Zweikomponenten-Dichtstoff-Auftragsmaschine für Isolierglas

LIJIANG Glas

Weitere Details der automatischen Ausrüstung

Grundlegendes Arbeitsprinzip

Anwendung

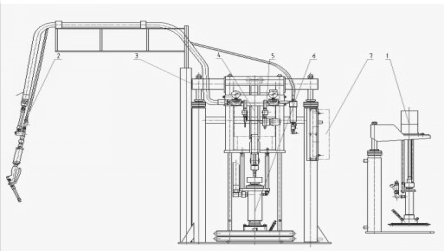

Diese Art Isolierglas-Zweikomponenten-Dichtungsmittel-Verteilmaschine wurde durch fortschrittliche Technologie aus dem Ausland und innerhalb Chinas entwickelt. Es handelt sich um eine spezielle Ausrüstung, die zum Auftragen des Zweikomponenten-Polysulfidklebers und/oder des Zweikomponenten-Silikonstrukturklebers für Isolierglas vom Aluminiumtyp oder Glas für Vorhangfassaden verwendet wird. A- und B-Pumpe nehmen die Korea-Marke HASCO an. So kann sie den zuverlässigen Arbeitseffekt gewährleisten.

Ein spezielles und praktisches Mischgerät kann das hochwertige Mischen des Zweikomponenten-Polysulfidklebers und/oder des Zweikomponenten-Silikonstrukturklebers sicherstellen. Dieses Gerät zeichnet sich durch eine gleichmäßige Mischung und kontinuierliche Stabilität des extrudierten Leims, eine gute Streuwirkung und eine hohe Produktionseffizienz aus.

Diese Art Isolierglas-Zweikomponenten-Dichtungsmittel-Verteilmaschine wurde durch fortschrittliche Technologie aus dem Ausland und innerhalb Chinas entwickelt. Es handelt sich um eine spezielle Ausrüstung, die zum Auftragen des Zweikomponenten-Polysulfidklebers und/oder des Zweikomponenten-Silikonstrukturklebers für Isolierglas vom Aluminiumtyp oder Glas für Vorhangfassaden verwendet wird. A- und B-Pumpe nehmen die Korea-Marke HASCO an. So kann sie den zuverlässigen Arbeitseffekt gewährleisten.

Ein spezielles und praktisches Mischgerät kann das hochwertige Mischen des Zweikomponenten-Polysulfidklebers und/oder des Zweikomponenten-Silikonstrukturklebers sicherstellen. Dieses Gerät zeichnet sich durch eine gleichmäßige Mischung und kontinuierliche Stabilität des extrudierten Leims, eine gute Streuwirkung und eine hohe Produktionseffizienz aus.

Detaillierte Arbeitsschritte

Main Feature

1.Imported motor system to improve equipment efficiency

2.Imported sealant gun, stainless steel mixer

3.High pressure protect device

4.Mixed rate detector

5.Anti-back flow control structure

6.Important control parts adopt Korea Brand

7.Mixed rate detector can control the rare of two kinds of glue

It adopts the most advanced domestic and international technologies, which is applicable to sealing and bonding of insulating glass and curtain wall glass as well as machinery manufacturing.

The internationally prevailing stationary reciprocating mixer is used in this machine, with the specially designed needle valve, a much better mixing result is achieved; The special material with elasticity is used to make the dispensing nozzle, the production of insulating glass is more convenient, simple and elegant.

The material pump, curing agent pump and proportional pump high pressure valve of the machine are made of special leakage-free alloy by grinding. The proportional pump is installed with an adjustable proportioning mechanism; the nearly fastidious proportioning requirements of the bi component adhesive are fulfilled, as well as those of curtain wall glass and insulating glass.

The curing agent system is fully closed, which prevents the agent from contacting air and therefore solidification occurs. The fluid flow rate stability is ensured and mixing effect improved.

The key functional parts are made of high-tension and quality stainless steel with thermal treatment, the reliability and durability of the machine are greatly improved, ensuring a fairly well quality of machine.

Component A pump and Component B pump are driven by high quality imported pneumatic systems respectively. With the contact-free electrical control system, a reliable and sensitive switching of direction is realized.

1.Imported motor system to improve equipment efficiency

2.Imported sealant gun, stainless steel mixer

3.High pressure protect device

4.Mixed rate detector

5.Anti-back flow control structure

6.Important control parts adopt Korea Brand

7.Mixed rate detector can control the rare of two kinds of glue

It adopts the most advanced domestic and international technologies, which is applicable to sealing and bonding of insulating glass and curtain wall glass as well as machinery manufacturing.

The internationally prevailing stationary reciprocating mixer is used in this machine, with the specially designed needle valve, a much better mixing result is achieved; The special material with elasticity is used to make the dispensing nozzle, the production of insulating glass is more convenient, simple and elegant.

The material pump, curing agent pump and proportional pump high pressure valve of the machine are made of special leakage-free alloy by grinding. The proportional pump is installed with an adjustable proportioning mechanism; the nearly fastidious proportioning requirements of the bi component adhesive are fulfilled, as well as those of curtain wall glass and insulating glass.

The curing agent system is fully closed, which prevents the agent from contacting air and therefore solidification occurs. The fluid flow rate stability is ensured and mixing effect improved.

The key functional parts are made of high-tension and quality stainless steel with thermal treatment, the reliability and durability of the machine are greatly improved, ensuring a fairly well quality of machine.

Component A pump and Component B pump are driven by high quality imported pneumatic systems respectively. With the contact-free electrical control system, a reliable and sensitive switching of direction is realized.

Technische Parameter

Main Technical Parameter

| Item. | Spec. |

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |

| Weight | 490kg |

| Capacity of the glue drum | 200-300 ml/200 kg |

Technische Beschreibung