LJTJ2030 Automatische vertikale Isolierglas-Versiegelungsrobotermaschine

Die automatische vertikale Isolierglas-Versiegelungsrobotermaschine LIJIANG Glass LJTJ2030 zeichnet sich durch eine vollständig isolierende Glasversiegelungskante, keine Blasen, eine präzise Steuerung der Versiegelungsleistung, eine hohe Produktionseffizienz, eine geringe Arbeitsintensität und konsistente Versiegelungswirkungsstandards aus, die von den Benutzern gut angenommen werden.

- Verkäufer: LIJIANG Glas

- Versand:

Erfahren Sie mehr

LJTJ2030 Automatic Vertical Insulating Glass Sealing Robot Equipment

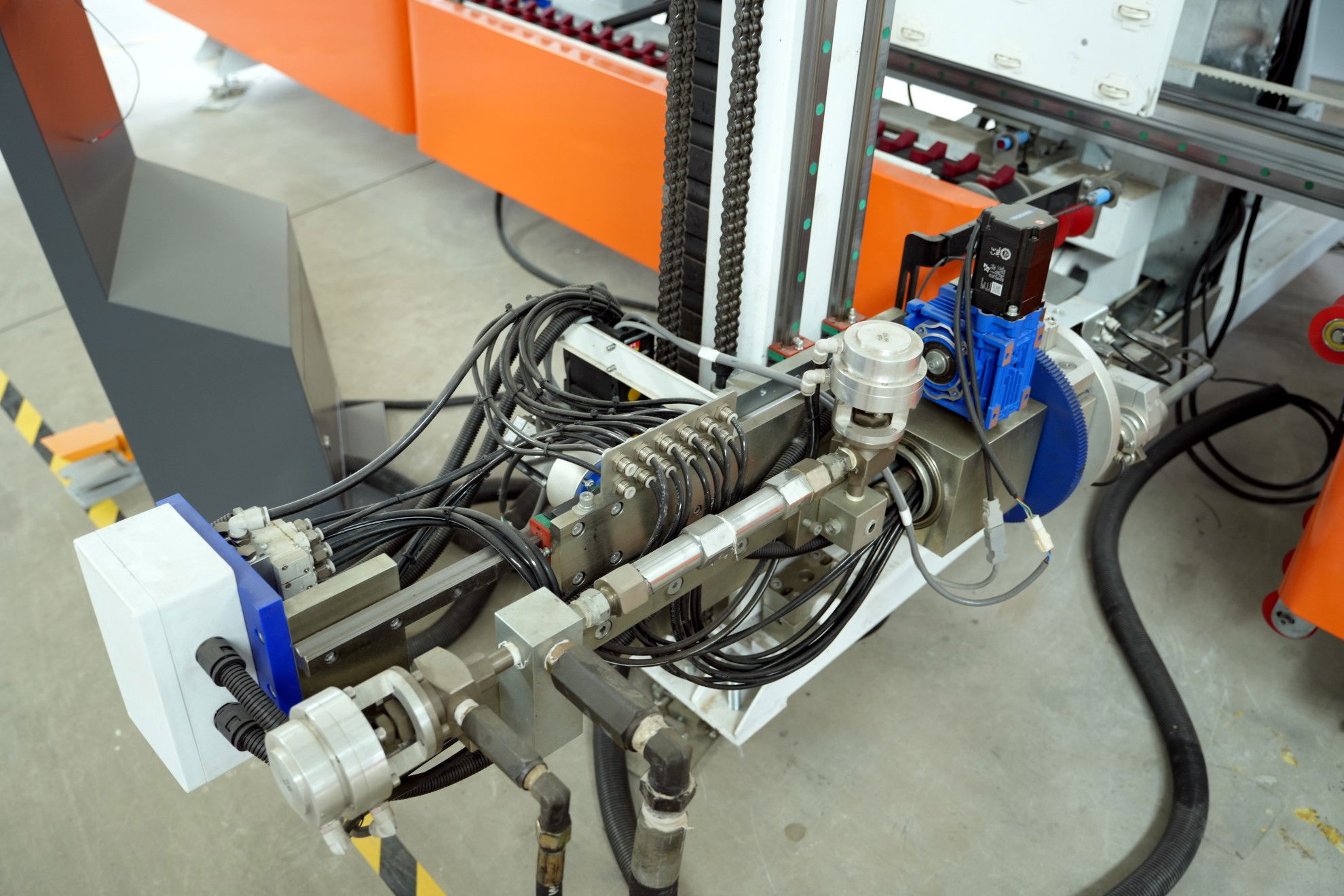

LJTJ2030 Automatic Vertical Insulating Glass Sealing Robot Equipment adopts a large-screen touchscreen human-machine interface control system to realize automatic positioning of aluminum partitions, automatic pressing, conveying, automatic lifting and lowering of secondary sealant sealing, automatic timing heating, and other functions.

The use of advanced gas-liquid boosting technology makes the system pressure more stable and energy-saving. The system is equipped with an alarm system for running out of secondary sealant sealing, and a dual-group and dual-sealant sealing supply configuration. Production will not be delayed during sealant sealing replacement. The glue head is adjustable within the range of 6-20mm and can be fine-tuned up and down.

Equipped with a thickness detection device and a depth detection device, the thicknsess and depth of the glass can be automatically detected through high-resolution precision sensors, thereby better saving raw materials. Coupled with the automatic sealant replenishing function and automatic adjustment of two-component sealant output, the production efficiency can be greatly improved.

Benefits & Advantages

- Suitable for large-scale glass deep processing enterprises to reduce production labor intensity, save manpower and improve production efficiency.

- Full intelligent touch human-machine interface, simple and convenient operation.

- The servo control system adopts world-renowned brands and has stable performance.

- Synchronous belt transmission ensures smooth glass transportation and precise positioning.

- The key components of the equipment are made of special materials. The operation of the equipment is stable and reliable and the service life is long.

- After sealing, the periphery of the glass is plump and free of air lines, the corners are full, and the surface is smooth without the need for corner trimming.

- It can be equipped with two sets of sealant supply systems, and the two sealants can be switched quickly and with one-button operation.

- Supports three-layer insualting glass sealant coating.

Main Technical Parameter

| Item. | Spec. |

| Max. glass processing size | 2000*3000mm |

| Min. glass processing size | 400*280mm |

| Glass thickness | 3-15mm |

| Diameter of grinding wheel | 200mm |

| Conveyor height | 500mm |

| Edge deleting width | 10-50mm |

| Transmission speed | 29m/min |

| Edge deleting speed | 2-29m/min |

| Abrasive wheel width | 10/12/15mm |

| Grinding wheel speed | 0~3000r/min |

| Total air consumption | 100L/ min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50Hz 3.35Kw |

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.