glass curtain wall or the opening part of exposed frame glass curtain wall. Especially in windy weather or after rainy days, the phenomenon of glass falling is more serious.

In the identification of curtain wall quality accidents, it was found through analysis that there are three main reasons for the fall of the outer glass:

- Compatibility issues of secondary sealants for insulating glass;

- In order to save costs, the relevant parties blindly pursue low prices. The secondary sealant of insulating glass uses non-silicone structural sealant, such as polysulfide rubber and silicone construction sealant;

- The problem of the injection width of the secondary sealant for insulating glass caused by the unprofessional and imprecise nature of some construction workers.

- Things to note when selecting glue for secondary sealing.

The secondary sealant used for insulated glass has a great impact on the quality and service life of insulated glass. The structural sealant used for insulated glass is even directly related to curtain wall safety issues. Therefore, we must not only choose good products, but also choose the right products.

4.1 Comply with standards and use as needed

- The secondary sealant for insulating glass of hidden frame curtain walls and semi-hidden frame curtain walls must use silicone structural sealant, and the size must be calculated based on the international industry standard "Technical Specifications for Glass Curtain Wall Engineering";

- The secondary sealant for the insulating glass of the point-supported glass curtain wall must use silicone structural sealant;

- It is recommended to use insulating glass silicone structural adhesive for the secondary sealant of insulating glass for large-size open-frame curtain walls;

- The secondary sealant for insulated glass for doors, windows and ordinary open-frame curtain walls can be insulated glass silicone sealant, polysulfide sealant or polyurethane sealant.

Since the secondary sealant for insulating glass used in hidden frame, semi-hidden frame and point-supported glass curtain walls bears the wind load and self-weight load of the outer glass, the sealant is required to have a high bonding strength.

Although both silicone sealant and polysulfide sealant have high bonding strengths, polysulfide sealant has poor UV resistance and poor compatibility with silicone sealant for curtain walls. Therefore, hidden frame and semi-hidden frame for insulated glass that bears load such as point-supported glass curtain walls, the second sealant must use silicone structural sealant.

Since most insulating glass manufacturers are not very clear or understand the performance index requirements of insulating glass when used in building curtain walls and other applications, in addition, curtain wall construction companies cannot specify the quality of the customized insulating glass secondary sealant when customizing insulating glass. The particularity is pointed out to the insulating glass manufacturing enterprises. The use of polysulfide sealant by such manufacturing enterprises is also one of the main reasons for the outer glass of the insulating glass to fall off.

In addition, in the exposed frame glass curtain wall, polysulfide sealant can be used as the secondary sealant for the fixed plate insulating glass, but many people ignore the opening part. This is because the opening part of the exposed frame glass curtain wall is designed according to the hidden frame structure. This point is often ignored by most curtain wall companies. The secondary sealant of the opened part of the insulated glass does not use silicone structural sealant, causing the outer piece of the insulated glass to fall seriously in the open part of the open-frame glass curtain wall.

4.2 Do not use oil-filled sealant

As market competition becomes increasingly fierce, some unscrupulous manufacturers seek short-term profits at the expense of sealant product performance and quality in order to reduce production costs. Filling with cheap "mineral oil" instead of expensive silicone base polymer is a common method used by unscrupulous manufacturers to reduce sealant production costs. Hidden behind the low durability of cheap oil-filled glue is the premature failure of the insulating glass or even the fall of the outer piece of the insulating glass, which may cause safety hazards such as heavy losses. Therefore, everyone must refuse to use "oil-filled glue".

4.3 Choose brand products with good reputation and good service

It is a silicone sealant company that integrates upstream and downstream resources. 95% of the production raw materials have been supplied in the park, realizing the realization of raw material. For pipeline transportation in the production workshop, the production technology is mature, the degree of automation is high, and the production control and quality control are strict. The related products have been recommended by the structural adhesive industry and green building materials and many other certifications, and are trustworthy.

Figure 6 The secondary sealant of insulating glass: the structural adhesive

The secondary sealant of insulating glass does not account for a high proportion of the cost of insulating glass, but it is very important for the durability and safe application of insulating glass. It is recommended that all customers choose the right products. If you pursue low prices and ignore the correct application and quality assurance of the products, it may lead to quality problems in curtain wall doors and windows, and even cause major safety accidents.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.